Working method of down filling machine

A working method and down filling machine technology, which is applied in the optimization technology field of duvet filling machines, can solve problems such as unsatisfactory fit, low efficiency of down filling, uneven distribution of down, etc., and achieve fast speed and uniform distribution of down , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

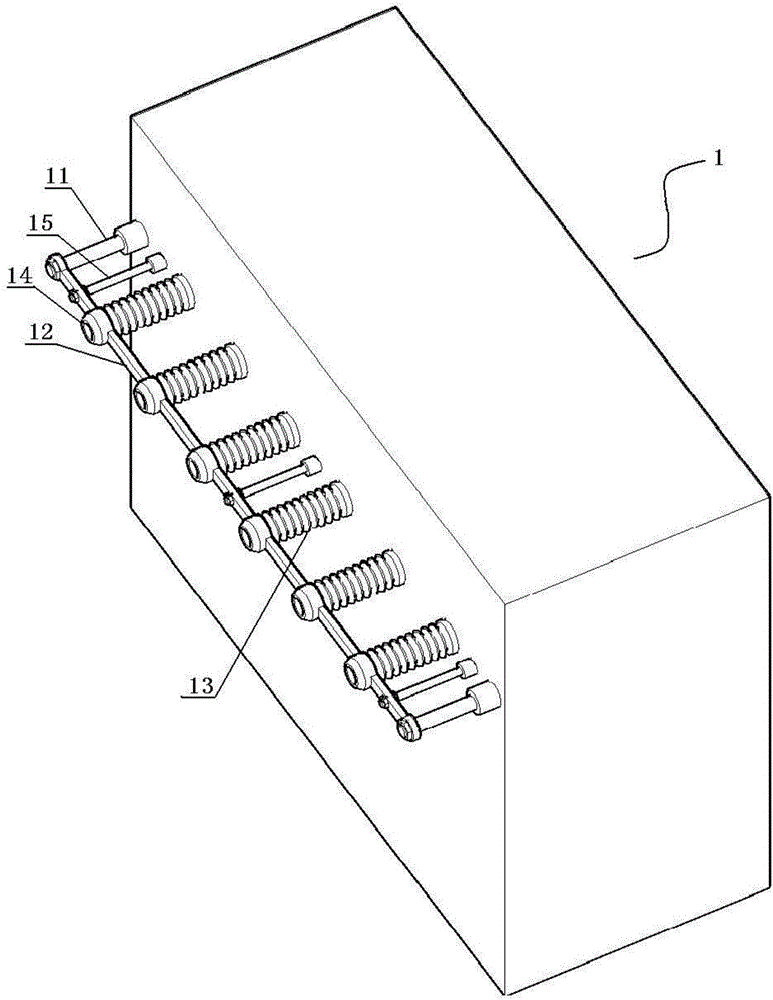

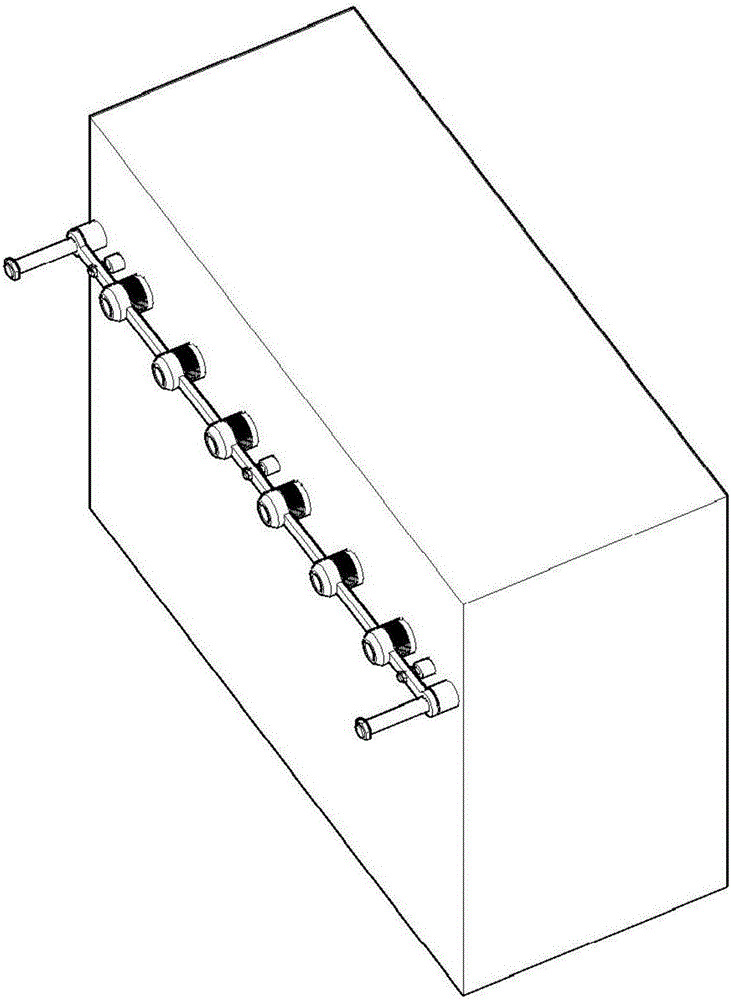

[0010] Such as figure 1 As shown, a working method of a down filling machine, a guide rod 11 is arranged on both sides of a wall of the down filling machine body, and a support frame 12 is arranged between the guide rods, and the support frame is under the action of an external force, Able to move axially along the guide rod.

[0011] The support frame is provided with a plurality of down-filled pipe joints, the two ends of the down-filled pipe joints are fixed on the support frame, and the down-filled pipe joints are provided with through holes parallel to the guide rods. In practical applications, each down-filling pipe joint corresponds to a down-filling pipe, and the number of down-filling pipes is usually the same as the number of horizontal or vertical grids of the duvet, so a row of grids can be filled with down at the same time. Since a row of grids can be filled with down at the same time, the number of horizontal and vertical grids of the duvet can be increased, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com