Down quilt down filling method

A technology for down quilt and quilt filling is applied in the field of optimization technology of down quilt filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

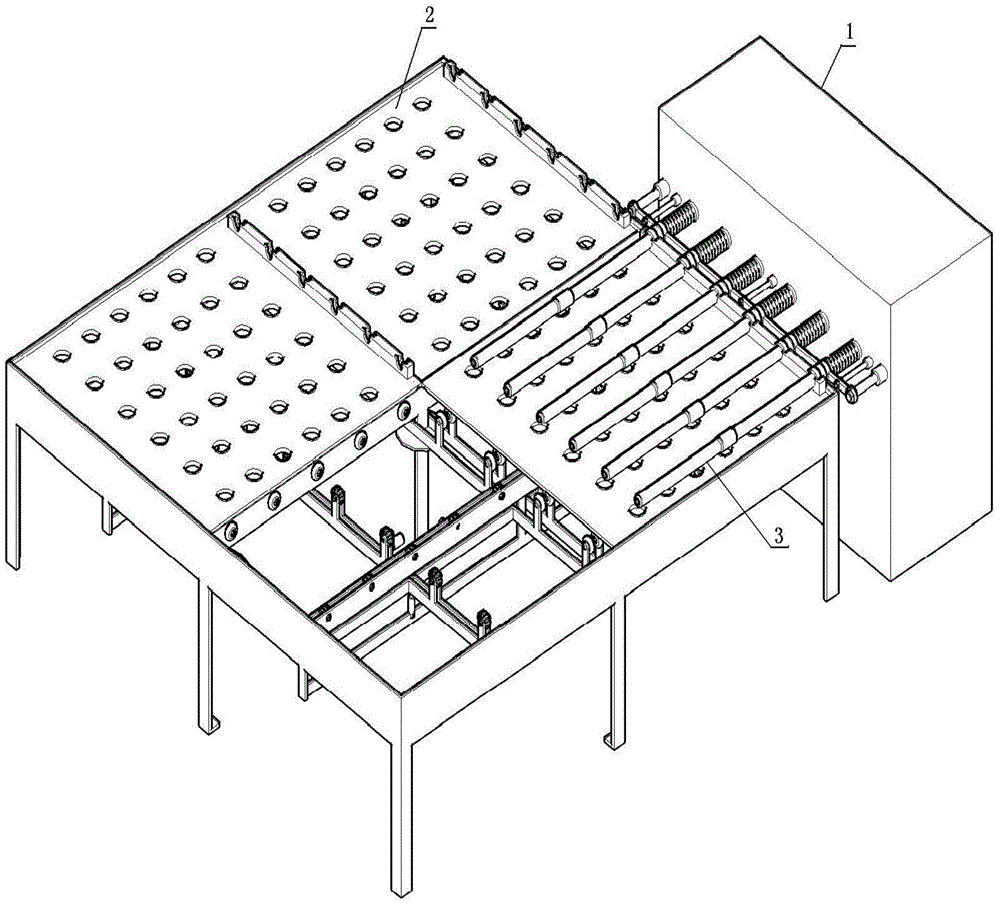

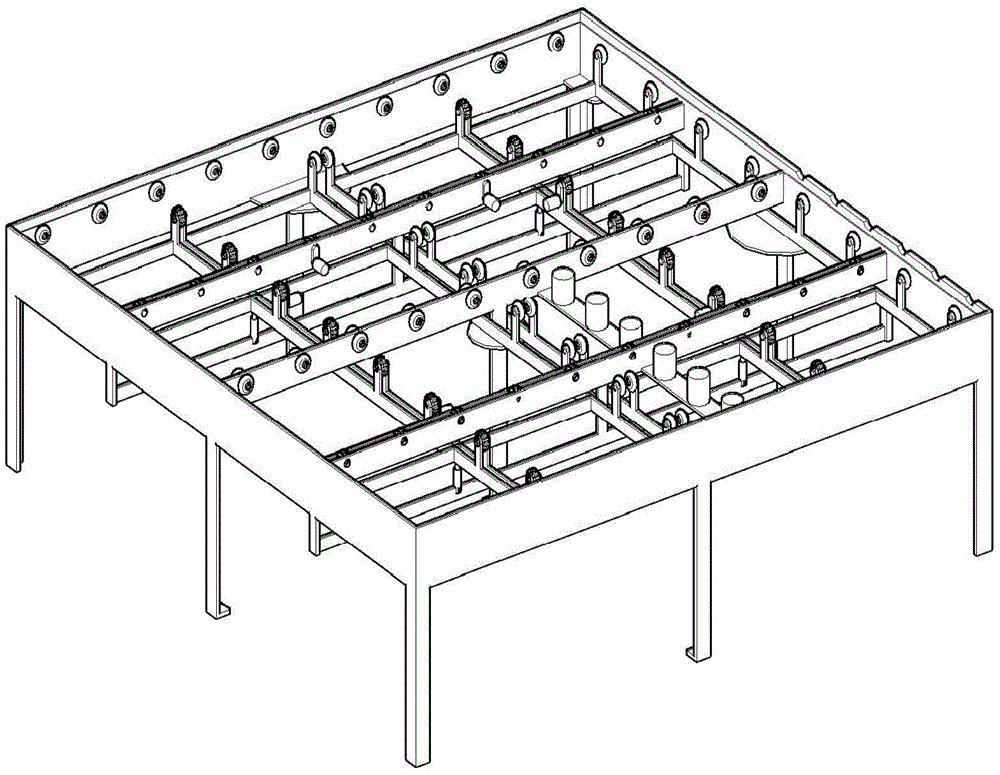

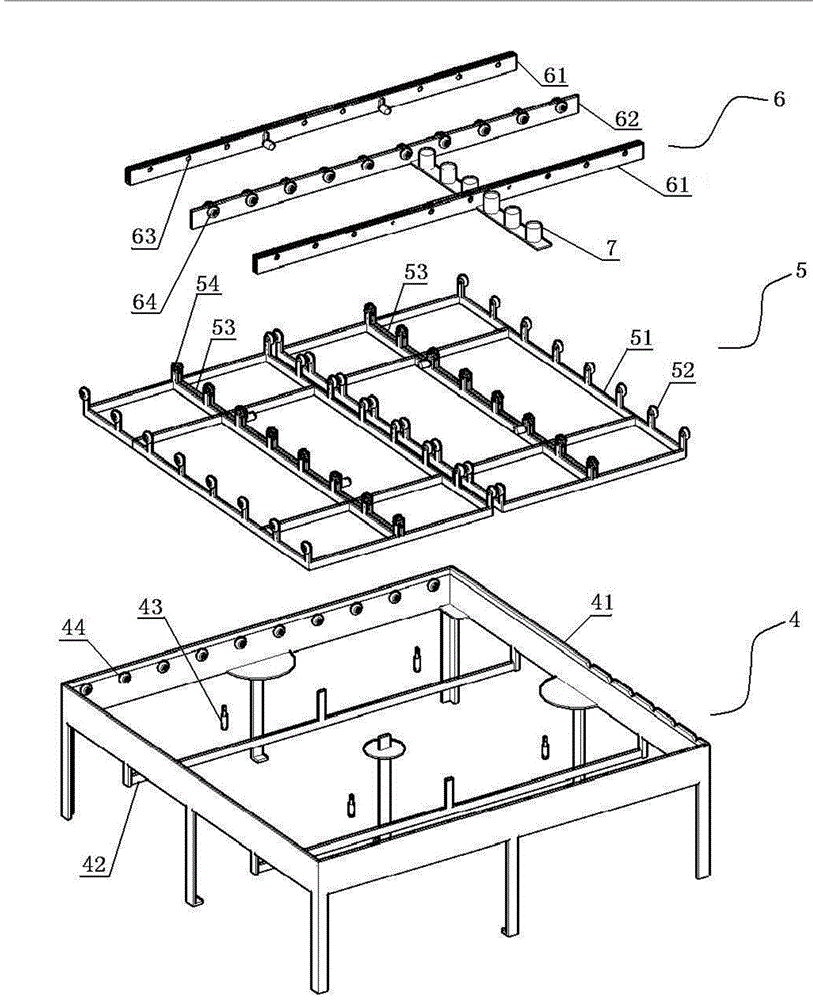

[0023] Such as figure 1 , figure 2 and image 3 As shown, a down filling method for a down quilt, the down filling equipment mainly consists of a down filling machine 1, a moving bed 2, a down filling pipe 3, a bed frame 4, a lateral moving frame 5, a longitudinal moving frame 6, an air suction fan 7, and a power unit It consists of a control system, the power unit is placed on the horizontal moving frame and the vertical moving frame, the down filling machine is placed on the side of the bed frame, and three flat moving beds 2 are placed on the bed frame, and the duvets that need to be filled are spread on the moving bed. The size of each moving bed is 1 / 4 of the inner hole of the bed frame; The lower bayonet; the bed frame area close to the down filling machine is the down filling area; the power unit includes a motor and a reducer; the control system uses a programmable industrial computer or computer chip or computer, and the mobile Driven by the power device, the bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com