A kind of filling method of down jacket down material

A filling method and technology for down jackets are applied in the direction of sewing tools, textiles, papermaking, sewing equipment, etc., which can solve the problems of poor effect and low efficiency of down filling methods, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

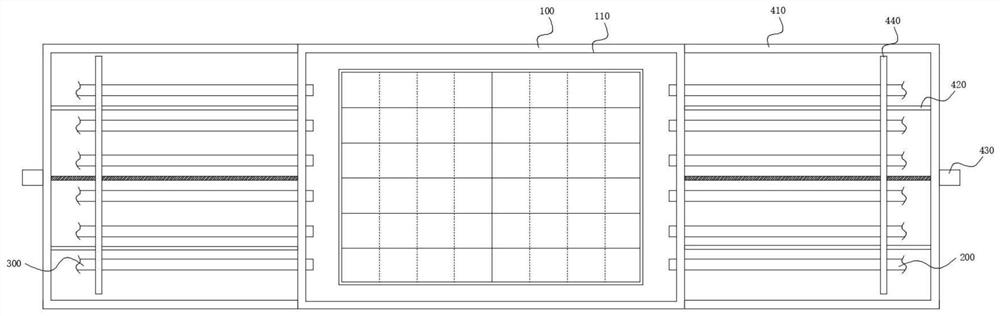

[0065] As an optimized solution of Embodiment 1, the down filling tube moving assembly 400 includes a support frame 410 connected to the side wall of the processing table 100, and a first transverse ball wire is connected between the support frame 410 and the side wall of the processing table 100. The bar module 430 and some first guide rods 420, the first guide rod 420 slides through the moving plate 440, the moving plate 440 is connected with the ball nut of the first ball screw module 430, the first down filling tube 200, The second down filling tube 300 runs through the moving plate 440 and is fixedly connected with the moving plate 440 .

[0066] This embodiment is implemented in such a way that the first ball screw module 430 provided can drive the moving plate 440 to move, and the moving plate 440 drives the first down filling tube 200 and the second down filling tube 300 in the first positioning hole 210, The movement in the second positioning hole 310 , and the first ...

Embodiment 3

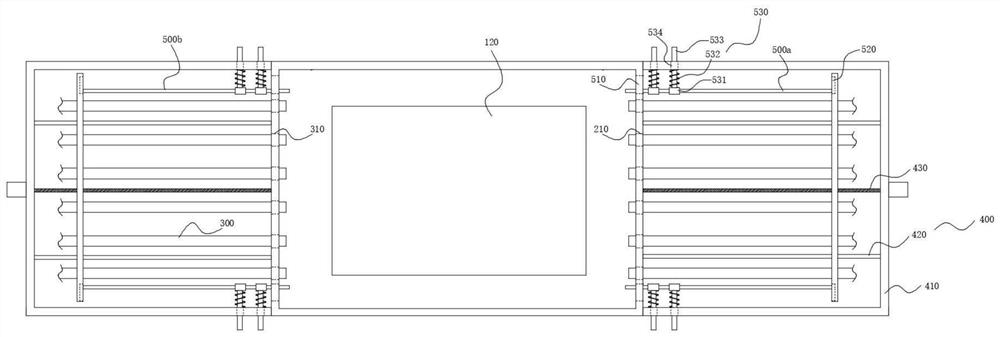

[0068] As an optimization scheme of the second embodiment, the positions corresponding to the first slide bar 500a and the second slide bar 500b on the side wall of the positioning groove 110 are respectively provided with longitudinally distributed moving holes 510, and the moving plate 440 corresponds to the first slide bar 500b. The positions of the rod 500a and the second sliding rod 500b are respectively provided with moving grooves 520 distributed longitudinally, and the ends of the first sliding rod 500a and the second sliding rod 500b are respectively slidably connected to the moving grooves 520 .

[0069] This embodiment is implemented in such a way that the movement of the moving plate 440 can drive the first sliding bar 500a, The second slide bar 500b moves, so that the first slide bar 500a and the second slide bar 500b move simultaneously with the first down filling tube 200 and the second down filling tube 300 to realize synchronous movement.

Embodiment 4

[0071] As an optimized solution of the third embodiment, the elastic tensioning assembly 530 includes a sliding sleeve 531 slidingly sleeved on the first sliding rod 500a or the second sliding rod 500b, and a sliding hole 534 penetrating the support frame 410. The sliding sleeve 531 It is connected with the support frame 510 through the first spring 532 , and the sliding sleeve 531 is provided with a positioning rod 533 , and the positioning rod 533 slides through the first spring 532 and the sliding hole 534 .

[0072] This embodiment is implemented in such a way that the first spring 532 can apply a pulling force to the sliding sleeve 531, so that the sliding sleeve 531 drives the first sliding rod 500a and the second sliding rod 500b to move to the side wall of the support frame 410, because the moving hole 510 and the moving groove 520 are longitudinally distributed, so the first sliding rod 500a and the second sliding rod 500b can move in the moving hole 510 and the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com