Method for preparing fired bricks by using andalusite, sillimanite and feldspar quarry wastes as raw materials

A technology of sillimanite and andalusite, applied to the removal of solid waste, etc., can solve the problems of occupying cultivated land, rivers, accumulation and occupation of cultivated land, hazards, etc., and achieve the effect of saving cultivated land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

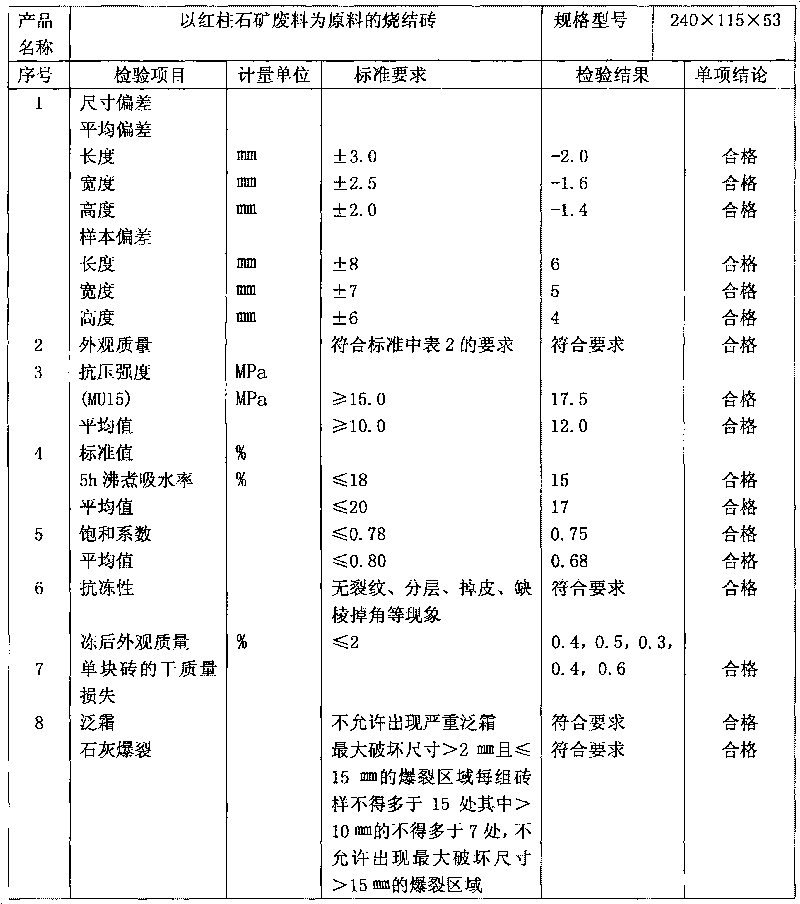

[0011] The present invention uses any one or waste of two or more ores of andalusite, sillimanite, and feldspar as raw materials to prepare sintered bricks. Raw material formula 1 uses the following raw materials in weight percentages: andalusite, sillimanite, and feldspar Mine waste ore 20%, andalusite, sillimanite, feldspar mine tailings powder 75%, andalusite, sillimanite, feldspar mine stripping layer 5%.

[0012] The present invention uses any one or waste of two or more ores of andalusite, sillimanite, and feldspar as raw materials to prepare sintered bricks. The raw material formula 2 of the embodiment adopts the following weight percentage raw materials: andalusite, sillimanite, and feldspar Mine waste ore 80%, andalusite, sillimanite, feldspar mine tailings powder 10%, andalusite, sillimanite, feldspar mine stripping layer 10%.

[0013] The present invention uses any one or waste of two or more ores of andalusite, sillimanite, and feldspar as raw materials to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com