Sheathed line swelling detecting device and method

A detection device and sheathed wire technology, applied in the direction of mechanical diameter measurement, mechanical roughness/irregularity measurement, light guide, etc., can solve the problems of uneven thickness, market loss, production line speed out of control, etc., to avoid traction machine failure , Easy operation and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

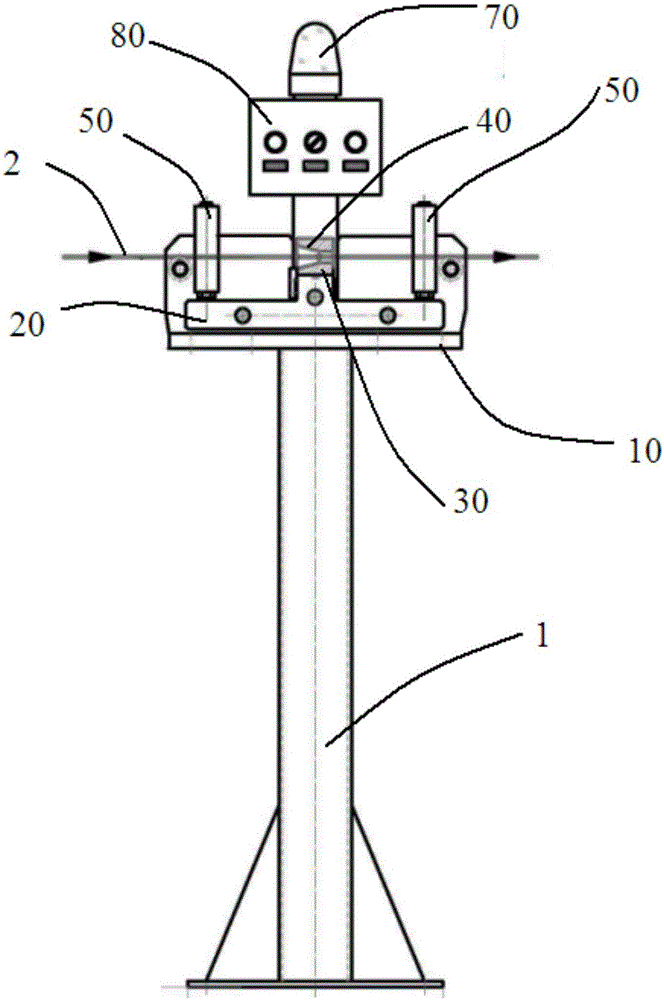

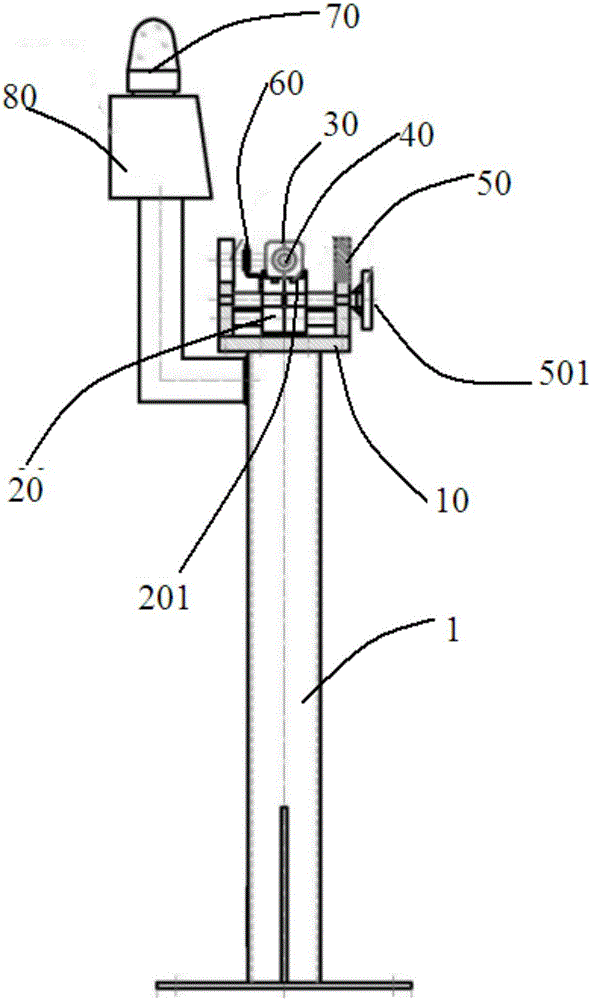

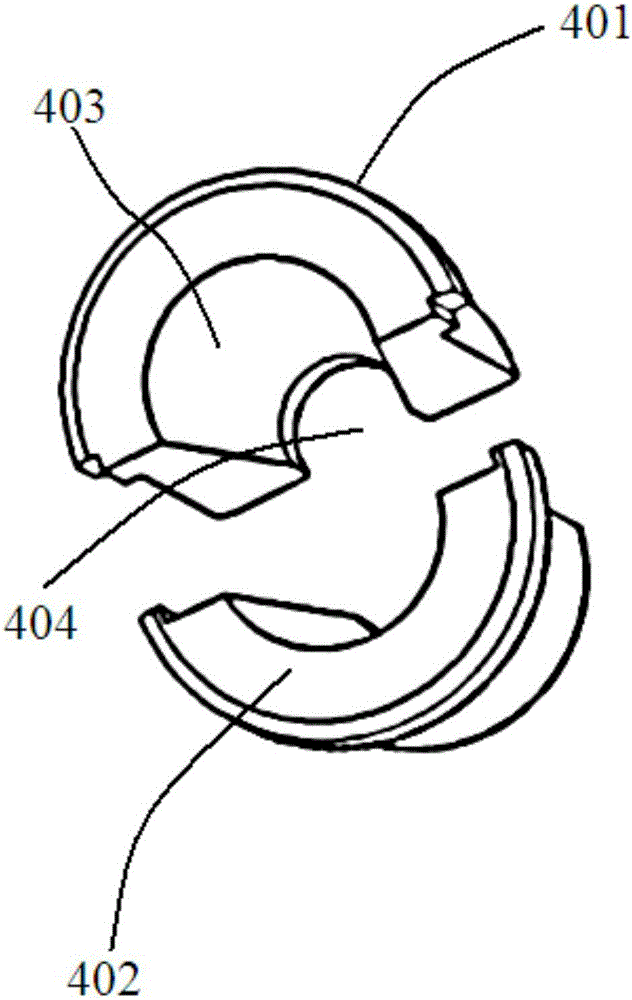

[0031] refer to Figure 1-2 As shown, a sheath wire bulge detection device is disclosed in this embodiment, and its supporting structure is a vertical frame 1. The top surface of the frame 1 is a detection workbench 10, on which a There is a base 20, a groove is provided on the end surface of the base 20, a magnet 201 is embedded in the groove, a mold base 30 is arranged on the top surface of the base 20, the magnet 201 absorbs the mold base 30, The two sides of above-mentioned mold base 30 are respectively provided with a group of guide rods 50, and cable 2 is inputted through two groups of above-mentioned guide rods 50 by wire-passing wheel, and two groups of above-mentioned guide rods 50 clamp cables; above-mentioned guide rods 50 can effectively prevent protection Set of jitter. It also effectively prevents the mold from entering the tractor and causing the tractor to fail when it does not fall off in time.

[0032] In this embodiment, the above-mentioned base 20 is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com