Making method of acid-proof polyamide fabric

A nylon and acid-proof technology is applied in the field of preparation of acid-proof nylon fabrics, which can solve the problems of environmental and human health hazards, contact with human body, and fabric damage, and achieve the effects of reducing damage, increasing fastness, and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

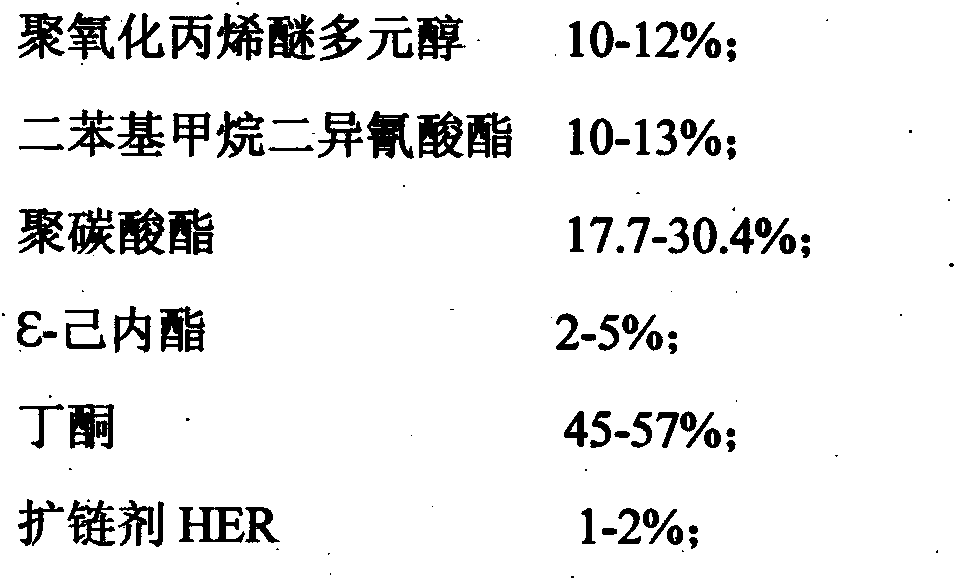

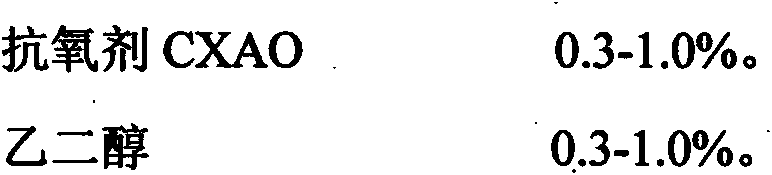

[0023] The special acid-resistant polyurethane resin for nylon fabric described in this embodiment is formulated by weight percentage from the following components:

[0024]

[0025]

[0026] The preparation method of acid-proof polyamide fiber hook and loop comprises the steps:

[0027] 1. First add polyoxypropylene ether polyol, diphenylmethane diisocyanate, polycarbonate (5%), ε-caprolactone, methyl ethyl ketone, chain extender HER and antioxidant in proportion to the reaction kettle Agent CXAO, reacted at 70°C for 1 hour to make an anti-acid finishing agent, add the remaining polycarbonate to the anti-acid finishing agent in a proportion of 25.3% by weight to increase viscosity, when the solid content reaches 50%, that is When the sum of polyoxypropylene ether polyol, diphenylmethane diisocyanate, polycarbonate and ε-caprolactone reaches 50%, it is blocked with an end-capping agent ethylene glycol to obtain an acid-resistant polyurethane resin;

[0028] 2. Fully mix...

Embodiment 2

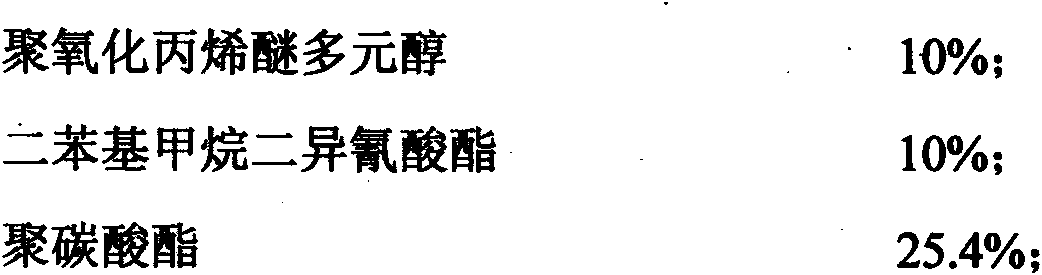

[0034] The special acid-resistant polyurethane resin for nylon fabric described in this embodiment is formulated by weight percentage from the following components:

[0035]

[0036] The preparation method of acid-proof nylon fabric comprises the steps:

[0037] 1. First add polyoxypropylene ether polyol, diphenylmethane diisocyanate, polycarbonate (8%), ε-caprolactone, methyl ethyl ketone, chain extender HER and antioxidant CXAO into the reaction kettle , After reacting at 75°C for 1.5 hours, add the remaining polycarbonate to increase viscosity, when the solid content reaches 50%, that is, polyoxypropylene ether polyol, diphenylmethane diisocyanate, polycarbonate and ε-hexyl When the sum of the esters reaches 50%, it is blocked with an end-blocking agent ethylene glycol to obtain an acid-resistant polyurethane resin.

[0038] 2. Fully mix the acid-resistant polyurethane resin, butanone and cross-linking agent at 45°C to make an acid-resistant reinforcing adhesive. The we...

Embodiment 3

[0044] The special acid-resistant polyurethane resin for nylon fabric described in this embodiment is formulated by weight percentage from the following components:

[0045]

[0046] The preparation method of acid-proof nylon fabric comprises the steps:

[0047] 1. First add polyoxypropylene ether polyol, diphenylmethane diisocyanate, polycarbonate (add 10%), ε-caprolactone, butanone, chain extender HER and antioxidant CXAO to the reaction kettle , after reacting at 80°C for 1.5 hours, add the remaining polycarbonate to increase viscosity, when the solid content reaches 50%, that is, polyoxypropylene ether polyol, diphenylmethane diisocyanate, polycarbonate and ε-hexyl When the sum of the esters reaches 50%, it is blocked with an end-blocking agent ethylene glycol to obtain an acid-resistant polyurethane resin.

[0048] 2. Fully mix the acid-resistant polyurethane resin, butanone and cross-linking agent at 50°C to make an acid-resistant reinforcing adhesive. The weight rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com