Down filling machine

A cashmere filling machine and cashmere storage technology, which is applied in the field of cashmere filling machines, can solve the problems of high cashmere feeding pressure and large gaps between garment parts, and achieve the effects of easy operation, speeding up efficiency and reducing complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

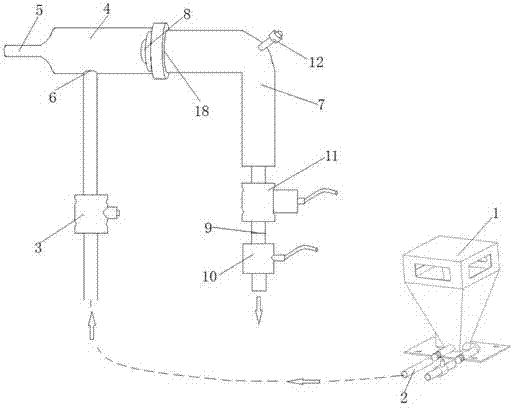

[0018] A down filling machine includes a down storage box and a weighing box 1. The down filled in the down storage box is transported to the weighing box 1 for weighing and then output through the down outlet 2 of the weighing box 1.

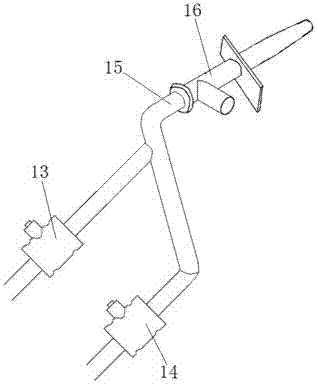

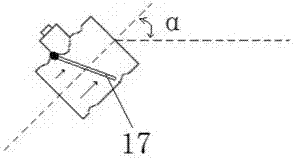

[0019] The down-filling machine also includes a down-out device, such as figure 2 As shown, the velvet outlet device includes a velvet storage chamber 4 , and one end of the velvet storage chamber 4 is a velvet outlet 5 . The other end of the velvet storage chamber 4 is provided with a trachea 7, and the first port 18 of the trachea 7 is connected with the velvet storage chamber 4 through a muffler 8, and the muffler 8 only allows the airflow in the velvet storage chamber 4 to flow to the trachea 7 or The airflow in the trachea 7 flows to the cashmere storage cavity 4 . The second port 9 of the trachea 7 is provided with an air suction device, where the air suction device adopts an air amplifier 10, the air inlet of the air amplifier 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com