6G radome suitable for terahertz antenna and preparation method thereof

A radome and terahertz technology, applied in the directions of antennas, antenna parts, radiation unit covers, etc., can solve the problems of insubstantial reports, limit the heat resistance of radomes, and less 6G radomes, so as to reduce mutual The effect of interference, reducing the difficulty of the preparation process and improving the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention provides a kind of preparation method of described 6G radome in the second aspect, and this preparation method comprises the following steps:

[0052] (1) Melting and impregnating the quartz fiber fabric with the polyphenylene ether modified bisphenol M cyanate resin to obtain a prepreg. Melting can be at 60-70°C (it can be any value within this range, for example, it can be 60°C, 61°C, 62°C, 63°C, 64°C, 65°C, 66°C, 67°C, 68°C, 69°C , 70°C).

[0053] (2) Put the foam core layer on the mold, heat and pre-shape.

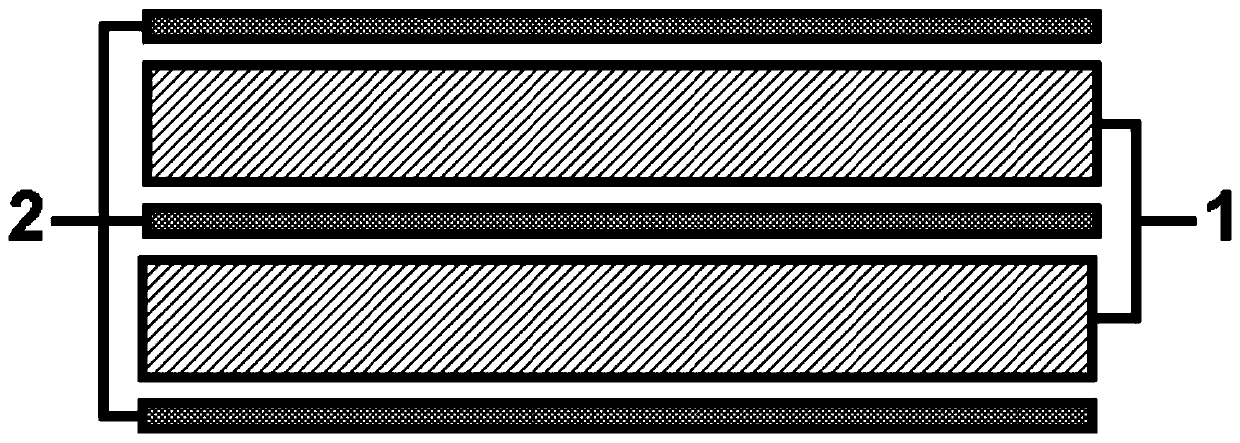

[0054] (3) Lay the prepreg prepared in step (1) and the foam core layer treated in step (2) sequentially in the order of inner skin, foam core layer, middle skin, foam core layer, and outer skin form a sandwich structure.

[0055] (4) Autoclave heating and pressurized curing molding, the curing temperature is preferably 80-130°C, which can be any value within this range, for example, it can be 80°C, 85°C, 90°C, 95°C, 100°C, 105°C, 110°C...

Embodiment 1

[0059] This embodiment provides a preparation method of polyphenylene ether modified bisphenol M cyanate resin.

[0060] Specifically include the following steps:

[0061] Weigh 280g of bisphenol M-type cyanate monomer into the flask, and carry out prepolymerization reaction at 150°C under the protection of nitrogen. Then, 41.8 g of polyphenylene ether was weighed and added into the flask, and stirred evenly at 110°C. Subsequently, 0.193 g of transition metal catalyst was added at 80° C. and stirred evenly.

[0062] The dielectric constant of the product is ≤2.6, and the loss factor is ≤0.004.

Embodiment 2

[0064] This embodiment provides a preparation process for a 6G radome with a C sandwich structure.

[0065] The structure of the 6G radome includes an outer skin, a foam core layer, a middle skin, a foam core layer and an inner skin in turn, and the outer skin is covered with an outer paint layer, and the components of the outer paint layer include epoxy-based putty, ring Oxygen two-component primer and fluoroplastic topcoat.

[0066] Skin (outer skin, middle skin and inner skin) material: quartz fiber (quartz fiber braid) reinforced polyphenylene ether modified cyanate (prepared according to Example 1) composite material.

[0067] Core material: PMI closed cell foam.

[0068] The specific preparation methods include:

[0069] S1. Melt the polyphenylene ether modified bisphenol M cyanate resin at 60°C and impregnate the quartz fiber braid, and control the impregnation conditions to obtain a prepreg with a glue content of 35wt%.

[0070] S2. Put the foam core layer on the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com