Duvet and down filling method thereof

A duvet and quilt surface technology, applied in the field of down processing, can solve the problems of easy formation of down, time-consuming and labor-consuming down quilt, and achieve the effects of increasing service life, preventing down phenomenon, and filling down evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

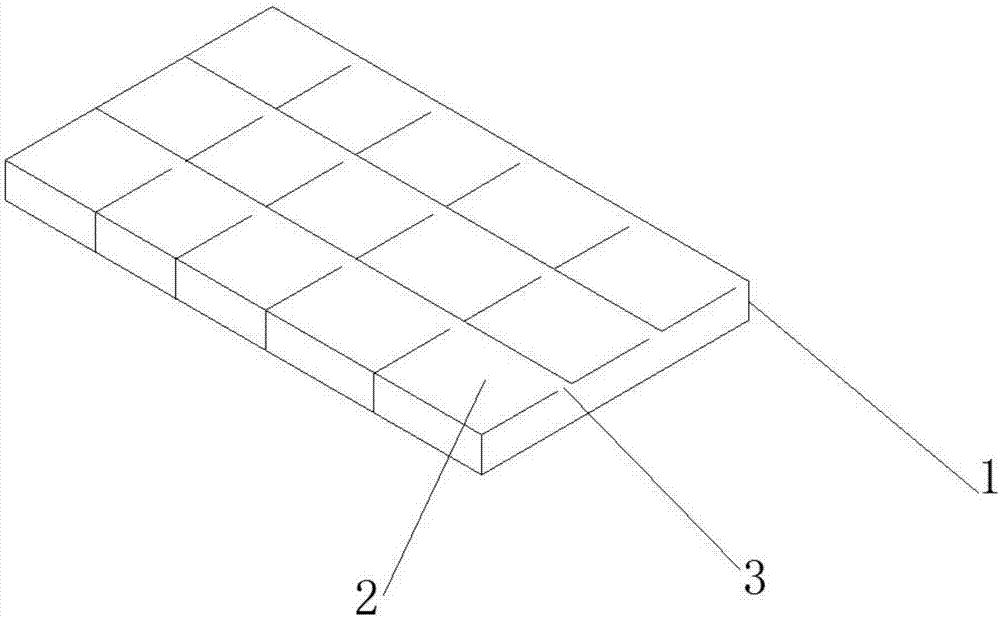

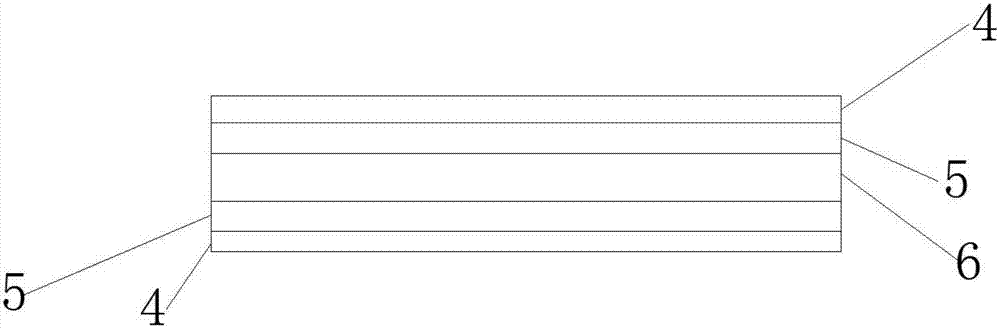

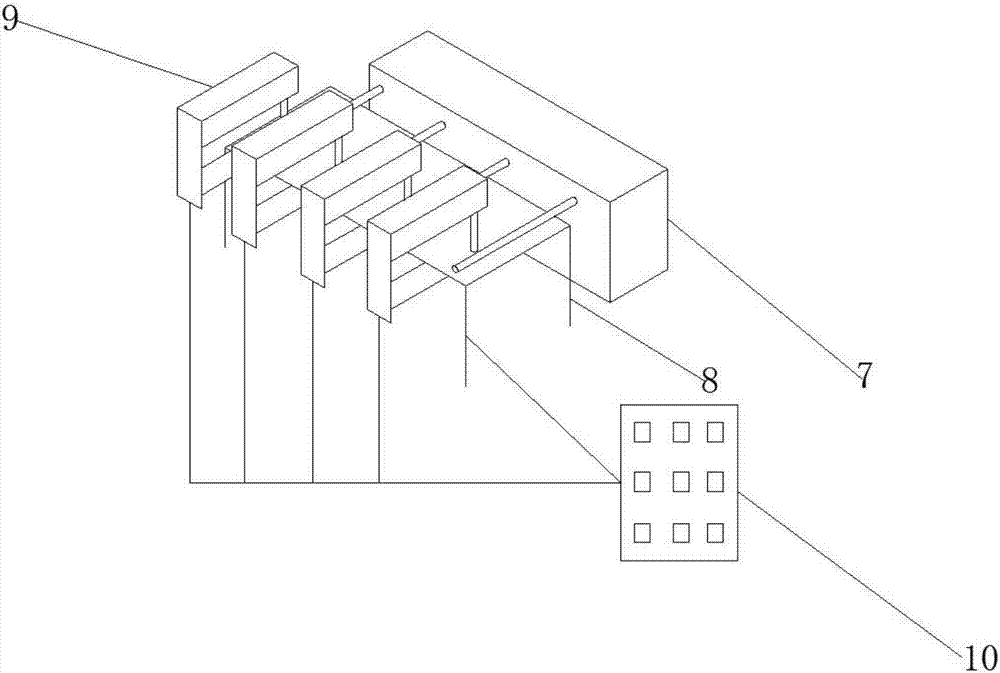

Embodiment 1

[0031] The wear-resistant layer of the outer layer of the quilt surface is made of nylon material, and the material of the fabric layer is made of cotton material. The four sides of the wear-resistant layer and the four sides of the fabric layer are bonded together by hot melt adhesive, and the quilt surface is folded symmetrically and passed through The four sides of the upper surface and the four sides of the lower surface are sewed together by the needle and thread, and a cavity is formed inside, and the cavity 6 is penetrated by the needle and thread from the upper surface of the quilt surface 1 to the lower surface to form a plurality of square cells 2, and the square cells 2 The end side is provided with a down filling port 3, and the square cells 2 are vertically connected through the down filling port 3, and the down filling port is filled with down through the down filling machine, and after the down filling is completed, the down filling port is sewn to form a duvet. ...

Embodiment 2

[0033] The wear-resistant layer of the outer layer of the quilt is made of polyester, the material of the fabric layer is made of cotton, and the remaining steps are the same as in Example 1.

Embodiment 3

[0035] The wear-resistant layer of the outer layer of the quilt is made of nylon, the material of the fabric layer is made of cotton, and the remaining steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com