Automatic down filling method and automatic down filling equipment

An automatic and equipment technology, applied in the direction of sewing tools and other directions, can solve the problems of slow down filling, increase labor costs, and a lot of labor, and achieve the effects of saving labor costs, reducing the probability of illness, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

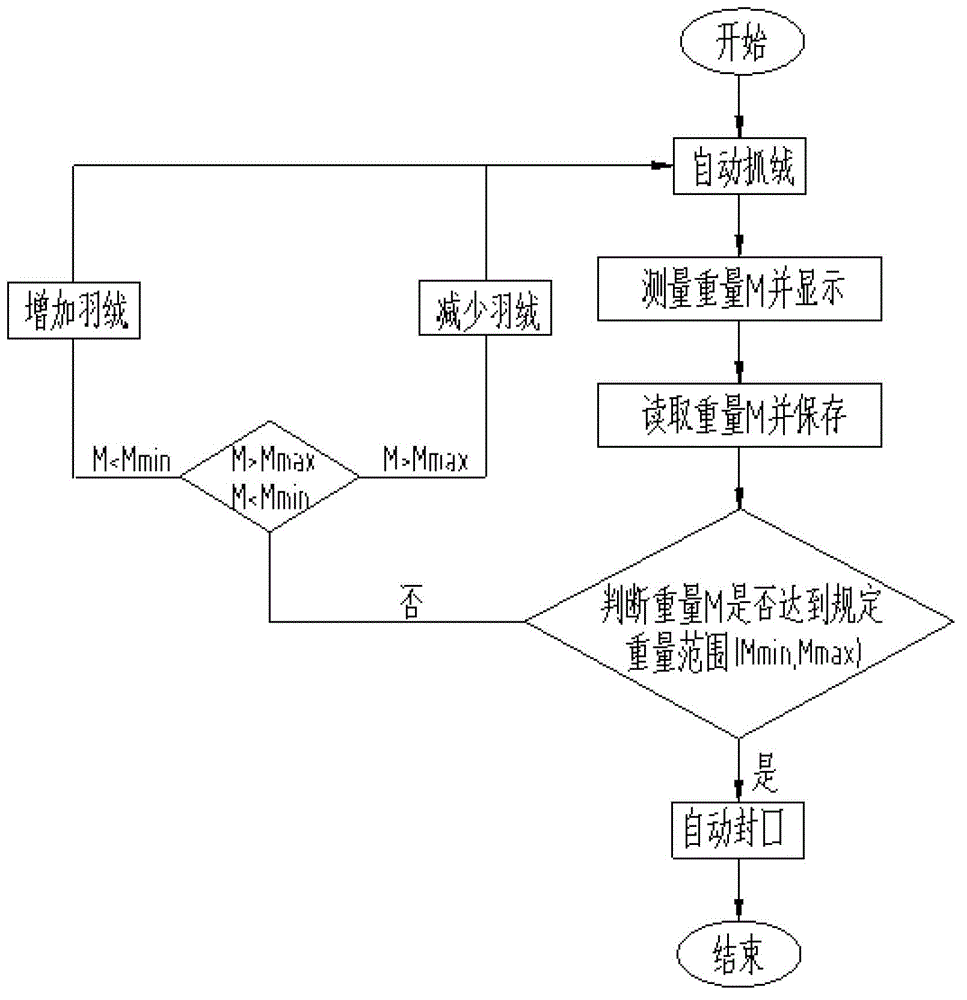

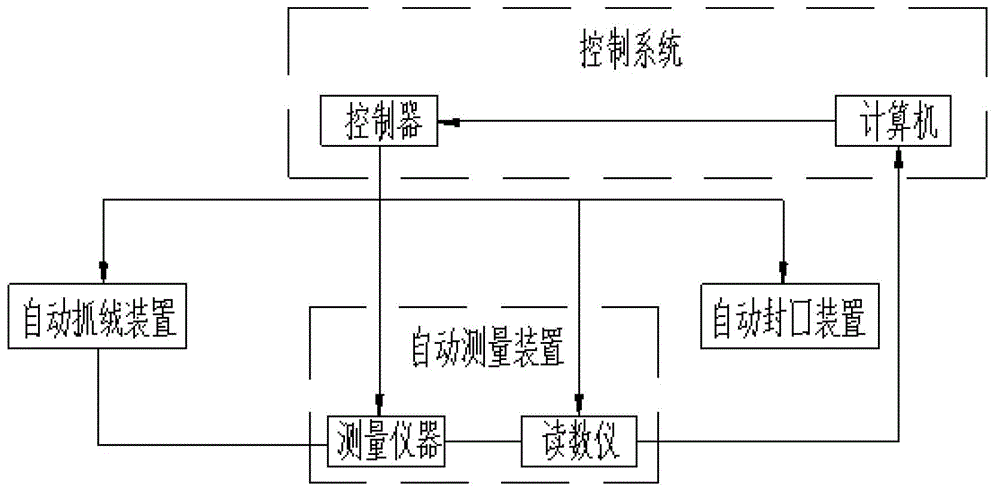

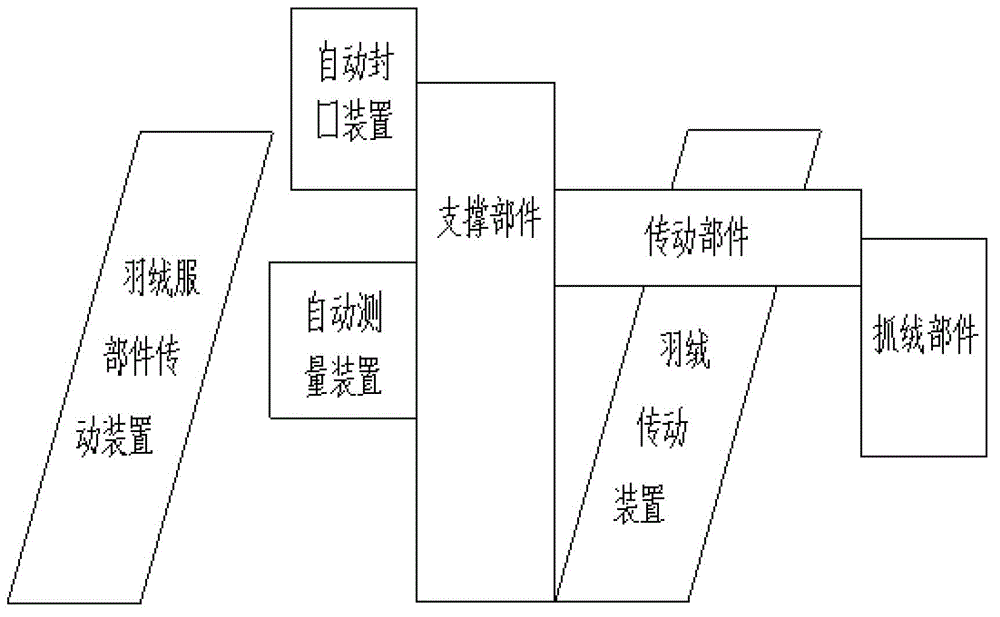

[0036] like figure 2 , image 3 As shown, the present invention provides an automatic down filling device, which includes an automatic fleece device, an automatic measuring device, an automatic sealing device and a control system respectively connected to the above three devices. Among them, the automatic down filling equipment grabs the down into or out of the down jacket parts; the automatic measuring device measures and saves the weight of the down jacket parts filled with down; The weight of the down jacket parts with down, and judge whether the weight reaches the specified weight range, and at the same time control the automatic fleece device to increase or decrease the down according to the judgment results, so that the weight of the down jacket parts with down can reach the specified weight range; and the automatic sealing device, under the control of the control system, seals the down jacket parts with the weight reaching the specified weight range.

[0037] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com