Enzyme microbial organic fertilizer and preparation method thereof

A bio-organic fertilizer and enzyme technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve the problems of lack of crop protein and trace elements, short shelf life of starch and water-retaining agents, and insufficient organic and inorganic nutrients. , to achieve the effect of solving serious harm, overcoming serious damage and vicious circle, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] A preparation method of ferment bio-organic fertilizer, comprising the steps of:

[0063] a. Weigh chicken manure, pig manure, protein powder, tung tree, peat, straw powder, enzyme expansion bacteria, rice bran and brown sugar respectively according to the proportion, then add 45% of the total amount of water and mix evenly to adjust the pH value To 6, open aerobic fermentation process mixed materials;

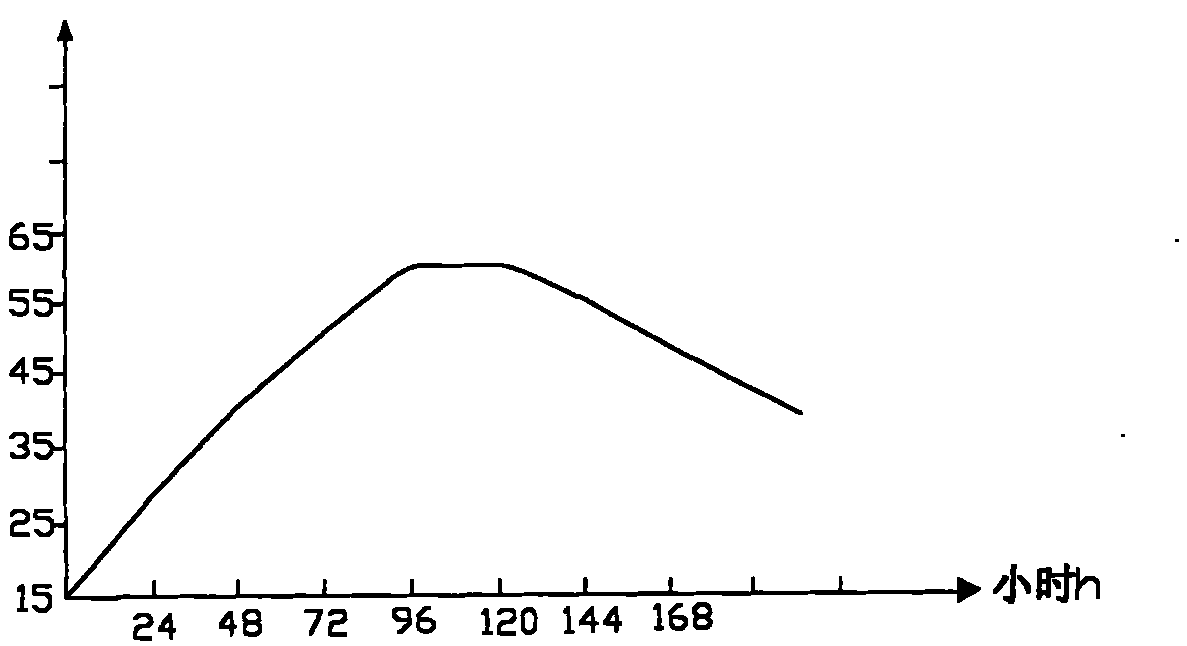

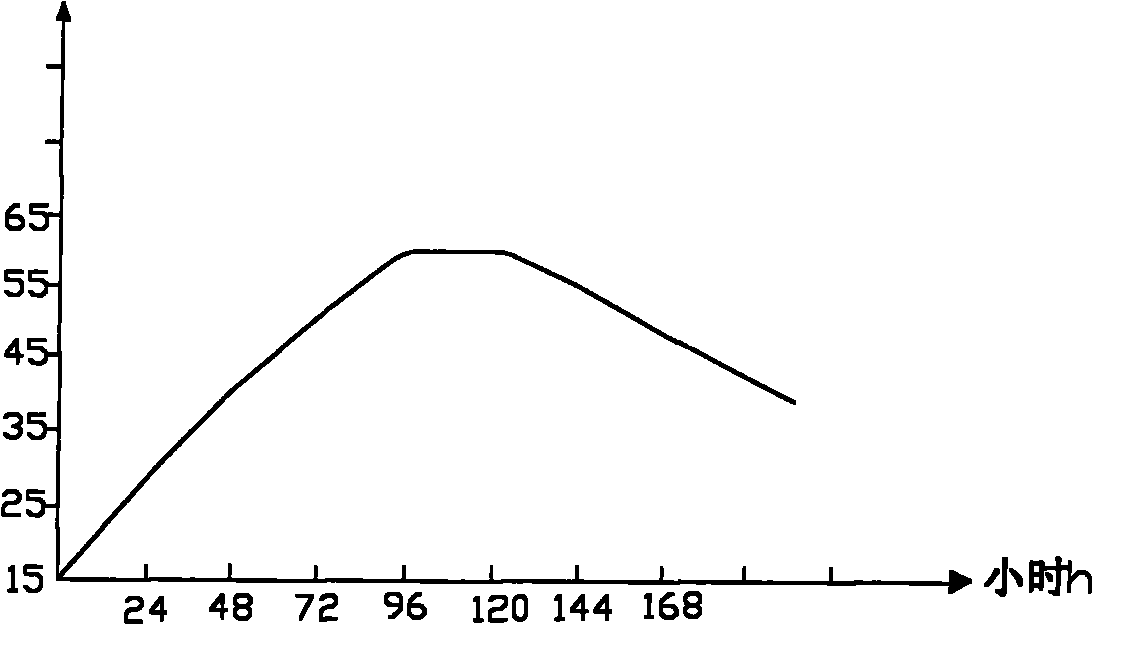

[0064] b. Aerobic fermentation treatment for 48 hours, evenly adding monoammonium phosphate to the material, crushing the material, and turning the material for the first time at the same time;

[0065] c. Aerobic fermentation treatment for 96 hours, uniformly add urea in the material, and turn the material for the second time;

[0066] d. After 144 hours of aerobic fermentation treatment, the material is turned over for the third time;

[0067] e, aerobic fermentation treatment for 168 hours, stop the fermentation, make the moisture content in the material <25%, and ...

Embodiment 2

[0076] A kind of ferment biological organic fertilizer, comprises the formula of following components:

[0077] 40 tons of chicken manure,

[0078] 14 tons of pig manure,

[0079] protein powder 5 tons,

[0080] Tongku 5 tons,

[0081] Peat 10 tons,

[0082] Straw powder 15 tons,

[0083] 3 tons of urea,

[0084] Monoammonium phosphate 5 tons,

[0085] Potassium sulfate 2 tons,

[0086] Enzyme expansion bacteria 1 ton,

[0087] 0.2 tons of rice bran,

[0088] Brown sugar 0.2 tons,

[0089] Trace elements 0.1 tons.

[0090] A preparation method of ferment bio-organic fertilizer, comprising the steps of:

[0091] a. Weigh the chicken manure, pig manure, protein powder, tung tree, peat, straw powder, enzyme expansion bacteria, rice bran and brown sugar respectively according to the proportion, then add water accounting for 50% of the total formula and mix evenly to adjust the pH value To 7.5, open aerobic fermentation process mixed materials;

[0092] b. Aerobic ferm...

Embodiment 3

[0099] A ferment bio-organic fertilizer is characterized in that it comprises the formula of the following components:

[0100] 40 tons of chicken manure,

[0101] 14 tons of pig manure,

[0102] protein powder 5 tons,

[0103] Tongku 5 tons,

[0104] Peat 10 tons,

[0105] Straw powder 15 tons,

[0106] 3 tons of urea,

[0107] Monoammonium phosphate 5 tons,

[0108] Potassium sulfate 2 tons,

[0109] Enzyme expansion bacteria 1 ton,

[0110] 0.2 tons of rice bran,

[0111] Brown sugar 0.2 tons,

[0112] Trace elements 0.1 tons.

[0113] A preparation method of ferment bio-organic fertilizer, comprising the steps of:

[0114] a. Weigh the chicken manure, pig manure, protein powder, paulownia, peat, straw powder, enzyme expansion bacteria, rice bran and brown sugar respectively according to the proportion, then add water accounting for 47% of the total formula and mix evenly to adjust the pH value To 7, the open aerobic fermentation process mixed materials;

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com