Method for measuring zinc and nickel contents in zinc-nickel alloy electroplating solution

A measurement method, the technology of zinc-nickel alloy, is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by making materials undergo chemical reactions, which can solve the impact on human health and the environment, the large error of measurement results, the solution End-point discoloration and insensitivity problems, to achieve the effect of quality assurance, accurate and consistent test results, and convenient testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below with regard to specific embodiments.

[0049] A kind of assay method of zinc-nickel content of zinc-nickel alloy electroplating solution, it comprises the following steps:

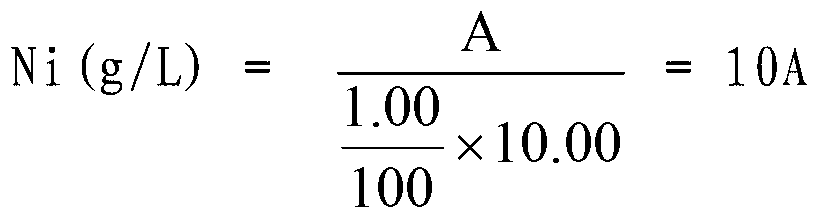

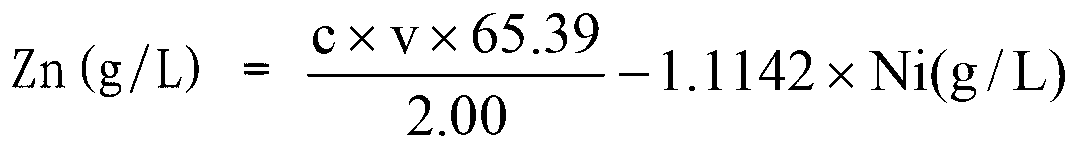

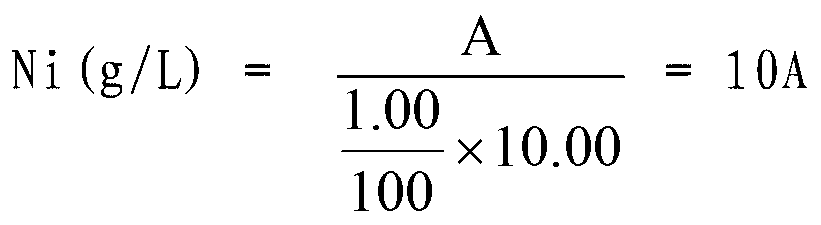

[0050] 1. Determination of nickel content

[0051] 1. Preparation of blank solution

[0052] a. Take 1.00mL of the electroplating solution to be tested, place it in a 100mL volumetric flask, add water to dilute to the mark, and shake well;

[0053] b. Draw 10.00mL of the diluted plating solution and place it in a 100mL volumetric flask, then add 10mL of sodium tartrate solution with a concentration of 200g / L, 10mL of sodium hydroxide solution with a concentration of 100g / L, and 5mL of sodium hydroxide solution with a concentration of 5mL into the volumetric flask. Ammonium persulfate solution of 100g / L;

[0054] c. Add water to dilute to the mark, shake well and set aside.

[0055] 2. Draw the working curve

[0056] a. Add 0.00mL, 0.50mL, 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com