The structure of the filling tube for the filling machine

A down filling machine and tube structure technology, applied in the field of down product filling equipment, can solve the problems of affecting down filling speed, affecting down filling efficiency, length extension, etc., achieving a simple overall structure, ensuring down filling efficiency, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

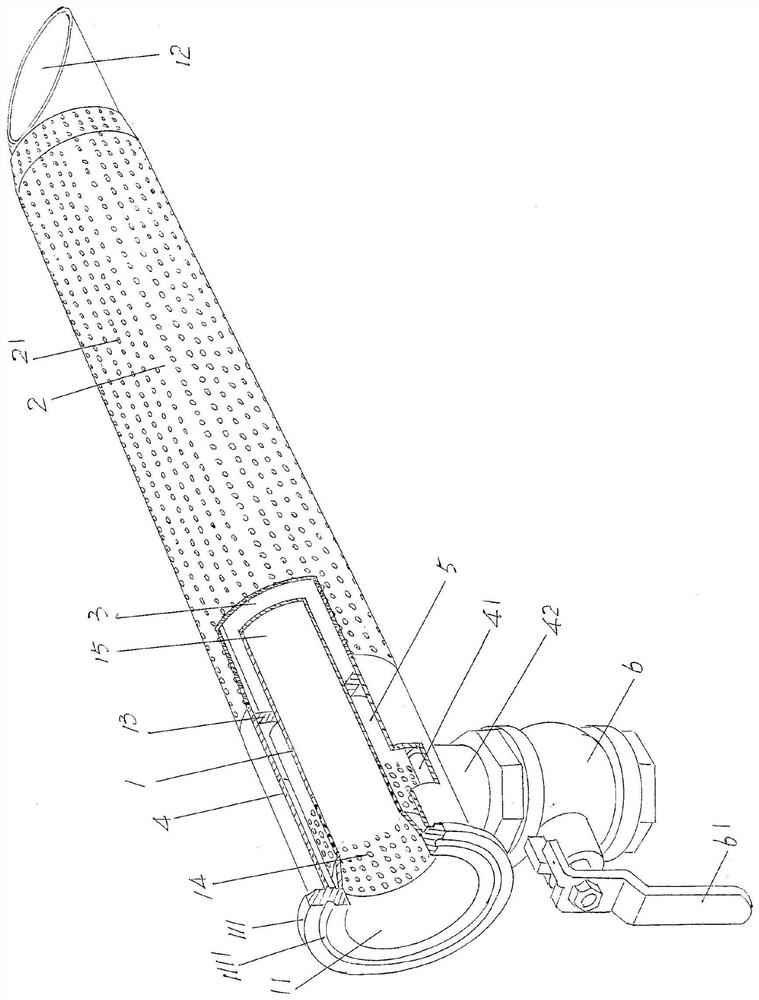

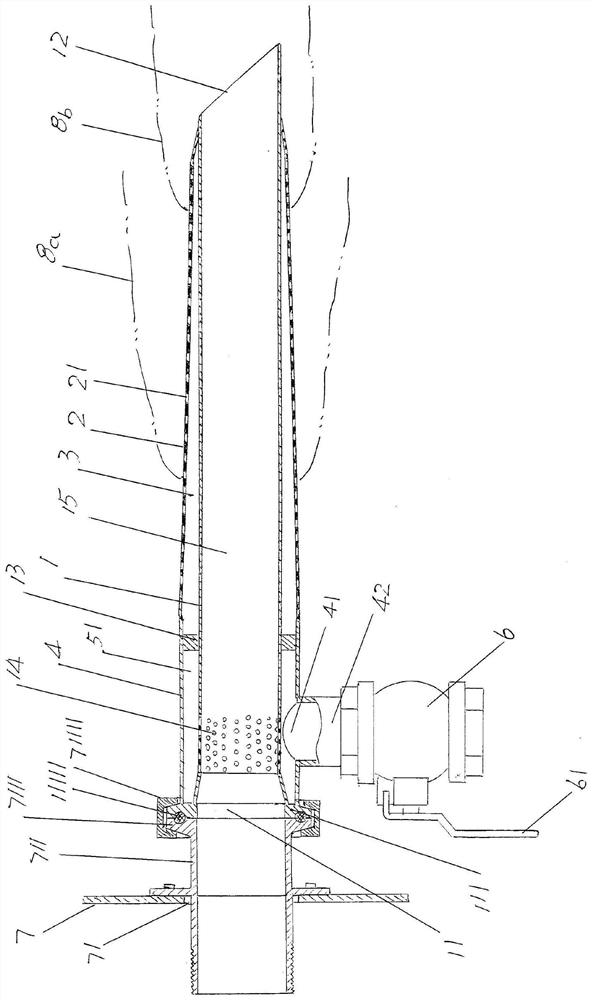

[0024] See figure 1 , shows a fleece tube 1, the left end of the fleece tube 1 is formed with a fleece tube inlet 11, and the right end of the fleece tube 1 is formed with a fleece tube outlet 12; Trachea 2, the exhaust tube 2 is located outside the aforementioned fleece tube 1 and the left end and the right end of the exhaust tube 2 are closed, and an exhaust chamber 3 is formed between the inner wall of the exhaust tube 2 and the outer wall of the fleece tube 1, and the exhaust chamber 3 It communicates with the outside world through the vent hole 21 of the vent tube 2 opened on the vent tube 2 .

[0025] As the technical point of the technical solution provided by the present invention: a spacer 13 is fixed on the outer wall of the aforementioned fleece tube 1 and at a position corresponding to the left end of the aforementioned air deflation tube 2 around the circumferential direction of the fleece tube 1, and on the A pre-deflation cavity sleeve 4 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com