Rubber plastic ventilation (muffling) hose

A technology of rubber and plastic pipes and hoses, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of carcinogenicity, etc., and achieve the effects of small ventilation resistance, high installation efficiency, and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

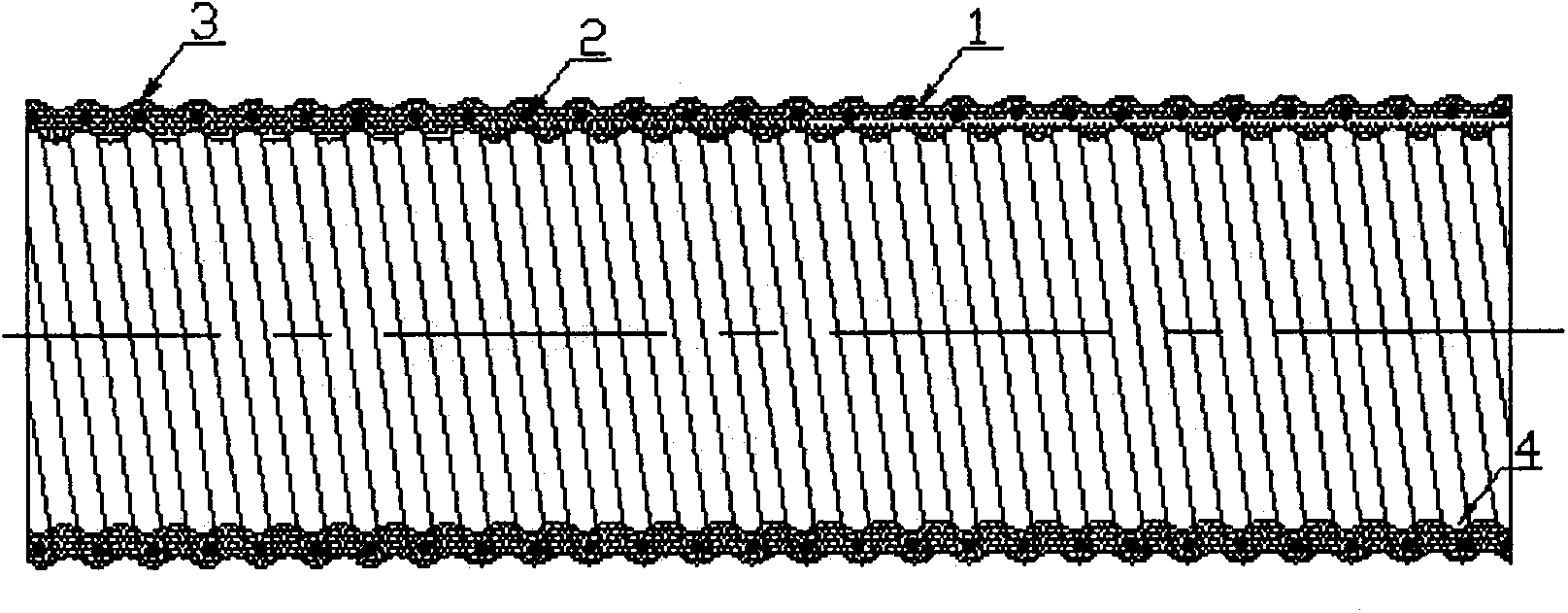

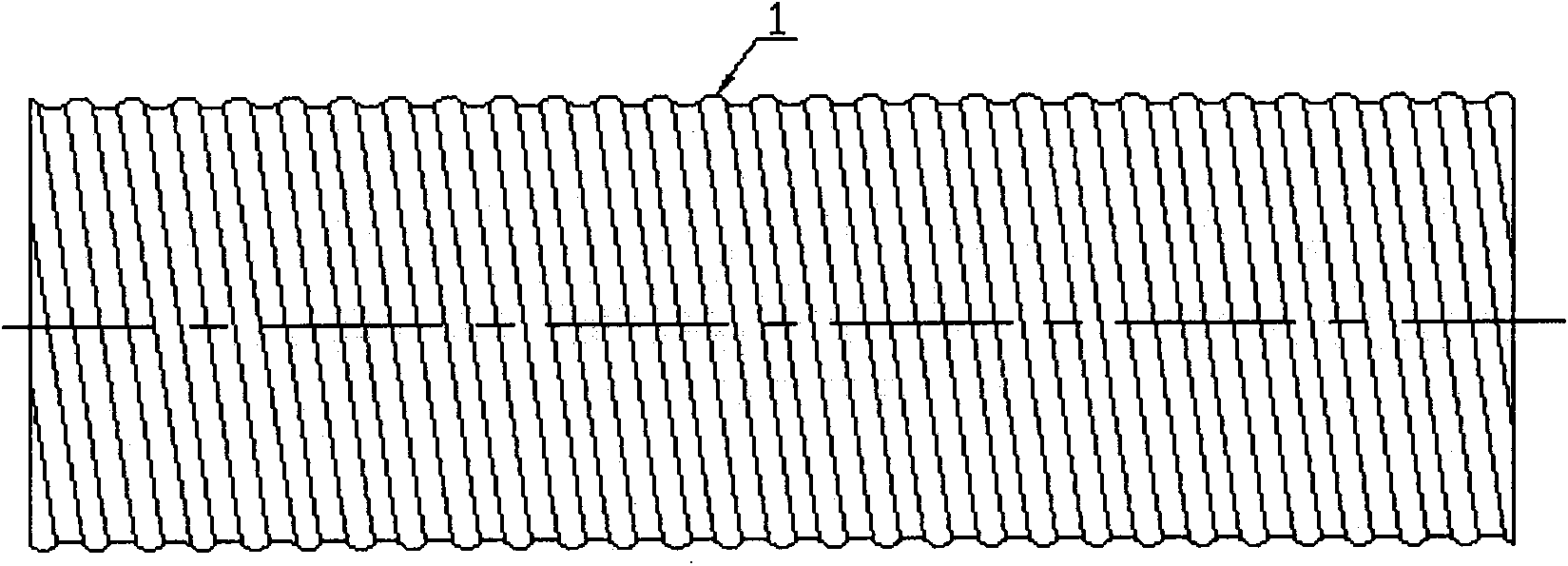

[0017] Embodiment 1, a rubber-plastic ventilation (muffling) hose, a helical spring steel wire is built in the middle of the rubber-plastic flexible hose, and the spring steel wire supports the rubber-plastic pipe wall and integrates with the pipe wall to expand or bend together.

[0018] In the process of gas delivery, the gas passes through the middle of this rubber and plastic ventilation (muffling) hose, and the airflow generated by it passes through the spiral structure of the inner pipe wall to generate a rotating airflow, and the vibration and noise generated by it are absorbed by the flexible elastic pipe wall , The rotating airflow reduces the resistance of the gas and accelerates the passage of the airflow, so that the gas can be transported to the end smoothly, fully meeting the requirements of the ventilation hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com