Folding down filling pipe used on full-automatic down filling machine

A foldable and fully automatic technology, applied in the field of down filling equipment, can solve the problems of uneven filling and troublesome treatment of uniformity, and achieve the effect of reducing waste of down, improving uniformity and efficiency of filling down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

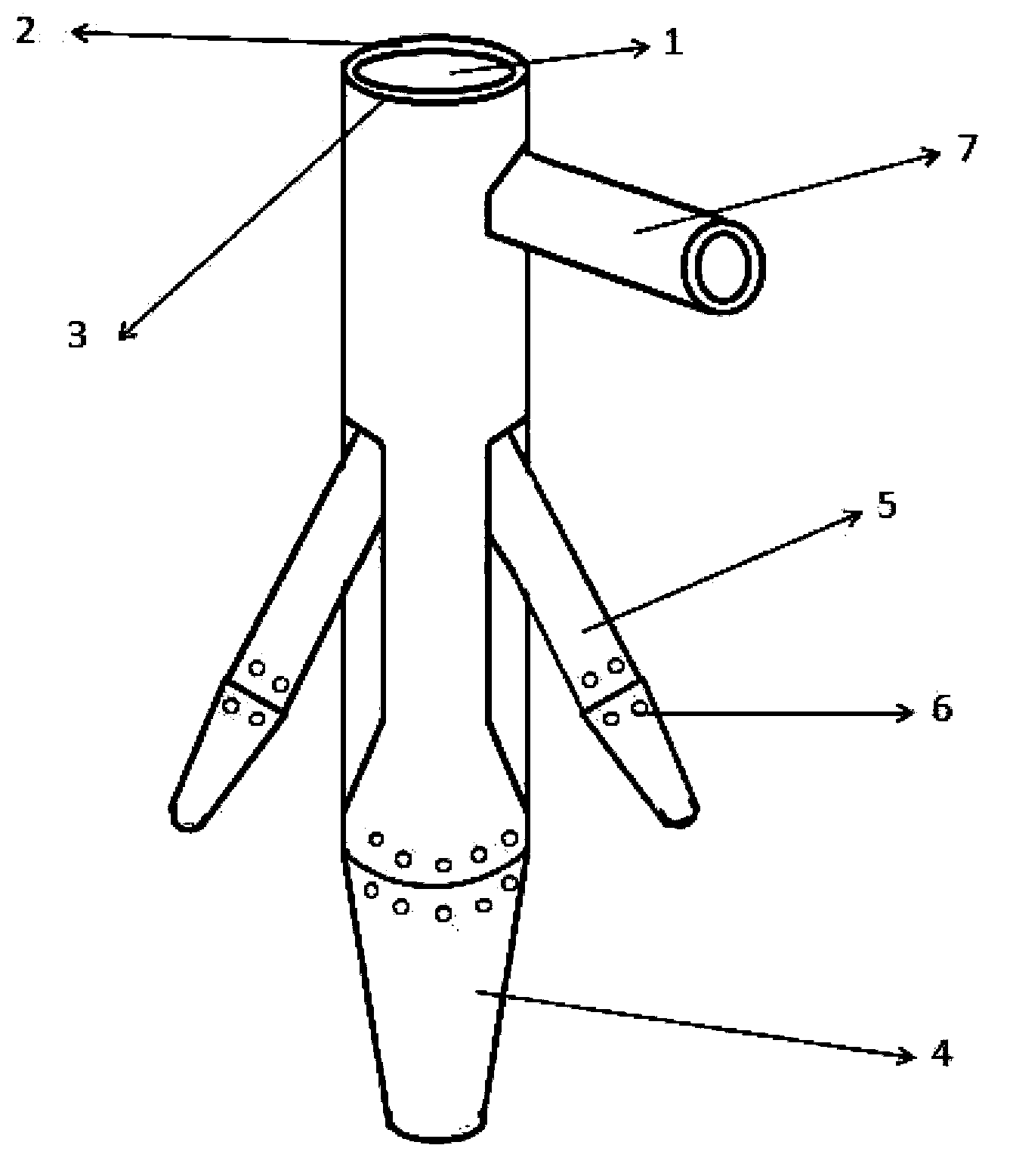

[0016] Such as figure 1 Shown, the present invention comprises main down filling tube 4, auxiliary down filling tube 5 and collection branch pipe 7, and auxiliary down filling tube 5 has two, is respectively positioned at the both sides of main down filling tube 4, and the root of auxiliary down filling tube 5 and The main down filling pipe 4 is fixed by the shaft, and the collecting branch pipe 7 is located at the rear end of the main down filling pipe 4;

[0017] Both the main down filling tube 4 and the auxiliary down filling tube 5 include an inner tube 1 and a casing 3, a gas return channel 2 is left between the inner tube 1 and the sleeve tube 3, and a gas return channel 2 is provided on the sleeve tube 3 to communicate with the return channel 2. Return air hole 6.

[0018] Both sides of the main down filling tube 4 are provided with spaces capable of accommodating the auxiliary down filling tube 5 , so that the auxiliary down filling tube 5 can be accommodated on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com