Pillow interior continuous production technology

A production process and technology of pillow core, applied in the field of continuous production process of pillow core, can solve the problems of pressing down and affecting the amount of down filling, etc., and achieve the effect of simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

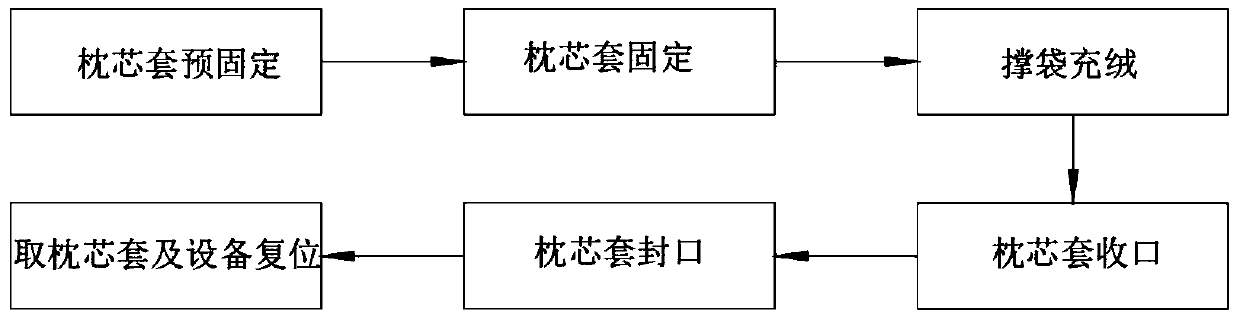

[0049] Such as figure 1 Shown, the present invention provides a kind of pillow core continuous production process, comprises the following steps:

[0050] Step 1: Pre-fix the pillow cover, manually place the pillow cover in the clamping station formed by a pair of fixing components 32, and then, the cylinder a335 drives the pair of fixing components 32 to move closer to the middle to initially place the pillow cover Clamp;

[0051]Step 2: The pillow cover is fixed. After step 1, the transport component 31 drives the fixed component 32 and the pillow cover to move, and the splint 325 moves along the upper surface of the limiting plate a326, and the splint 325 gradually moves up to make the pillow cover Fold it outwards and clamp the pillowcase tightly;

[0052] Step 3: Stretch the bag and fill it with cashmere. After step 2, the pillow cover is transferred to the bottom of the cotton filling device 4, and the cylinder b336 works to make the pair of fixing components 32 move o...

Embodiment 2

[0066] The present invention also provides a pillow core continuous production equipment:

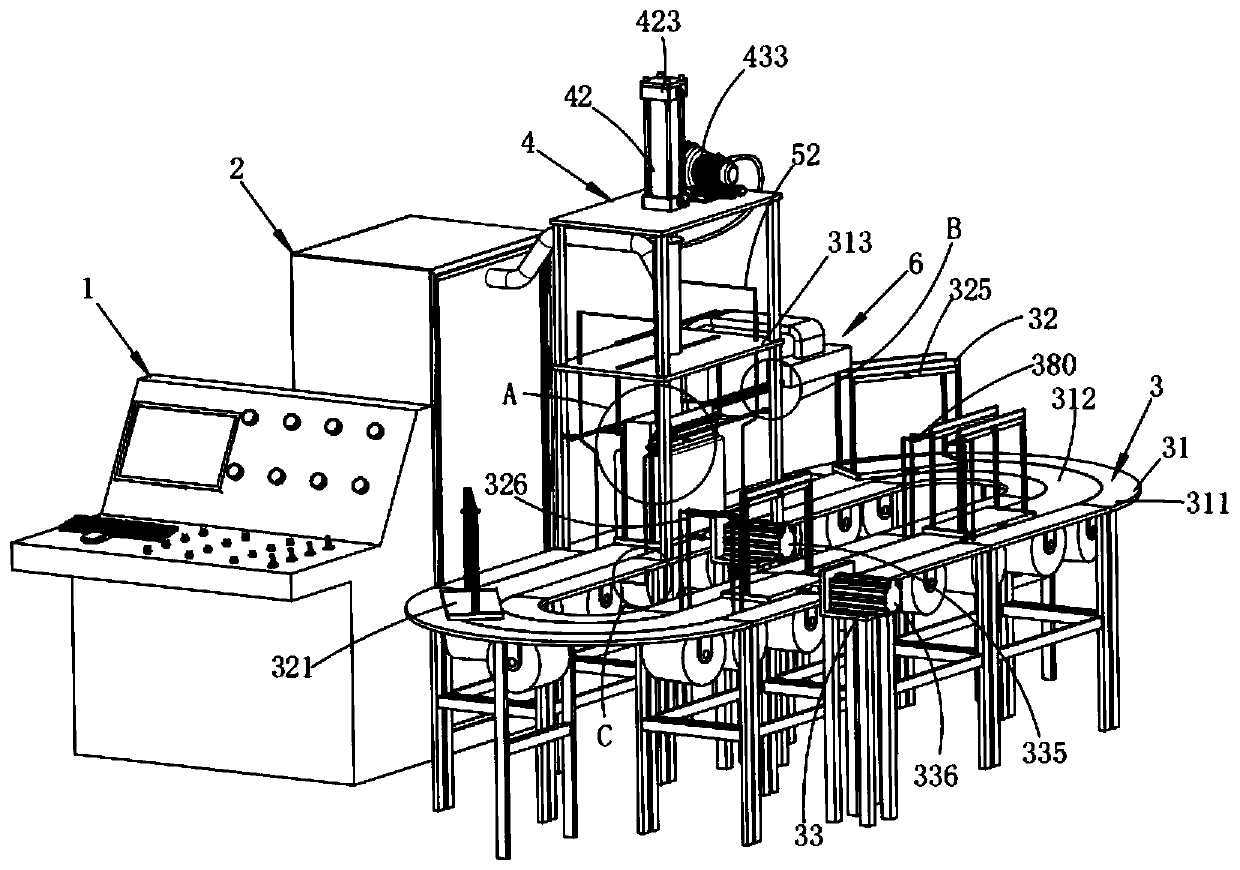

[0067] Such as figure 2 and Figure 12 As shown, a continuous production equipment for pillow cores includes a console 1 and a filling machine 2, and also includes:

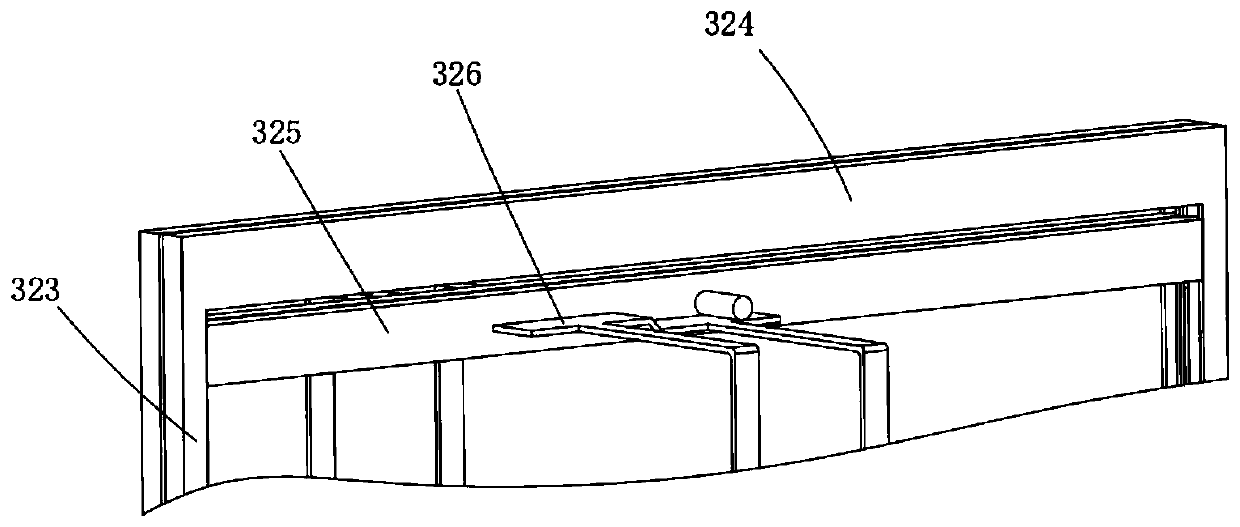

[0068] The bag supporting device 3, the bag supporting device 3 includes a transport assembly 31, a fixed assembly 32 and a position limiting assembly 33, and a plurality of bases 321 are arrayed on the transport assembly 31; The long sides are arranged correspondingly, and the fixing assembly 32 is slidably arranged along the conveying direction perpendicular to the transportation assembly 31. The fixing assembly 32 includes a splint 325 and a limit plate a326, and the splint 325 is slidably arranged on the fixing assembly 32 up and down. The upper part of the limit plate a326 is fixedly installed on the transport assembly 31, and the height of the limit plate a326 increases along the moving direction of the transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com