Method and system for co-processing waste incineration fly ash and zinc-containing dust mud of steel plant

A waste incineration fly ash and co-processing technology, applied in the direction of furnace, furnace type, rotary drum furnace, etc., can solve the problems of increasing the final processing capacity, low strength of solidified body, failure to achieve volume reduction and resource utilization, and achieve solidification Good effect, good resource utilization effect, good vitrified structure and hydration activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

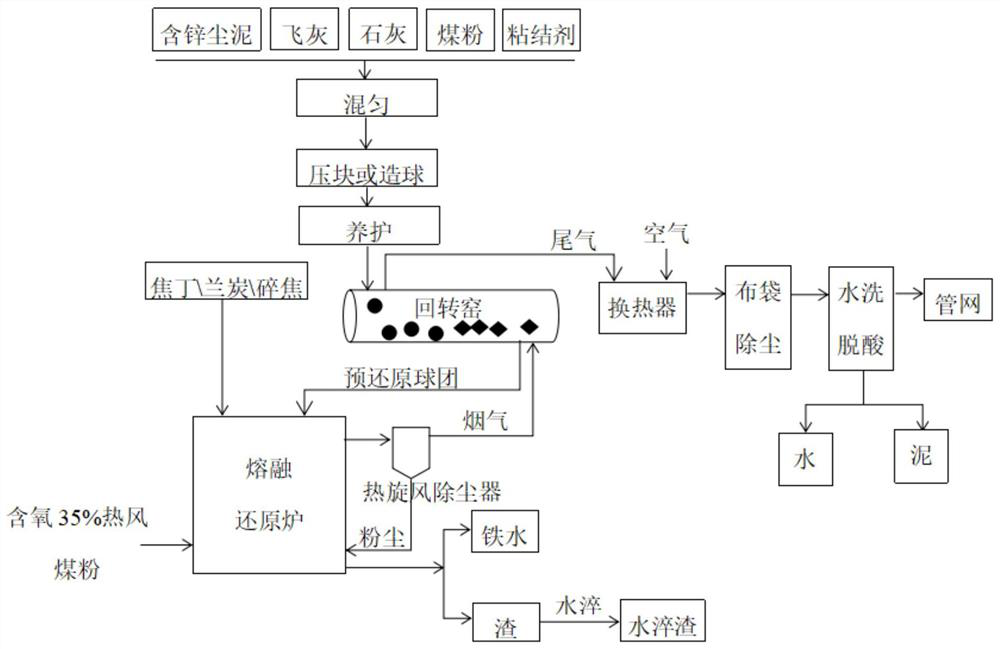

Method used

Image

Examples

Embodiment 1

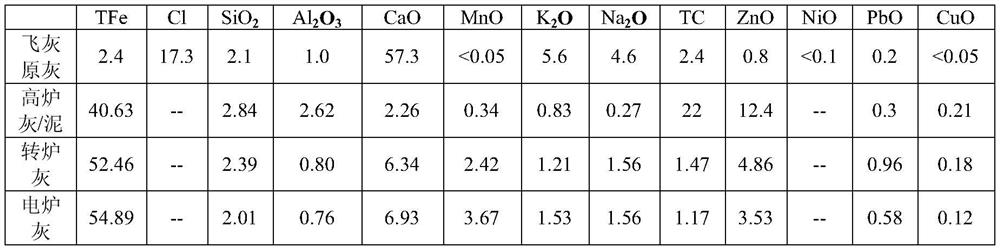

[0058]Premix the fly ash and blast furnace zinc-containing ash / mud at a ratio of 1:9, add 2% binder, 1.5% lime, and 8-10% water according to the mass ratio for mixing, and then briquetting on the roller forming machine. Then natural conservation for 72h. Afterwards, it is continuously fed into the rotary kiln for pre-reduction, and the obtained hot charge is discharged into the smelting reduction furnace by a screw conveyor. Mix coke, semi-coke, and crushed coke foam in proportion and add them to the silo, and feed them into the smelting reduction furnace from the top of the furnace through the material tank in batches. Hot air at 1250°C with an oxygen concentration of 30% is blasted into the hearth tuyeres of the smelting reduction furnace, and pulverized coal is sprayed into the tuyeres. The crude gas at about 830°C discharged from the smelting reduction furnace is separated from the carbon-containing coarse dust by the hot cyclone dust collector, and then enters the rotary...

Embodiment 2

[0060] Premix fly ash and zinc-containing dust (blast furnace ash and converter ash in a ratio of 1:2) in a ratio of 1.5:8.5. According to the mass ratio, the amount of carbon is 3%, binder 2.5%, lime 1.5%, moisture Controlled at 8-10%, the working procedure is the same as above. Among them, the blast temperature of the smelting reduction furnace is 1220°C, the oxygen concentration is 35%, and the blast humidity is 9g / m 3 , the amount of coal injection is 180kg / t. The gas temperature at the inlet of the rotary kiln is 810°C.

Embodiment 3

[0062] Premix fly ash and zinc-containing dust sludge (blast furnace ash, converter ash and electric furnace ash three kinds of zinc-containing dust in a ratio of 1:1:1) in a ratio of 2:8, with a carbon content of 7% according to the mass ratio, and bond Addition of agent is 3%, lime 1.5%, and operation process is the same as above. Among them, the blast temperature of the smelting reduction furnace is 1200°C, the oxygen concentration is 35%, and the blast humidity is 12g / m 3 , the amount of coal injection is 170kg / t. The gas temperature at the inlet of the rotary kiln is 800°C.

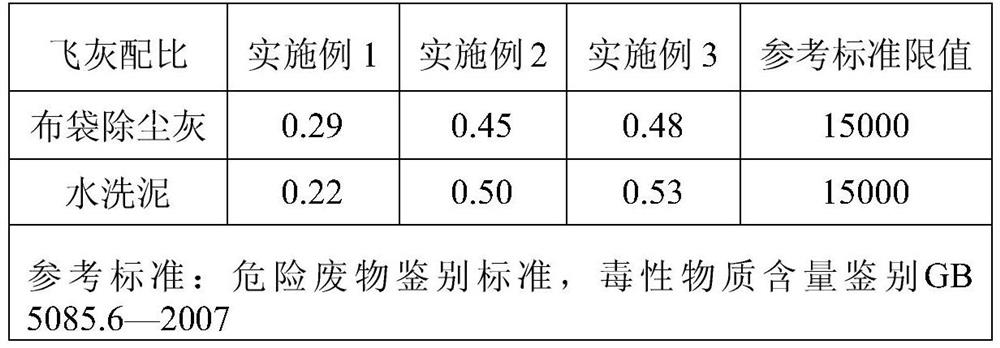

[0063] The above-mentioned 3 examples, after detection and analysis, as shown in Table 2 to Table 6 below, the concentration of dioxin in bag dust removal ash, clean gas, and water washing mud is far lower than the environmental protection discharge standard value; the Cl ion content of water slag is all <0.06% , The leaching concentrations of various heavy metals in water slag, bag dust and washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com