A pillow filling machine

A pillow core and component technology, which is applied in the production of home appliances, furniture covers, interior decoration, etc., can solve the problems of slow replacement of pillow cores, reduced down filling of pillowcases, and low down filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

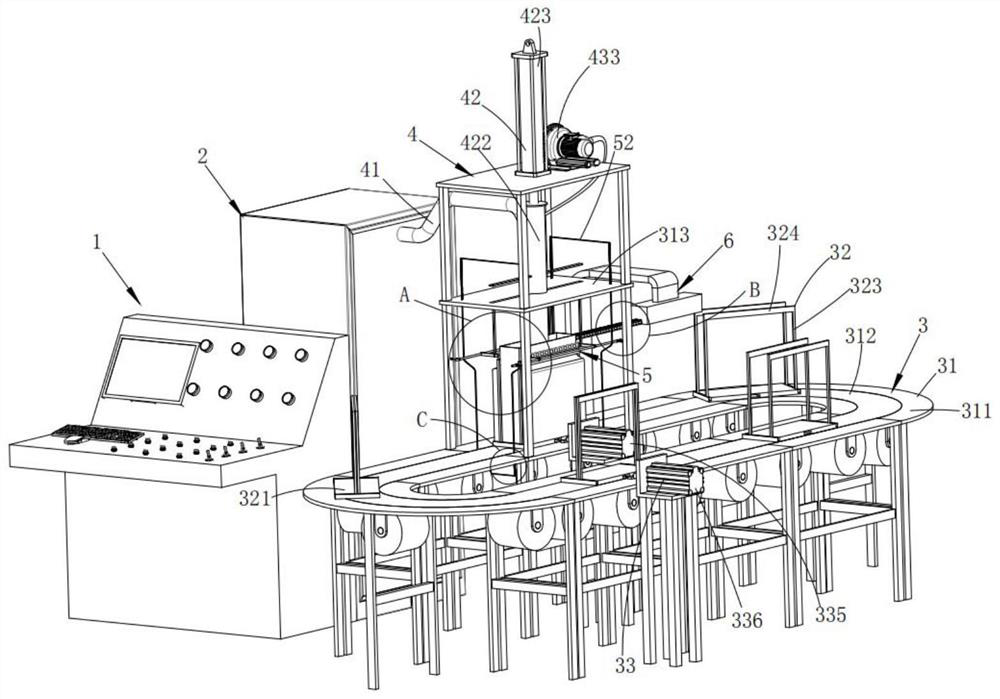

[0041] Such as figure 1 As shown, a pillow filling machine includes a console 1 and a filling machine 2, and also includes:

[0042] A bag supporting device 3, the bag supporting device 3 includes a transportation assembly 31, a fixing assembly 32 and a limiting assembly 33, and several of the fixings 32 are arranged on the transportation assembly 31 along the conveying path of the transportation assembly 31; The bit assembly 33 is provided in one-to-one correspondence with the fixed assembly 32, and it is located at the bottom of the fixed assembly 32;

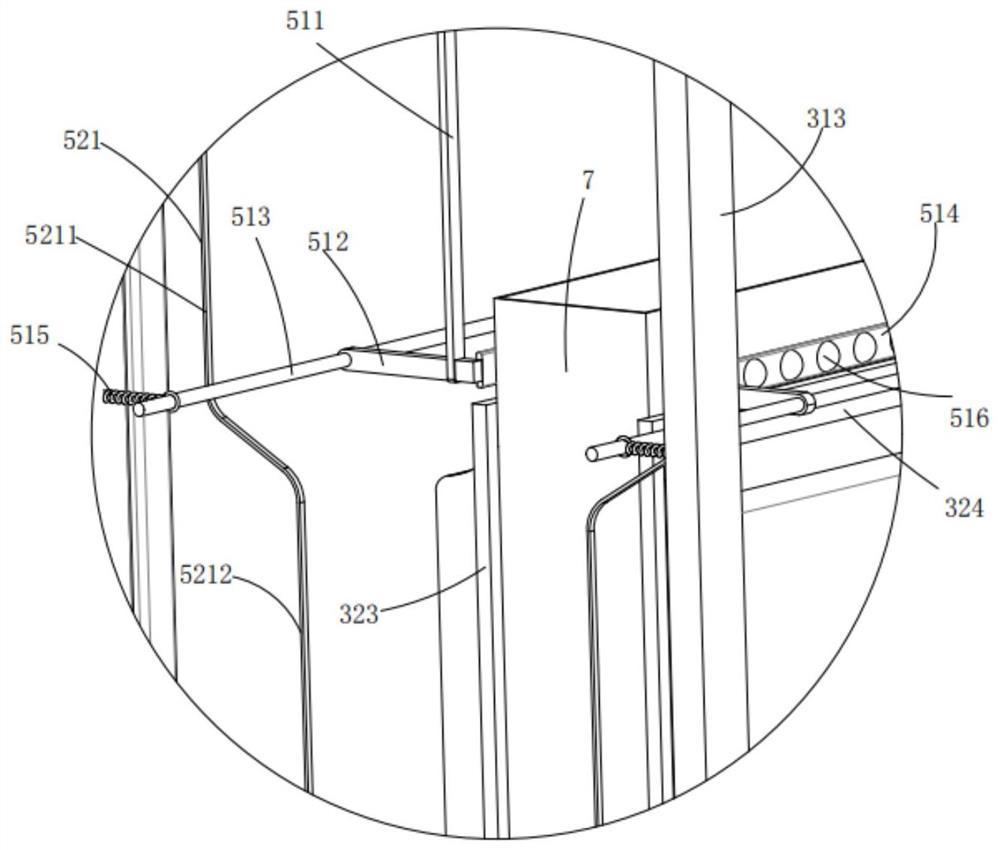

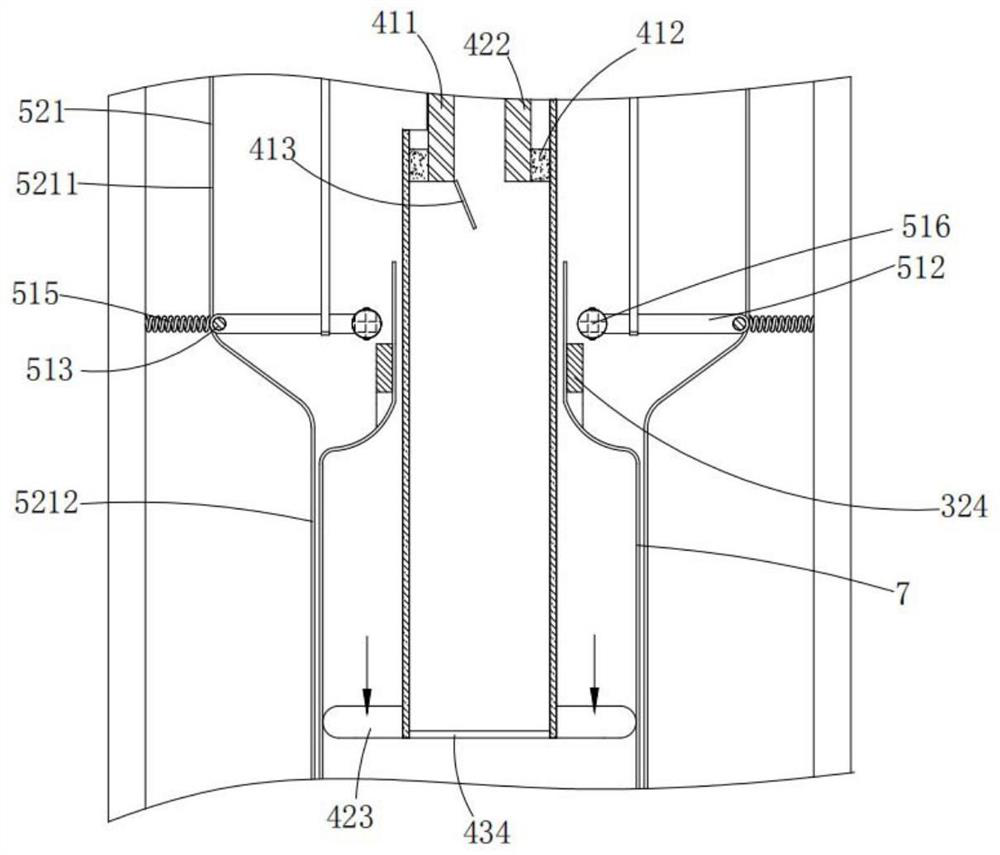

[0043] Cotton adding device 4, described cotton adding device 4 comprises feeding assembly 41, driving assembly 42 and pressing assembly 43, and described feeding assembly 41 is fixed on the conveyance path of described transportation assembly 31 just above, and it and described filling The fleece machine 2 is connected; the drive assembly 42 is slid up and down on the outside of the feed assembly 41; the press assembly 43 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com