Patents

Literature

32results about How to "Increase the rate of the hydrogenation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

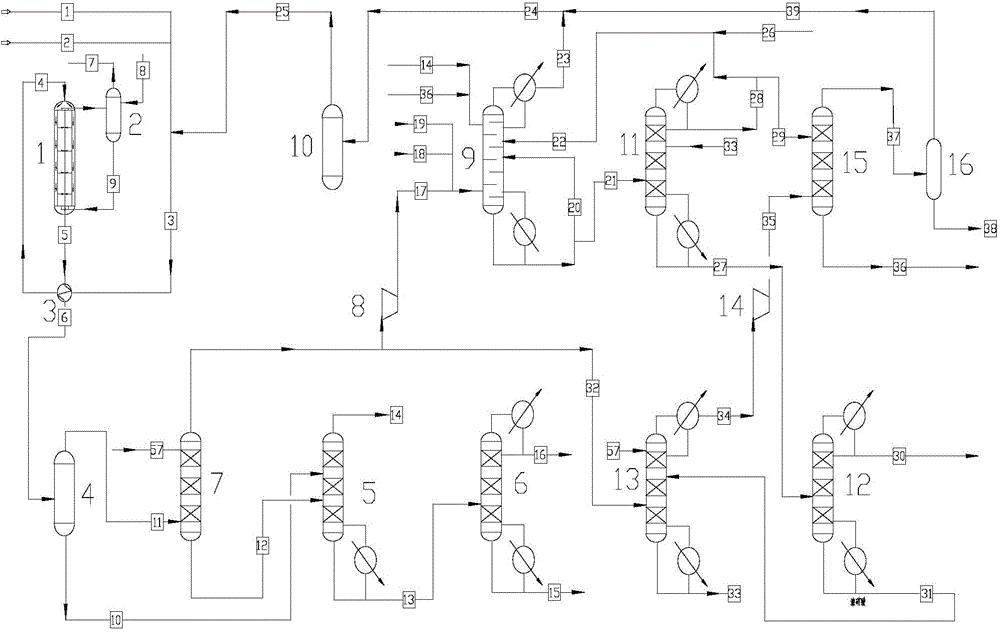

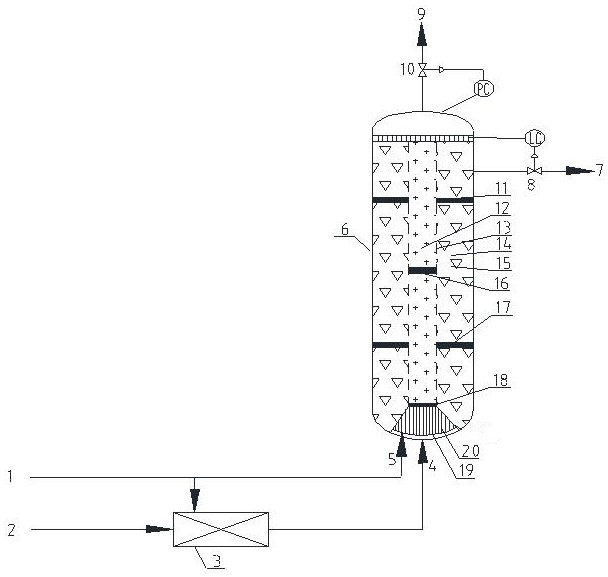

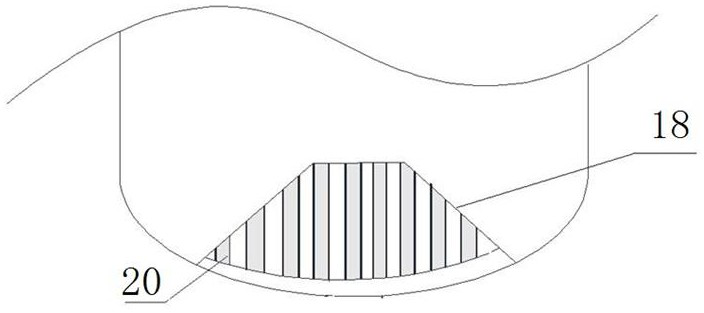

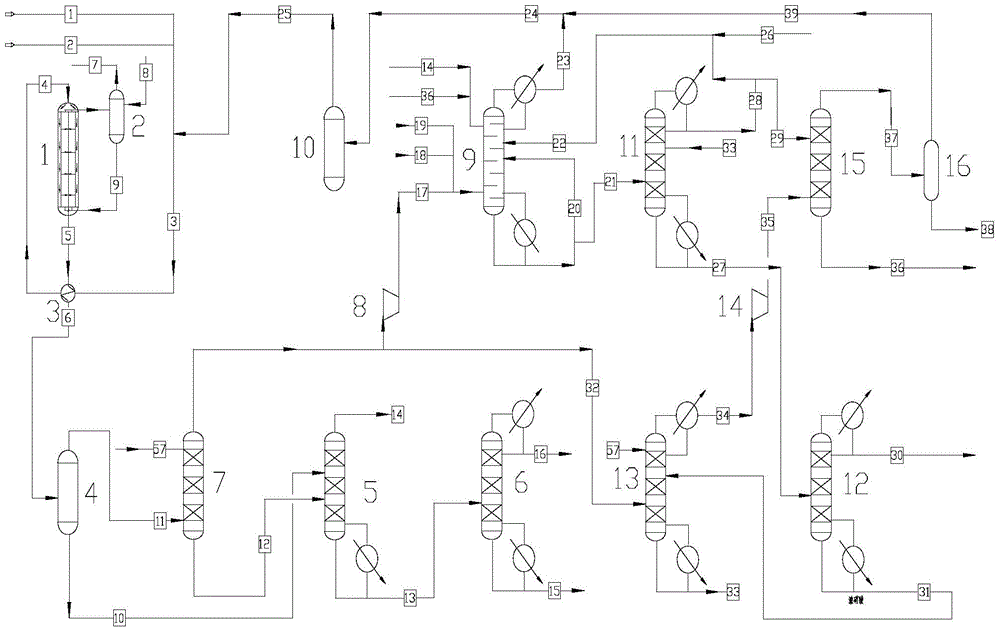

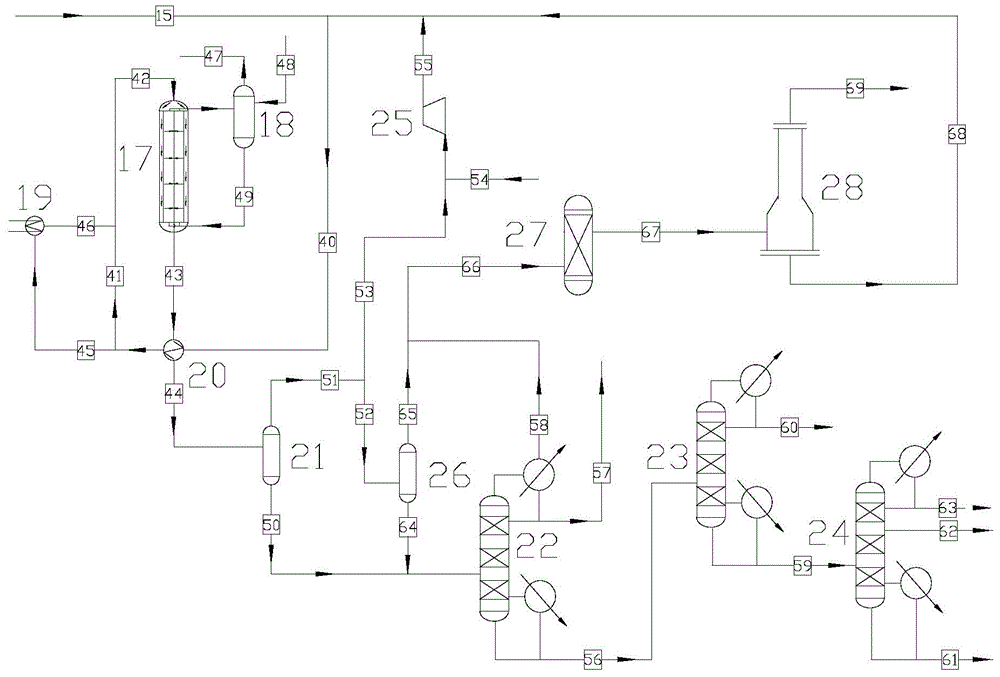

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

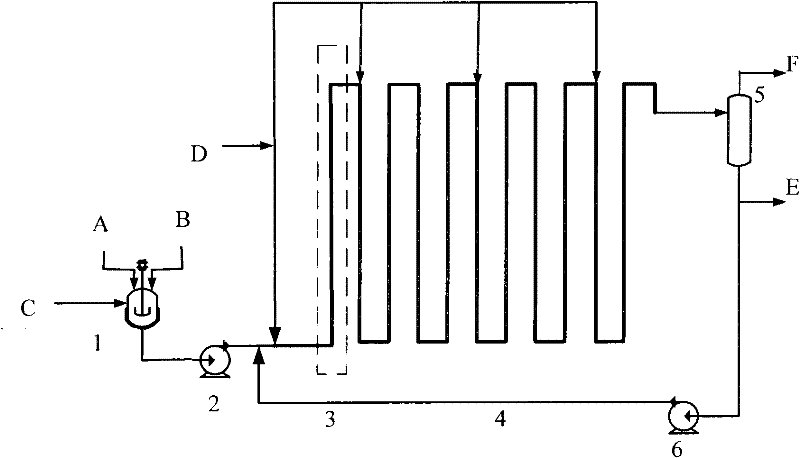

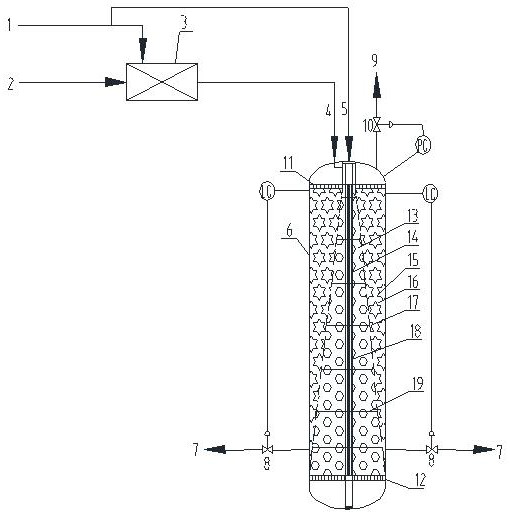

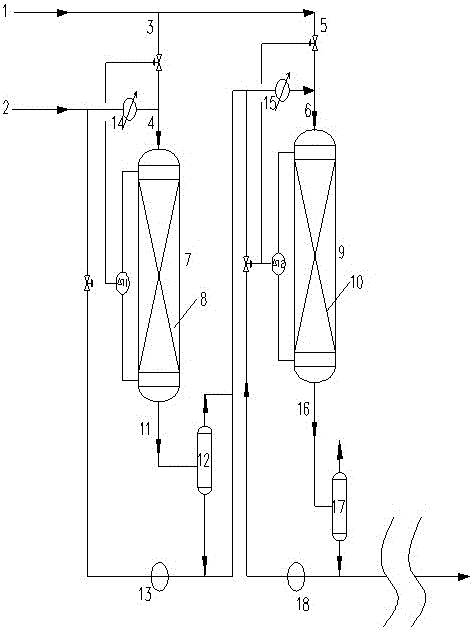

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

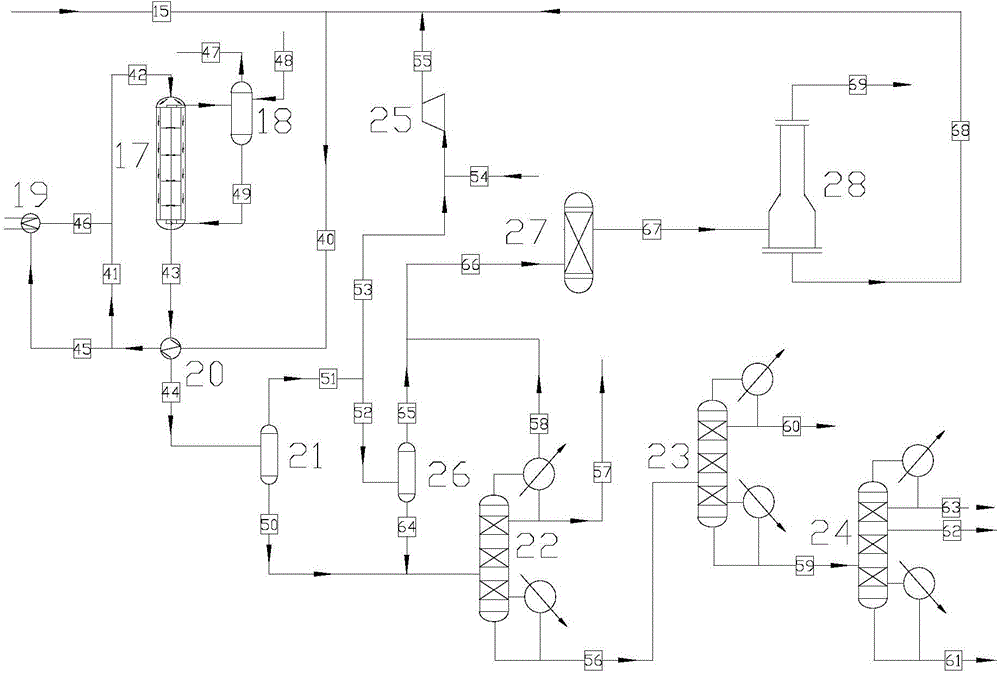

Activated carbon loaded compound metal catalyst, preparation method and application thereof.

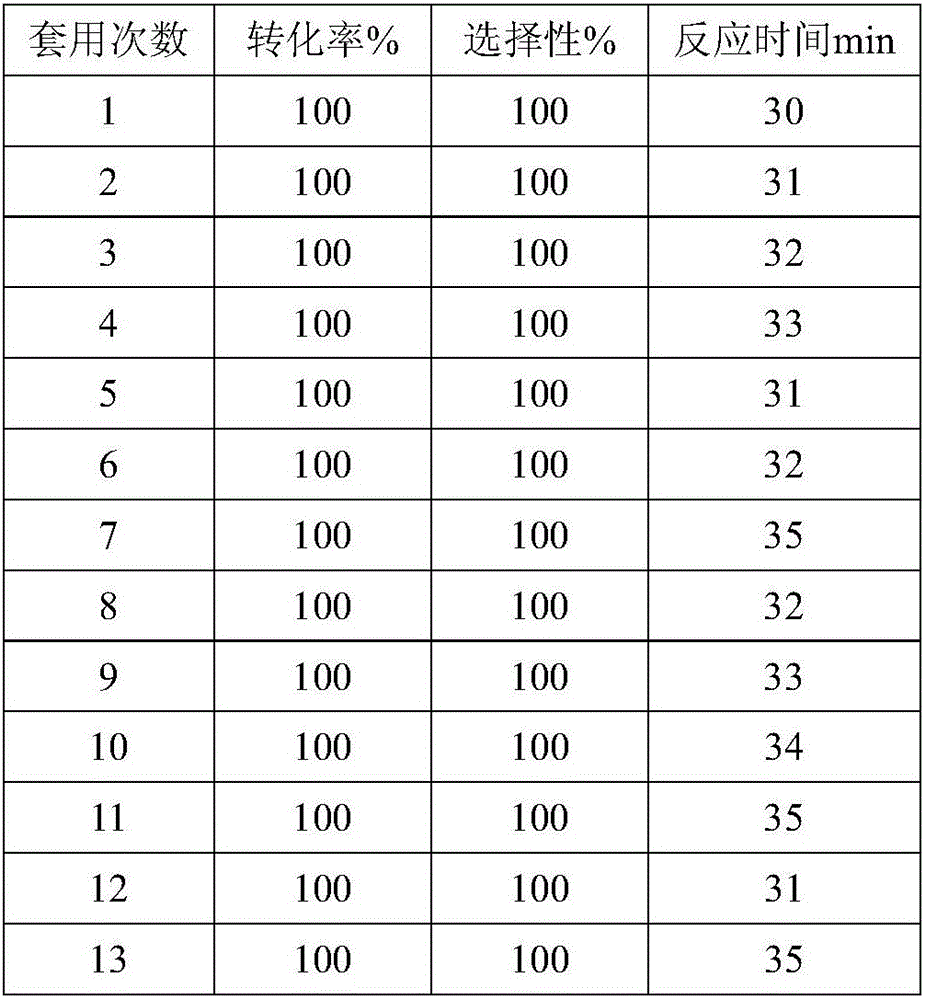

InactiveCN106179400AHigh catalytic activityFast hydrogenation reactionOrganic compound preparationChemical recyclingNitro compoundBULK ACTIVE INGREDIENT

The invention provides an activated carbon loaded compound metal catalyst, a preparation method and application thereof. The catalyst is prepared from a carrier, an active ingredient and an auxiliary, wherein the carrier is activated carbon, the active ingredient is at least one of platinum, palladium and rhodium, and the auxiliary is at least one of iron, zinc, cobalt and copper. The catalyst can be applied to a reaction for synthesizing a corresponding amine compound by catalytic hydrogenation, and has high catalytic activity and high hydrogenation speed, the reduction process is effectively promoted by the using method, and a nitro group influenced by power supply group can be quickly reduced into amino by 100 percent. The catalyst is mild in conditions, good in stability and more in using times in the circular using process.

Owner:ZHEJIANG UNIV OF TECH

Auto-oxidation production of hydrogen peroxide via hydrogenation in a microreactor

InactiveCN101296860AIncrease profitFacilitate depositionHydrogen peroxideChemical/physical/physico-chemical microreactorsMicroreactorHydrogen

Hydrogen peroxide is prepared by an auto-oxidation method via hydrogenation in a microreactor. A working solution containing a reactive carrier compound is hydrogenated with hydrogen in a microreactor and is subsequently auto-oxidized to produce hydrogen peroxide.

Owner:FMC CORP

Coal direct hydro-liquefaction method

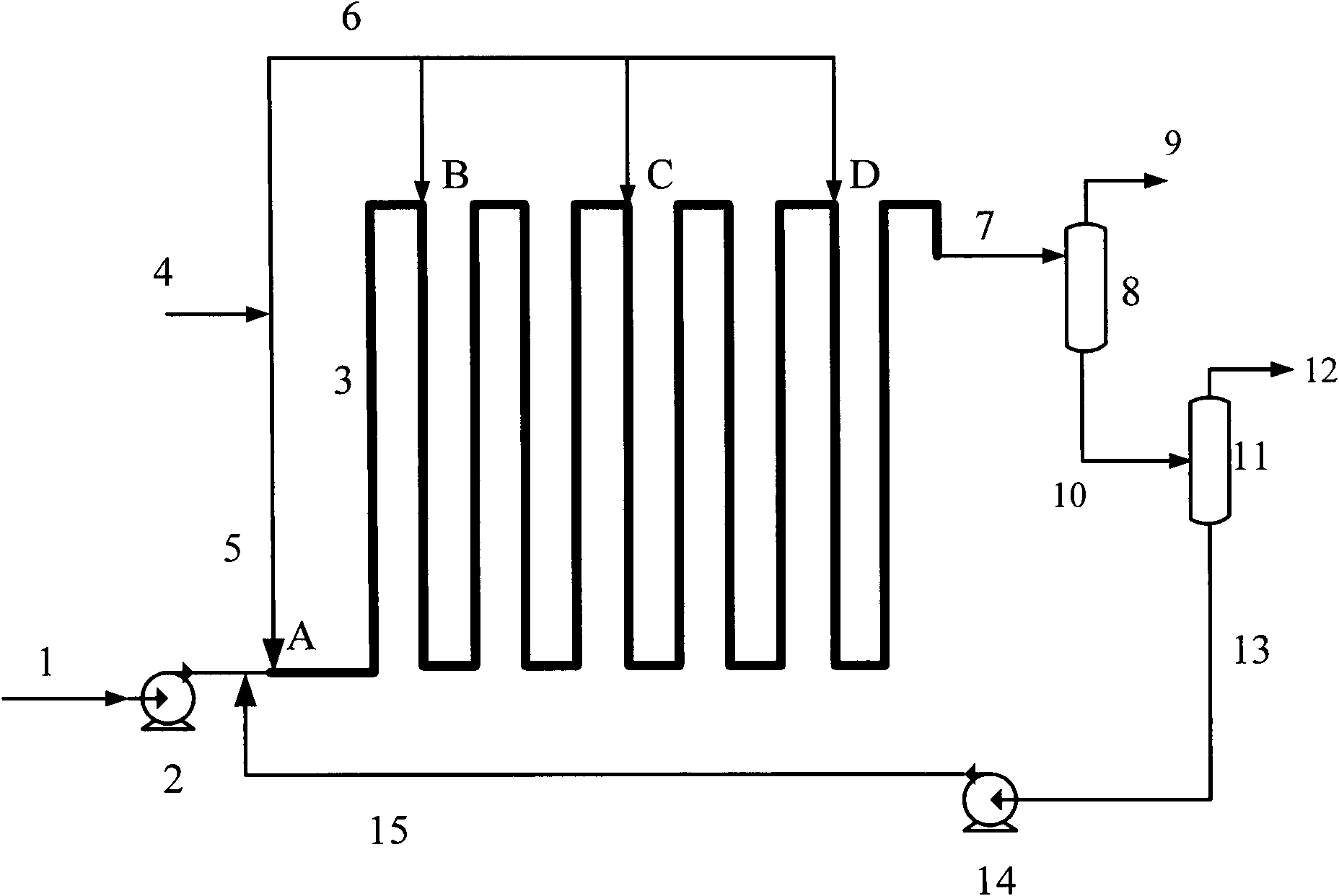

InactiveCN102234520AIncrease the rate of the hydrogenation reactionShort reaction timeLiquid hydrocarbon mixture productionSolventDecomposition

The invention provides a coal direct hydro-liquefaction method. According to the method, under a coal direct hydro-liquefaction reaction condition, a raw material mixture containing coal, a catalyst and a solvent contacts hydrogen in a tubular reactor, such that a liquefied product containing liquid hydrocarbon oil is obtained. According to the method, hydrogen is added into the tubular reactor from at least two positions of the tubular reactor. Compared with prior arts, the method employs a small-diameter tubular reactor which is easy to manufacture and to install. With the method provided by the invention, excess hydrogen amount during a reaction process is reduced, the utilance of hydrogen and the reactor is improved, the reaction time is reduced, secondary decomposition of the target product is reduced, and condensing and coking reactions of macro-molecule organic compounds are reduced.

Owner:杨元一 +2

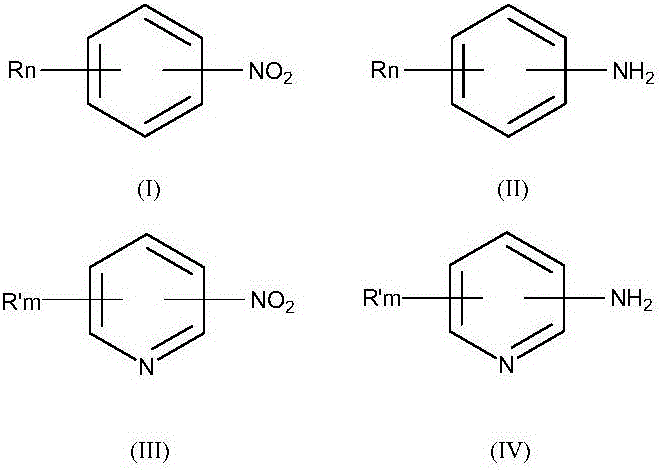

Iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as method

InactiveCN110639553ASimple compositionLow costOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDiaminodiphenyl etherPtru catalyst

The invention discloses an iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as a method. The catalyst takes carbon coated foam copper as a carrier and loads Fe, Co and noble metal; and the mass contents of the Fe, the Co and the noble metal in the catalyst are sequentially 0.1 to 1.0 percent, 0.1 to 0.8 percent and 0.1 to 0.9 percent. The4,4-diaminodiphenyl ether is continuously produced by adopting the iron cobalt composite carbon copper catalyst, by taking 4,4-dinitrodiphenyl ether as a raw material and by performing nitro hydrogenation reaction on a catalyst bed by a trickle bed, the catalytic reaction efficiency is high, the reaction heat is concentrated, the carbon coated foam copper carrier can disperse the active componentsof the catalyst well, also can rapidly remove reaction heat and guarantees that the reaction is conducted within the proper temperature range rapidly and stably, the raw material conversion rate is 100 percent, the selectivity of target products is more than 99.9 percent, the catalyst property is stable, the catalytic reaction is too simple the catalytic reaction heat is recoverable, the heat energy utilization efficiency is high, and environmental friendliness is realized.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

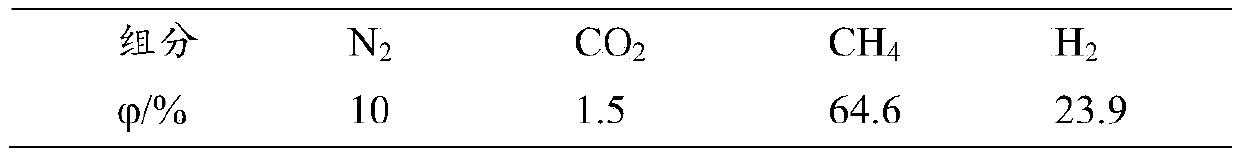

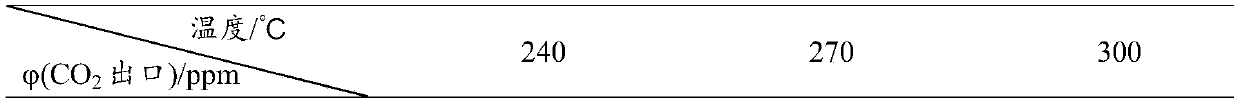

CO2 low-temperature methanation catalyst, preparation and application thereof

ActiveCN109529840AHigh strengthExcellent CO

<sub>2</sub>

low temperature methanation activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationActive component

The invention provides a CO2 low-temperature methanation catalyst, which belongs to the technical field of the methanation catalyst. The catalyst comprises a carrier, an active component and an auxiliary agent, the carrier comprises Al2O3 and carbon nanotubes, the active component is NiO, and the auxiliary agent is selected from one or two of La2O3 and CeO2; by taking total mass percentage of thecatalyst, the content of the Al2O3 is 55 to 85 wt%, the content of the CNTs is 1 to 20 wt%, the content of the active component NiO is 10 to 25 wt%, and the content of the auxiliary agent is 0 to 5 wt%. The invention also provides a preparation method and application of the catalyst. The catalyst of the invention uses Al2O3-CNTs as a composite carrier to load metal nickel, which can significantlyimprove the low temperature stability of the catalyst. The catalyst of the invention has high strength and excellent CO2 low-temperature methanation activity, and the catalyst of the invention after high temperature operation has high low-temperature activity and good catalyst stability. The catalyst preparation method is simple, and has industrial application prospect.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Production process of neopentyl glycol

InactiveCN107311840AHigh yieldIncrease the rate of the hydrogenation reactionOrganic compound preparationCarbonyl compound preparationDistillationNeopentyl glycol

The invention relates to a production process of neopentyl glycol. The production process comprises the following steps: (1) mixing formaldehyde, isobutyraldehyde and triethylamine and performing condensation reaction to obtain a hydroxypentaldehyde solution; (2) adding methanol and a catalyst into the hydroxypentaldehyde solution obtained in the step (1) and performing hydrogenation reaction to obtain a neopentyl glycol solution; (3) purifying the neopentyl glycol solution obtained in the step (2) to obtain a neopentyl glycol finished product, wherein the catalyst in the step (2) is a molybdenum and chromium-modified active copper catalyst. The purifying method in the step (3) comprises the following steps: extraction, reduced-pressure distillation twice, gasification and condensation-crystallization. The production process of the neopentyl glycol, provided by the invention, has the benefits that less wastewater is produced, the requirements for equipment are low, the production cost is low, the production process is short, and the product purity can reach 99.7 percent.

Owner:HENGYANG YISHUN CHEM CO LTD

Hydrogenation process for producing hydrogen peroxide by anthraquinone method

ActiveCN104555935APrevent deficienciesAvoid excessive hydrogenation reactionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGas phaseHydrogenation process

The invention discloses a hydrogenation process for producing a hydrogen peroxide by an anthraquinone method. The hydrogenation process comprises the following steps that: (1) two reactors are arranged in the hydrogenation process for producing the hydrogen peroxide by the anthraquinone method; a first current of fresh hydrogen and a working liquid serve as a feeding material I and perform hydrogenation in the first reactor; the reacted material is subjected to gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the first reactor; the rest of the liquid phase is reasonably optimized and modulated; the phenomenon that the reaction hydrogen is deficient or excessive is avoided; the hydrogenation completeness is realized; the liquid phase and the gas phase are mixed to serve as feeding material II and enter the second reactor; (2) a second current of fresh hydrogen and the feeding material II perform the hydrogenation in the second reactor; the reacted material is subjected to the gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the second reactor, and the rest of the liquid phase enters an oxidation process. According to the process disclosed by the invention, a hydrogenation process is optimized, and meanwhile, side effects are reduced, so that the hydrogenation is more uniform, and the service life of a catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

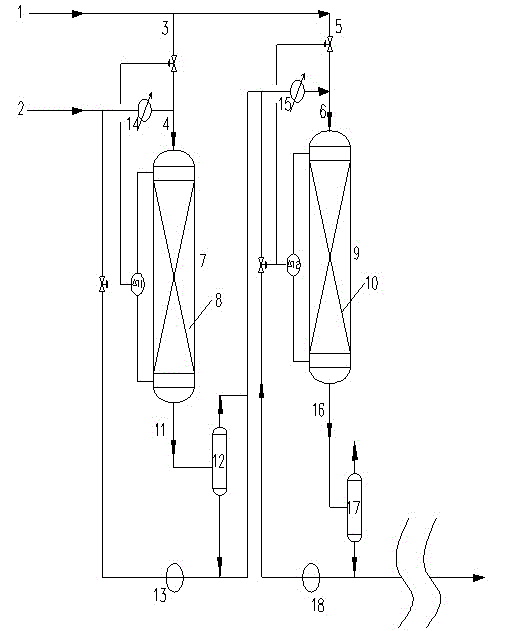

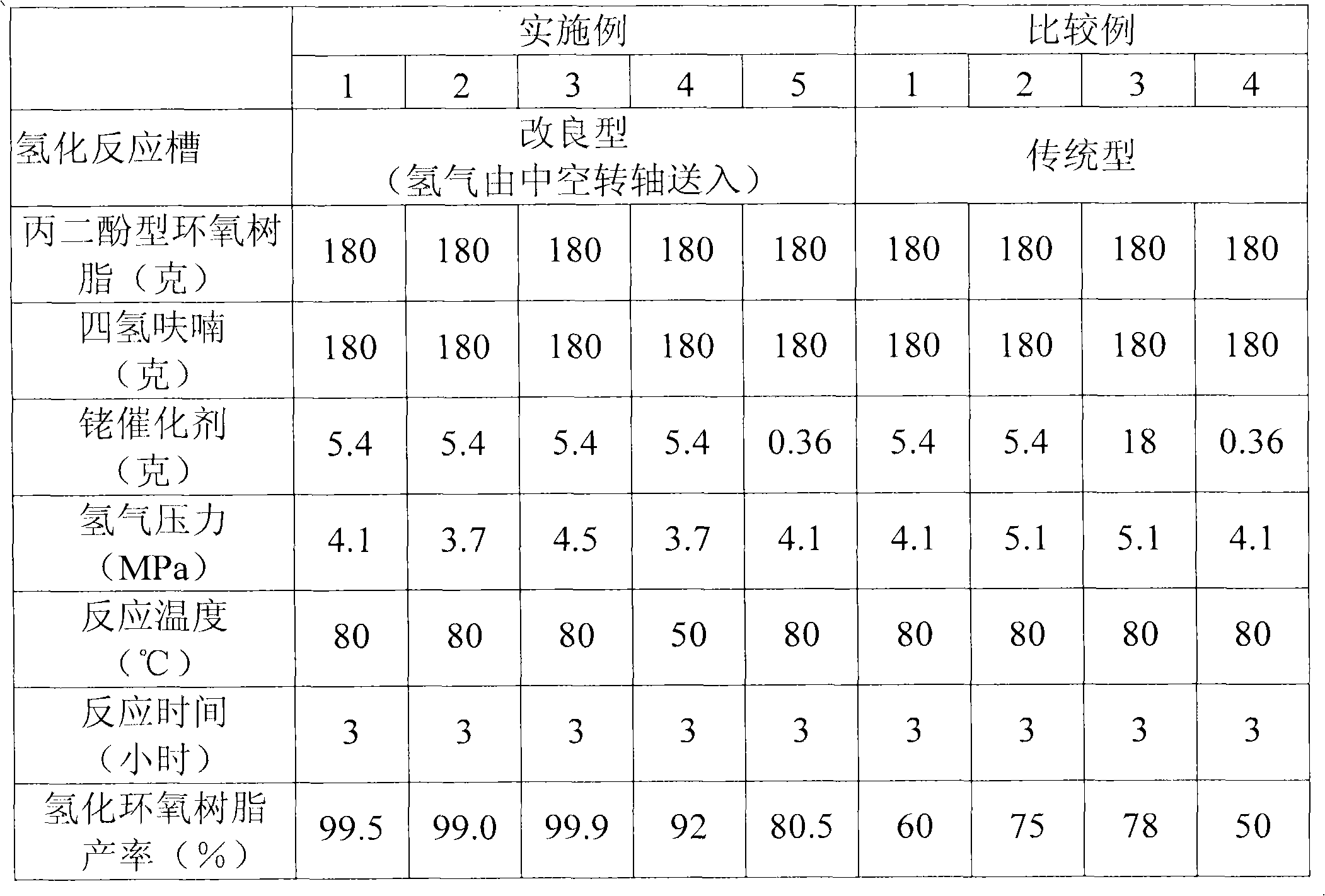

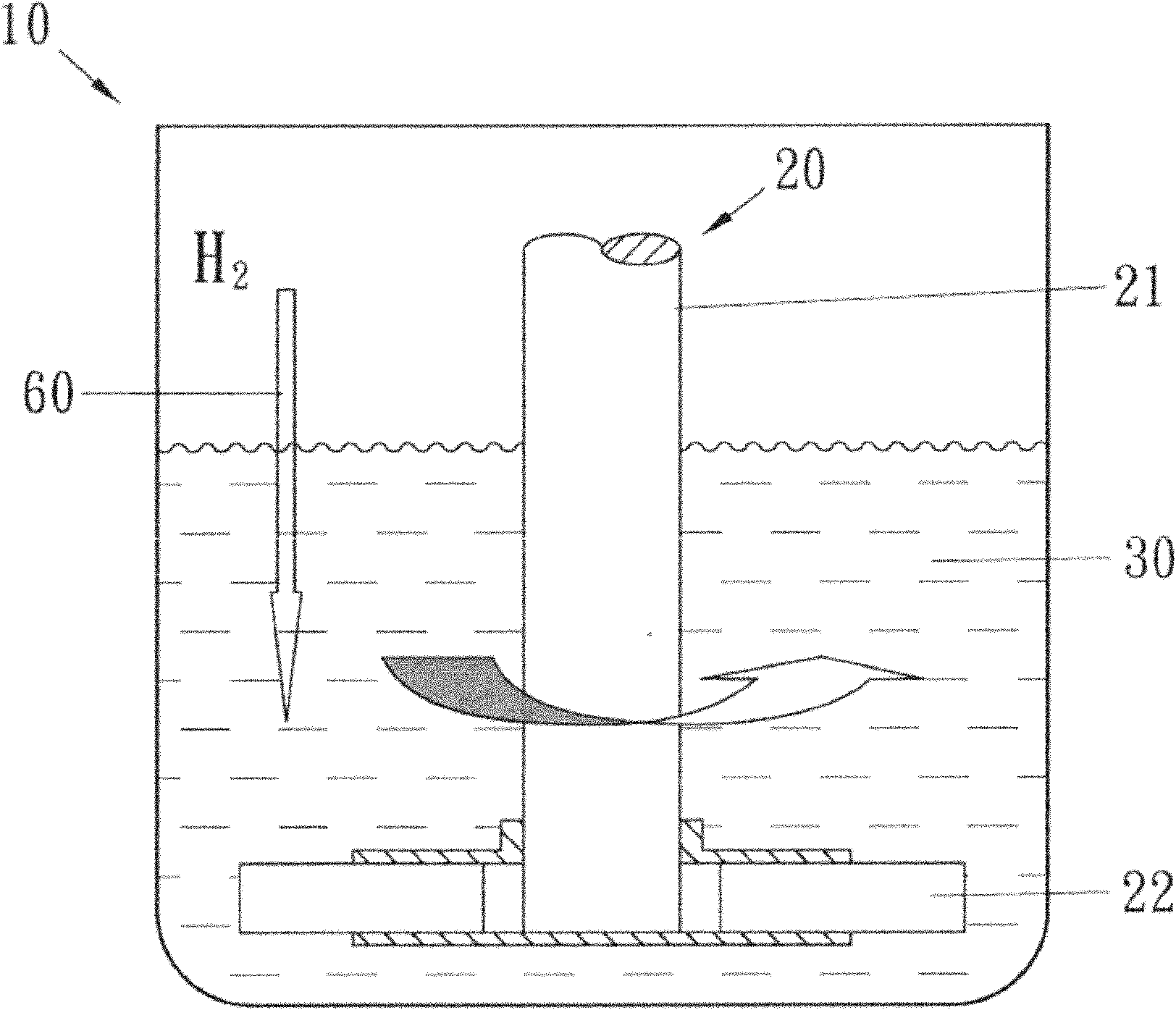

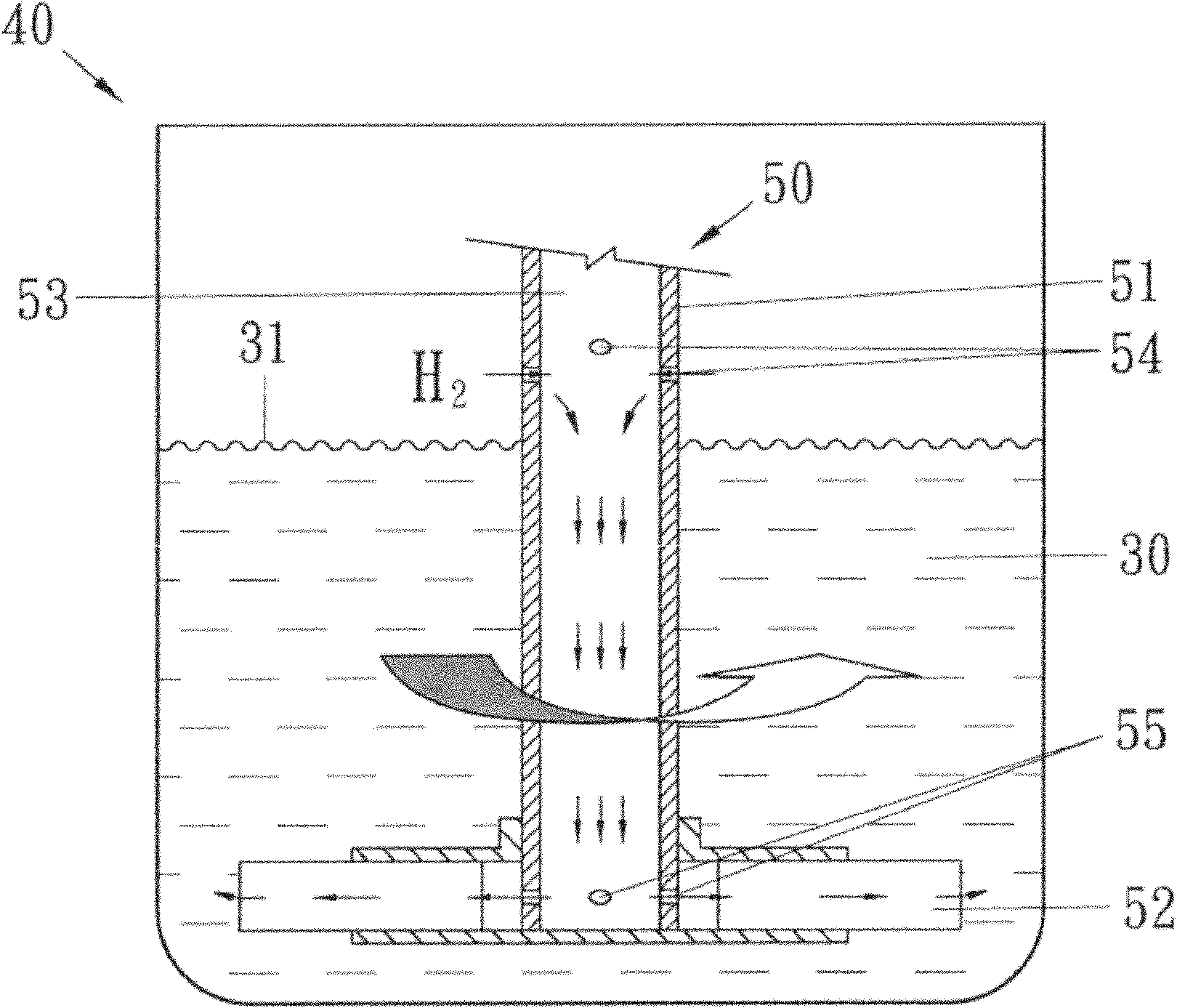

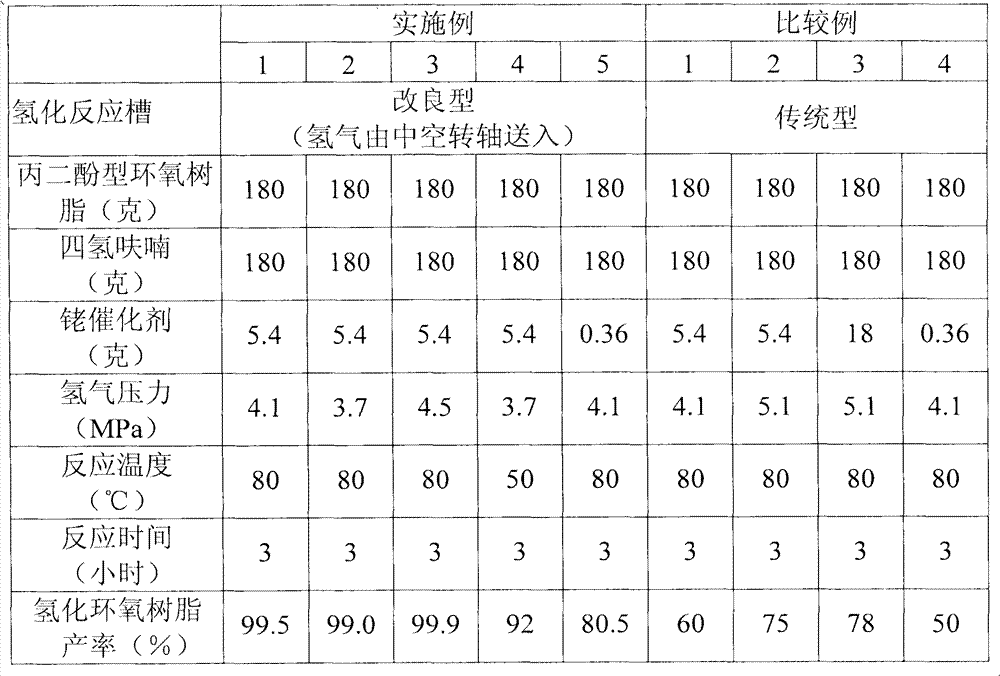

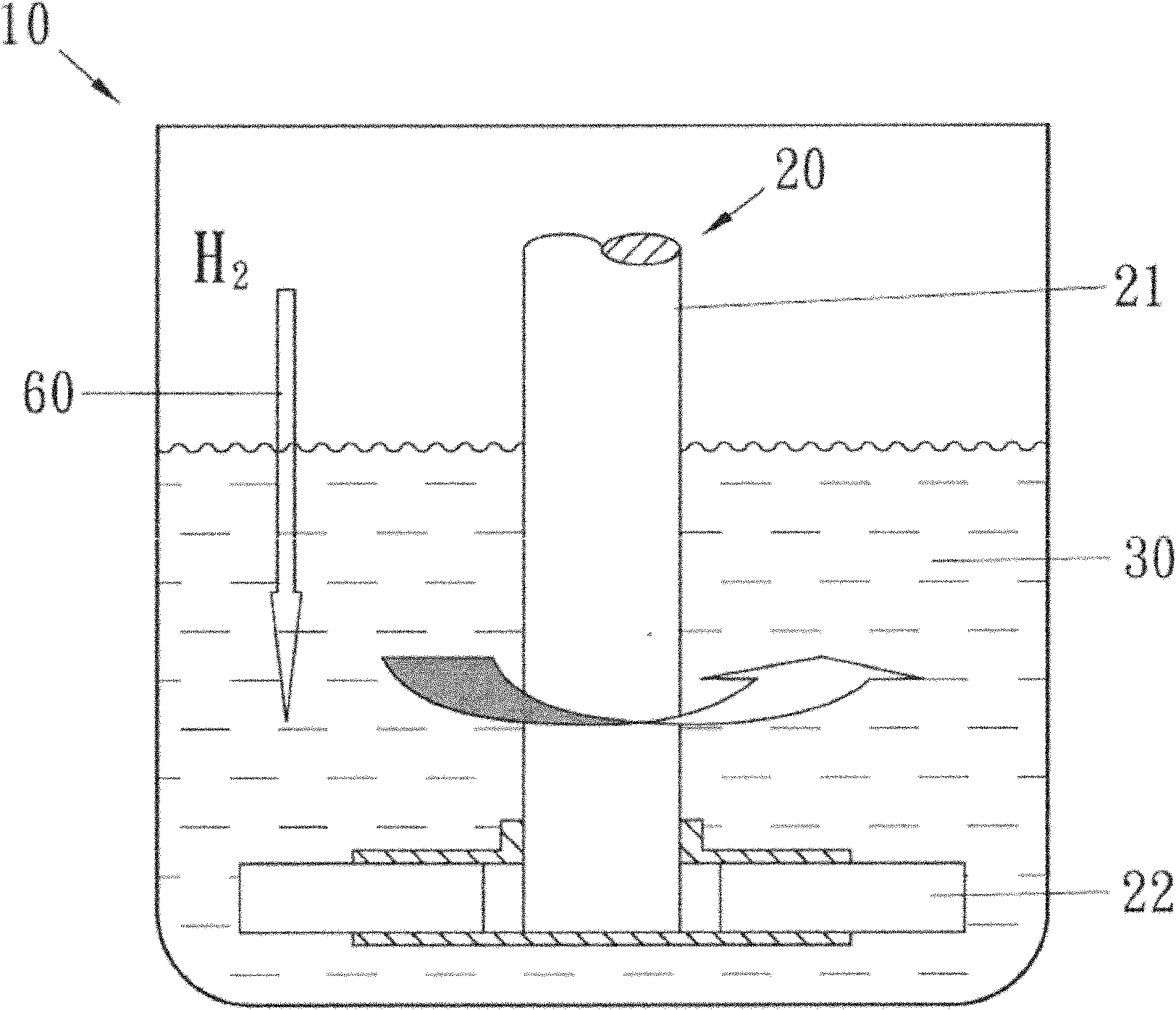

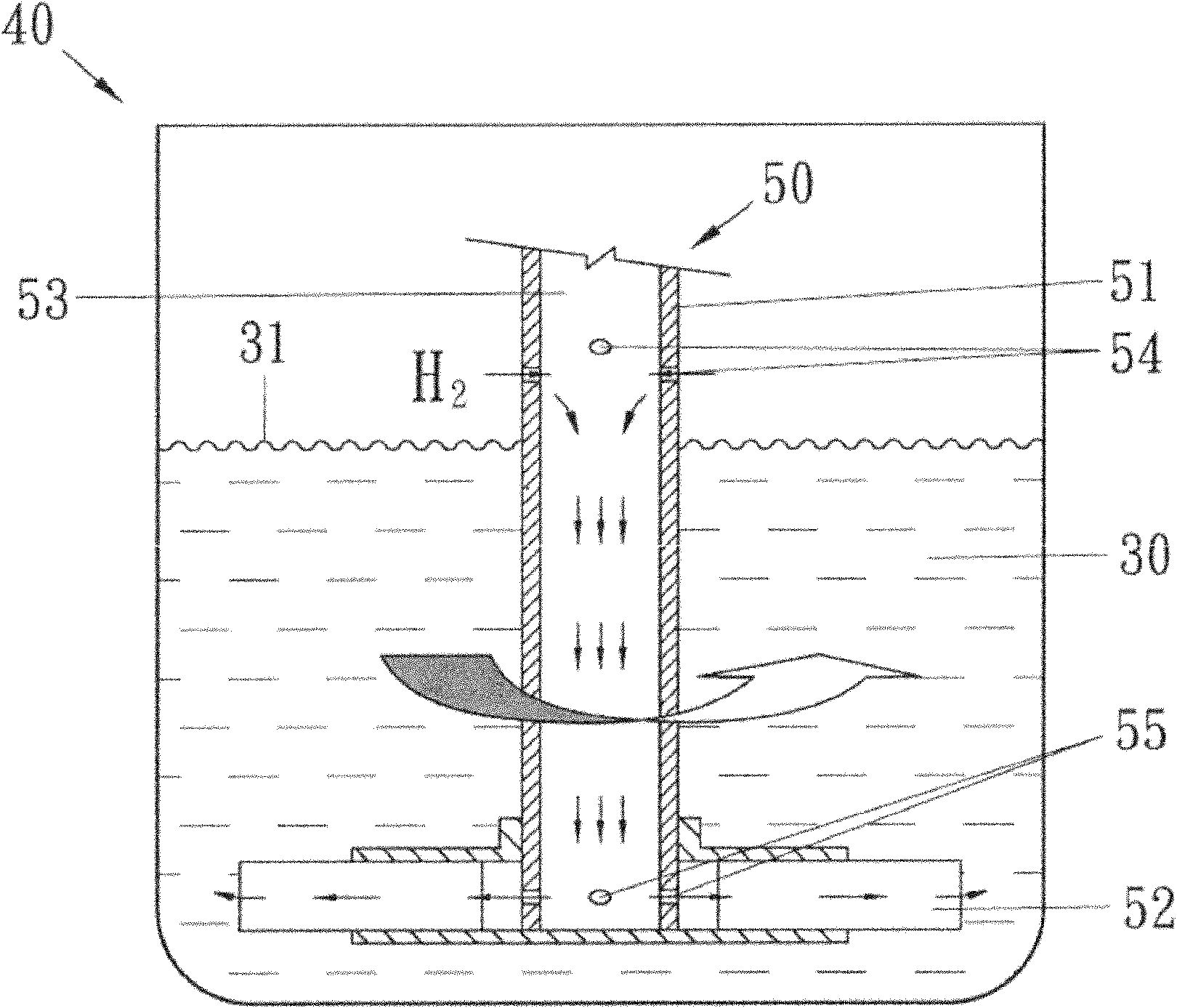

Hydrogenation method for improving yield of bisphenol-A type hydrogenated epoxy resin

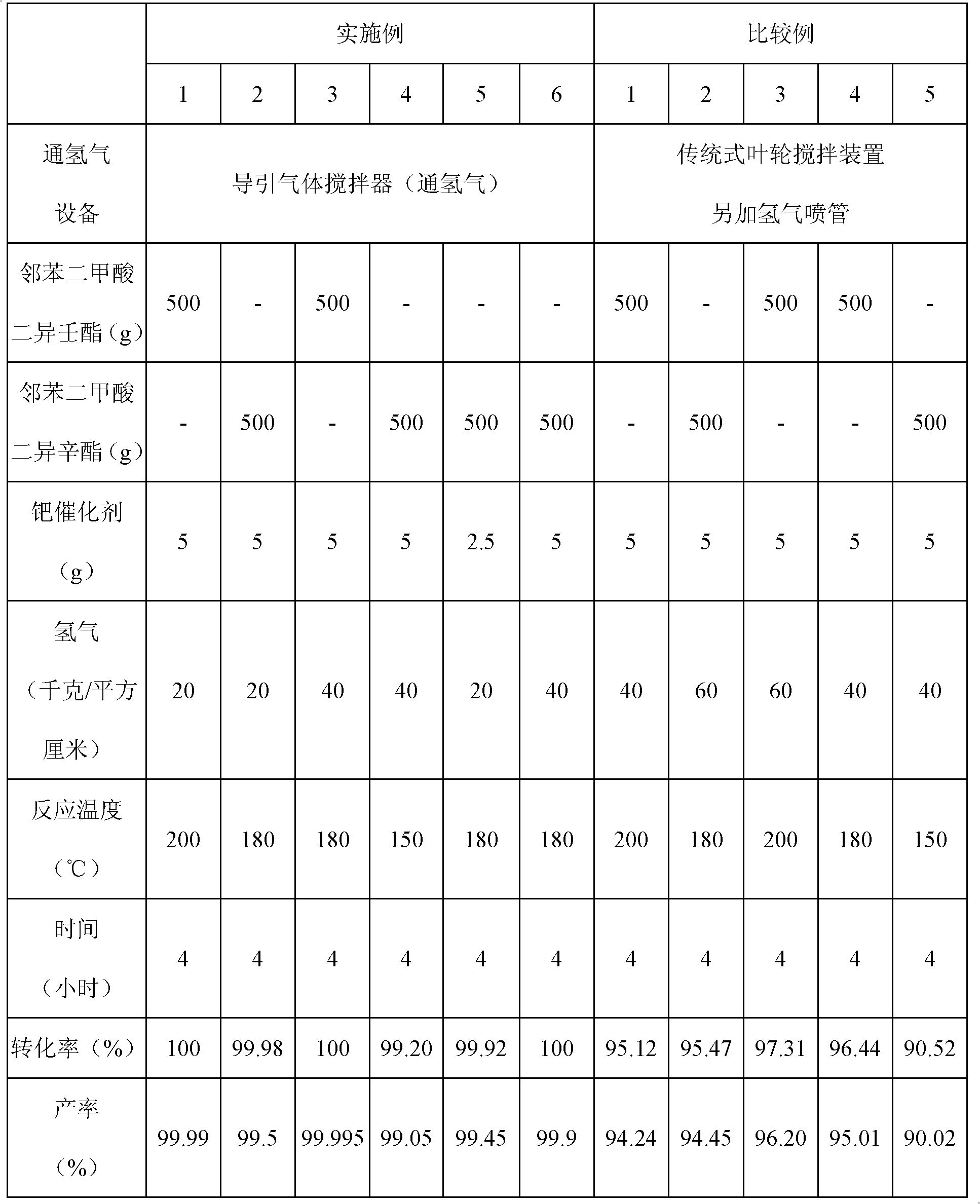

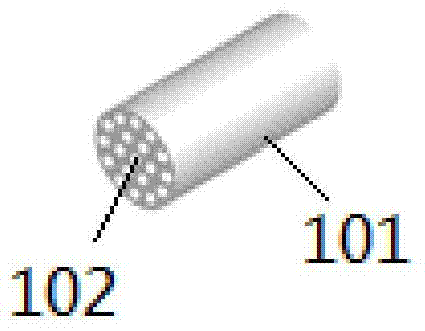

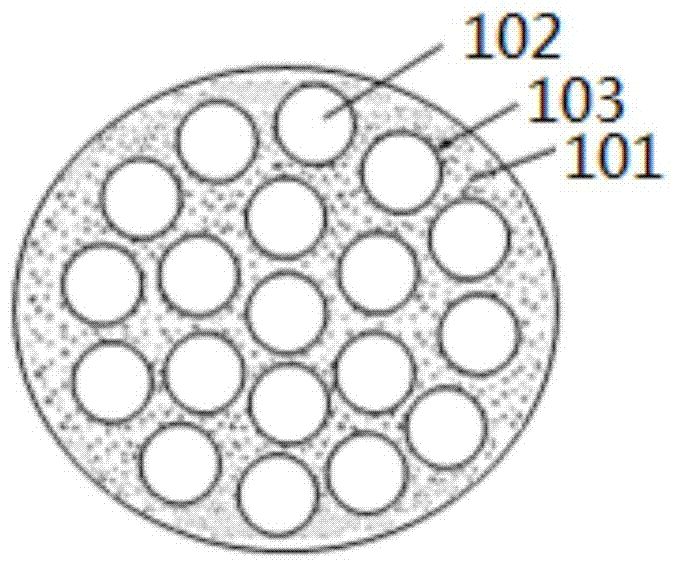

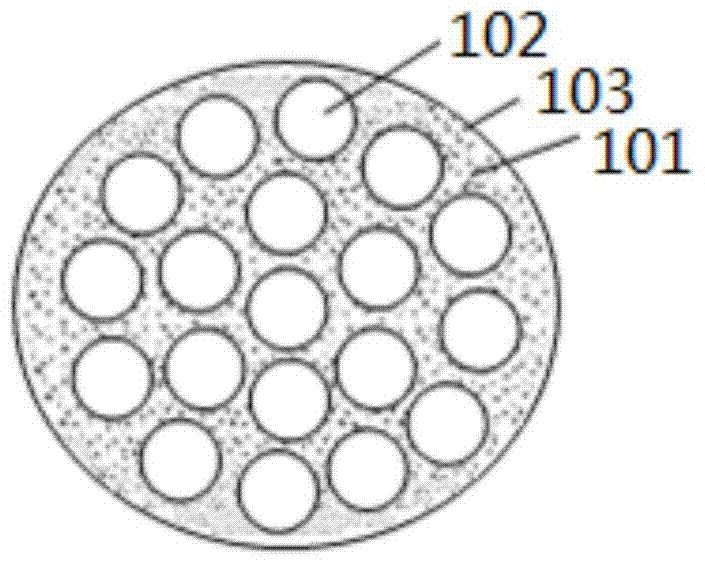

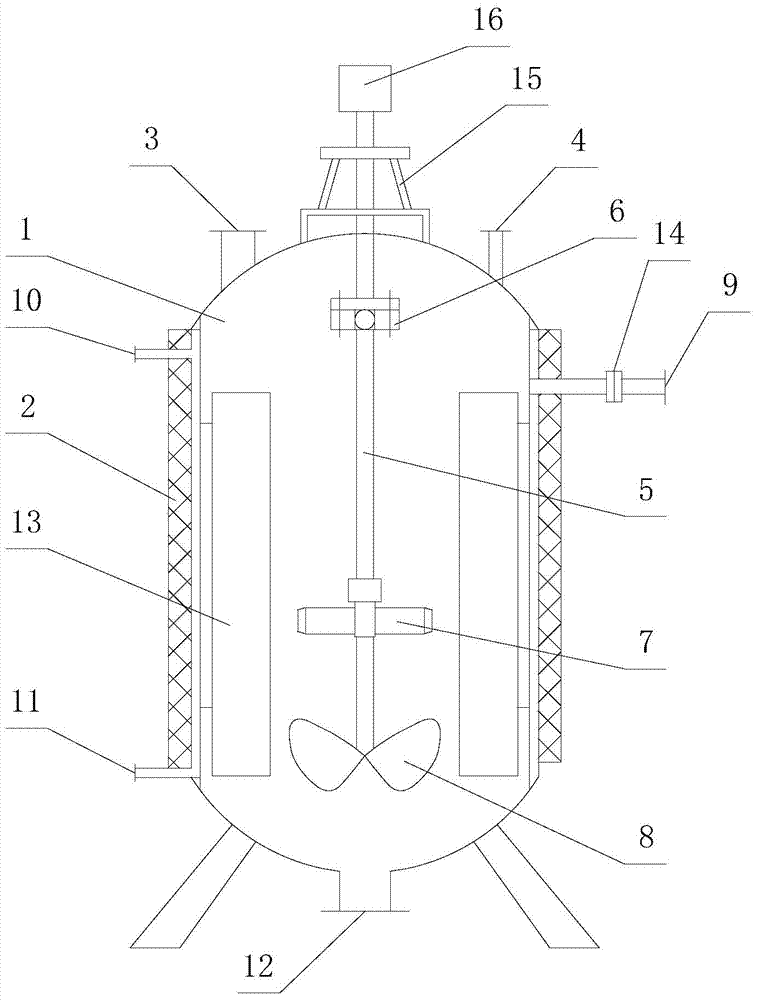

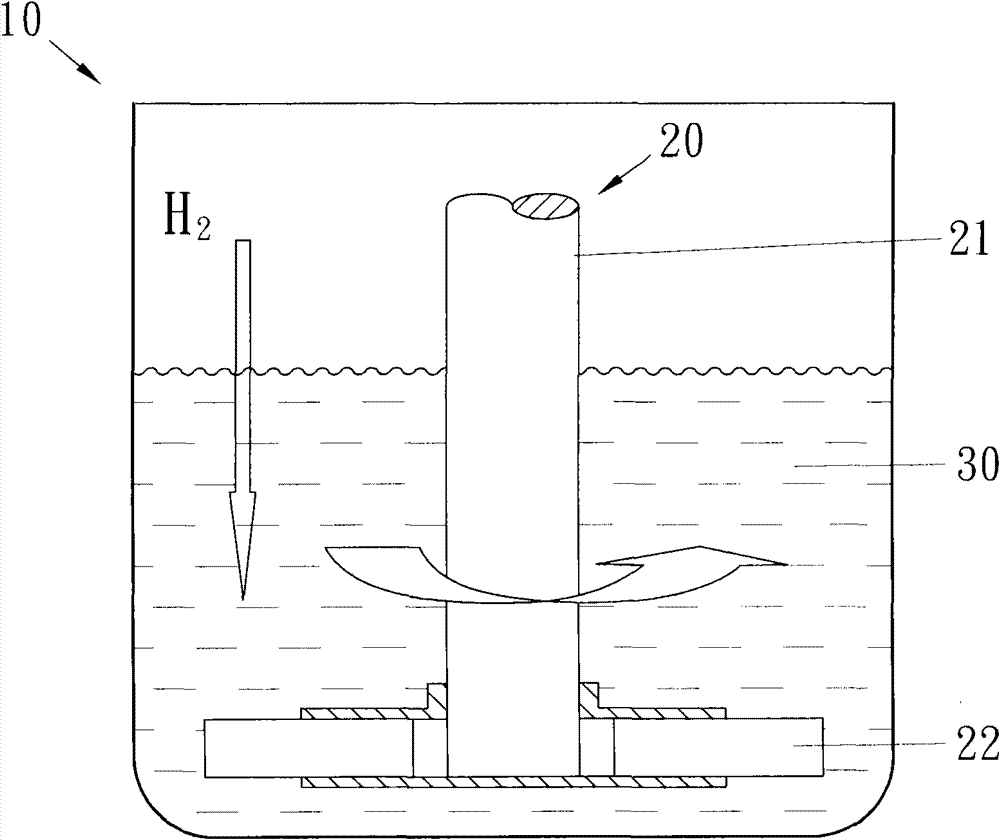

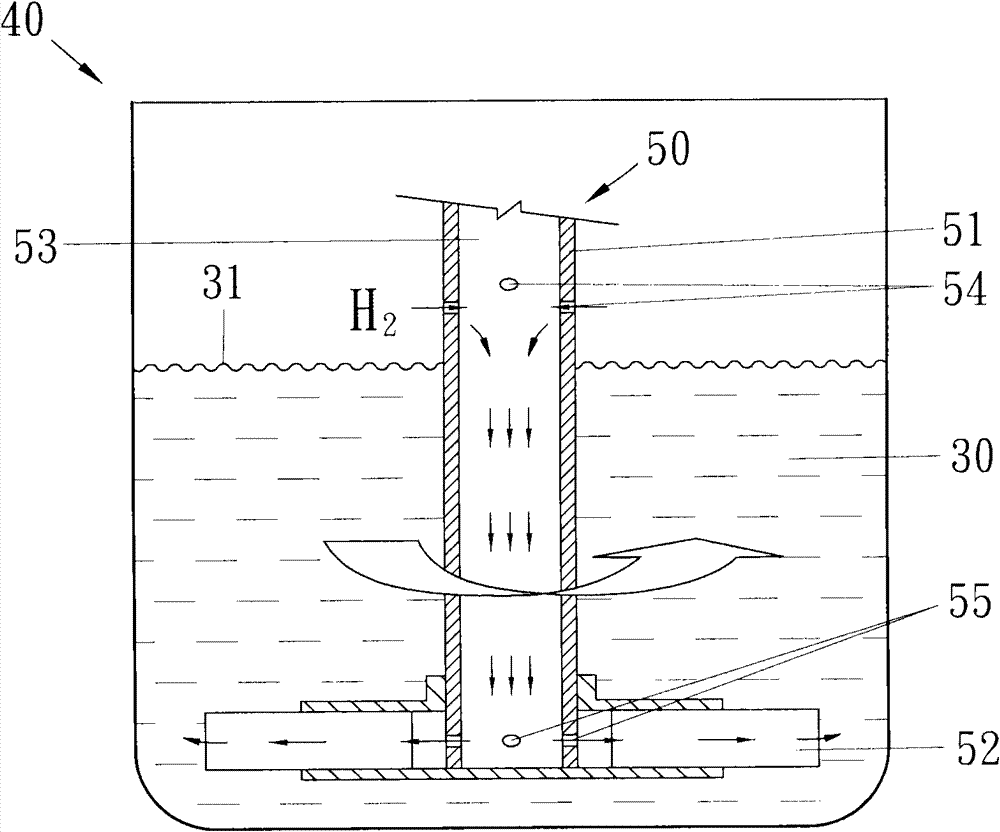

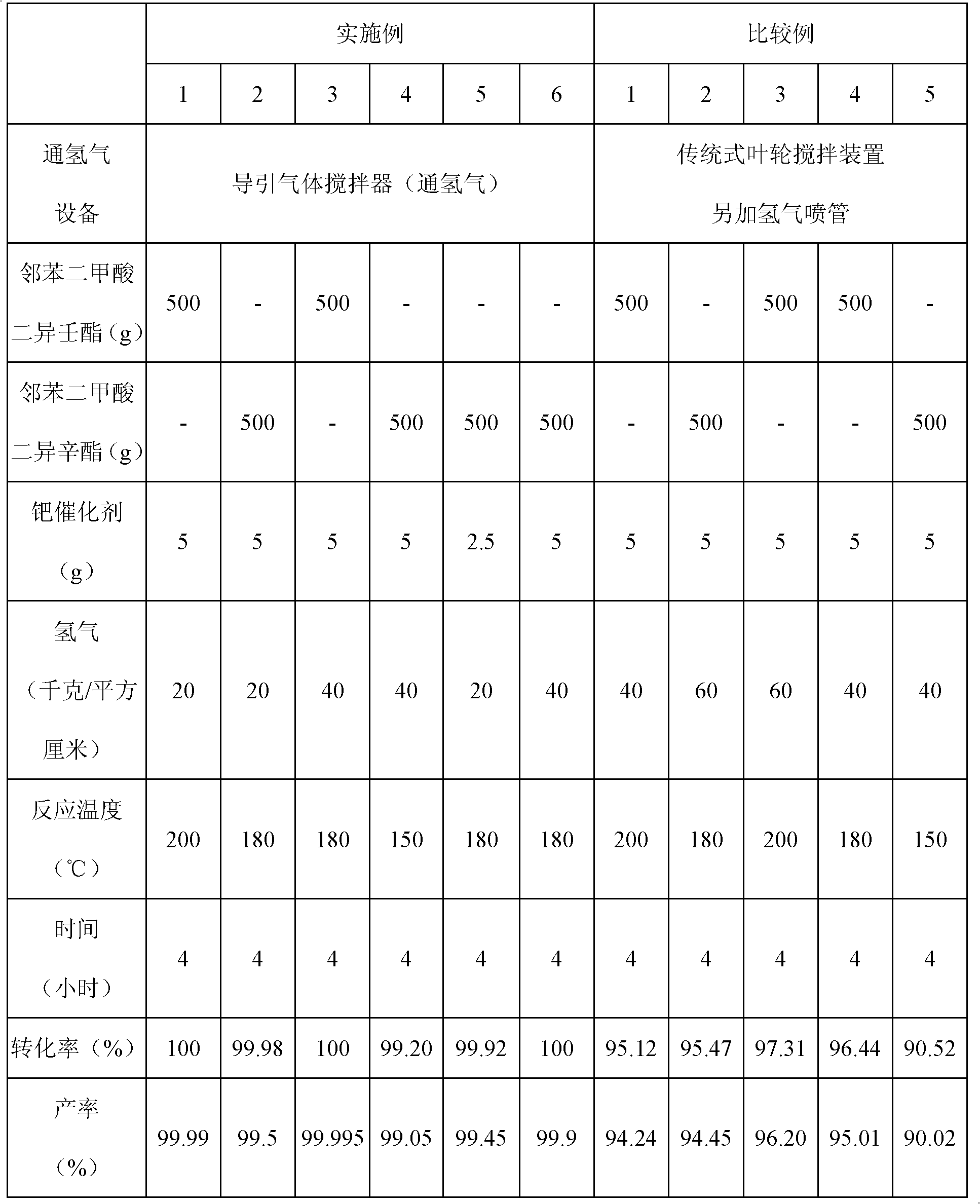

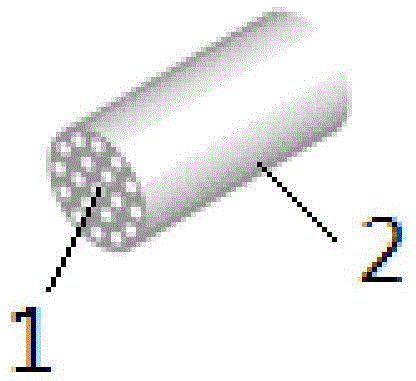

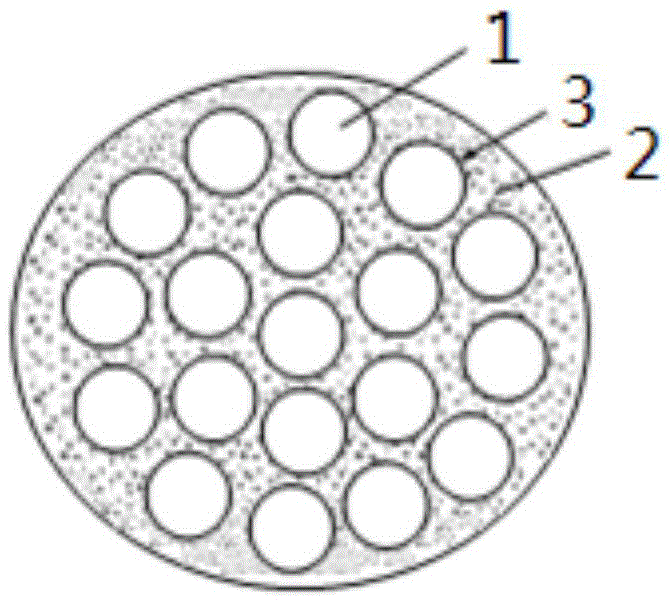

The invention discloses a hydrogenation method for improving the yield of a bisphenol-A type hydrogenated epoxy resin. The method comprises a step of uniformly dispersing hydrogen which is input into a hydrogenation reaction tank by using a guidance gas stirrer with aspiration, exhaust and stirring functions in the hydrogenation reaction tank through the aspiration, exhaust and stirring of the guidance gas stirrer. The method ensures that reaction fluid contains high-concentration dissolved hydrogen, so that a hydrogenation catalyst has extremely high activity and the rate of a hydrogenation reaction is accelerated; and the method can ensure that the hydrogenation reaction is performed at low temperature and under low pressure, even increase the yield of the bisphenol-A type hydrogenated epoxy resin to be between 99.0 and 99.9 percent, greatly reduce the construction and maintenance cost of the hydrogenation reaction tank, and improve economic benefit.

Owner:NANYA PLASTICS CORP

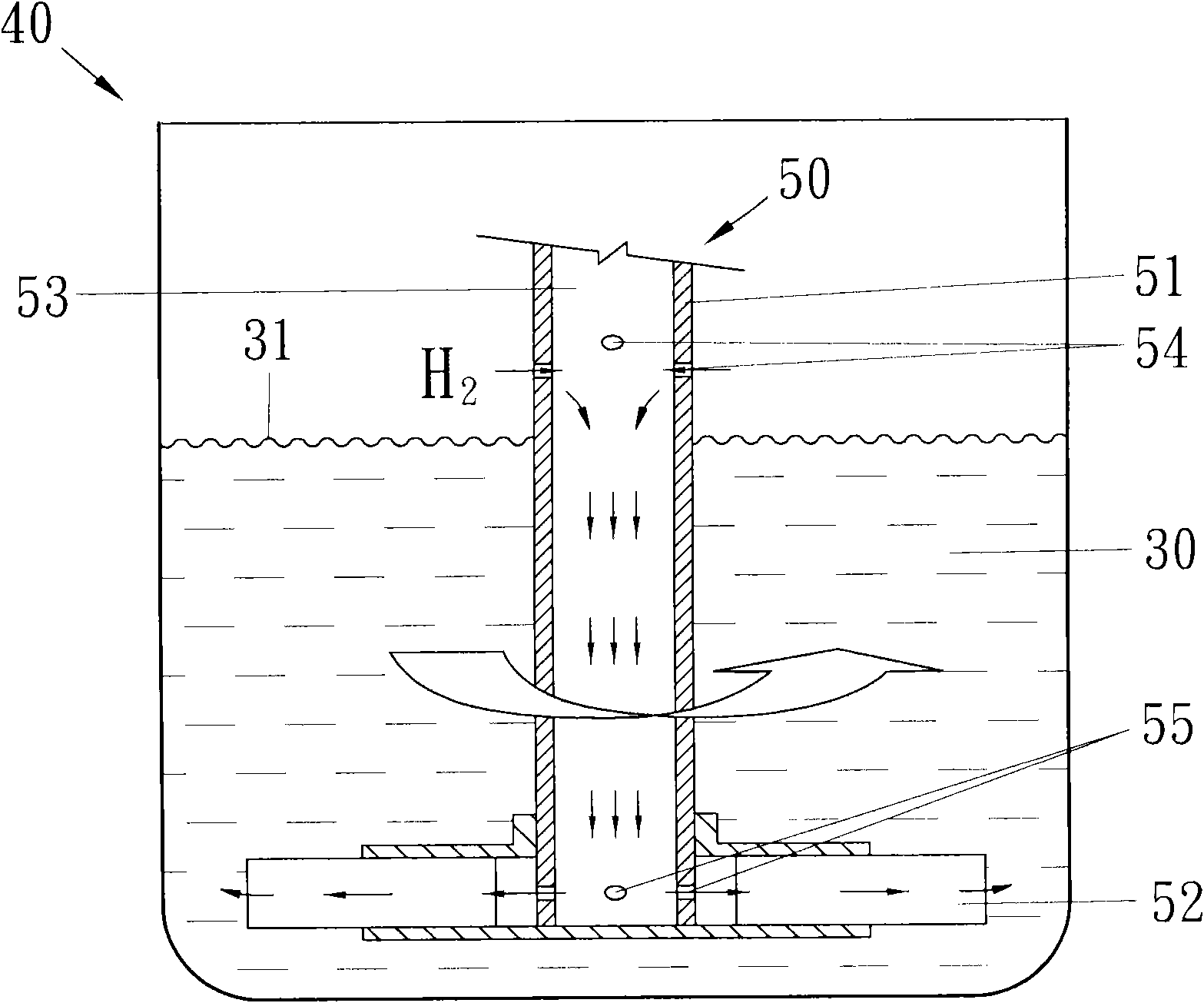

Method for preparing cyclohexane carboxylic ester from benzene polycarboxylic ester

ActiveCN102153469AImprove contact efficiencyLow operating pressureOrganic compound preparationCarboxylic acid esters preparationBenzeneHydrogenation reaction

The invention relates to a method for preparing cyclohexane carboxylic ester from benzene polycarboxylic ester, aiming at improving a hydrogenation method of the benzene polycarboxylic ester. In the method, the benzene polycarboxylic ester is hydrogenated to form cyclohexane polycarboxylic ester by utilizing a reaction groove provided with a guidance air stirrer having an air extracting and discharging capability in the presence of a hydrogenation catalyst. The preparation method has the advantages that the operation pressure for hydrogenating the benzene polycarboxylic ester is reduced to the minimum, the hydrogenation reaction temperature is greatly reduced, and the yield obtained by hydrogenating the benzene polycarboxylic ester into the cyclohexane polycarboxylic ester is effectively improved.

Owner:NANYA PLASTICS CORP

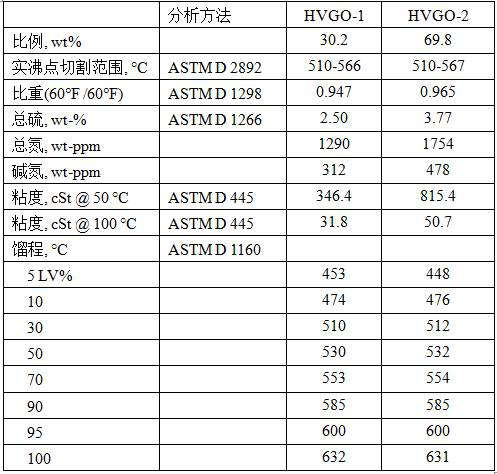

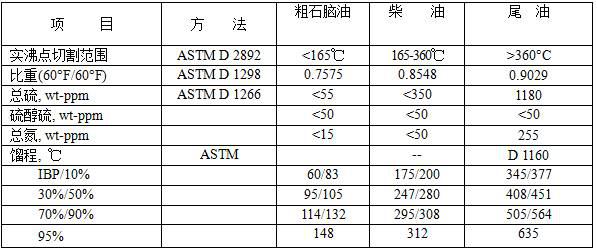

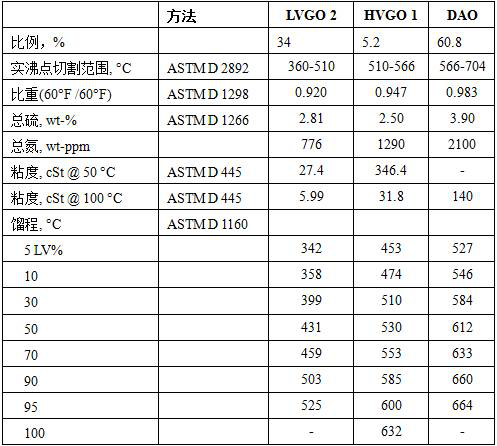

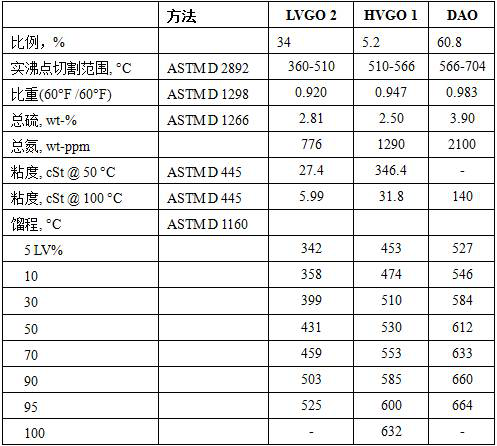

A kind of wax oil hydrogenation treatment method

ActiveCN104927902BIncrease the atomic ratio of hydrogen to carbonEfficient removalHydrocarbon oils treatmentWaxHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +2

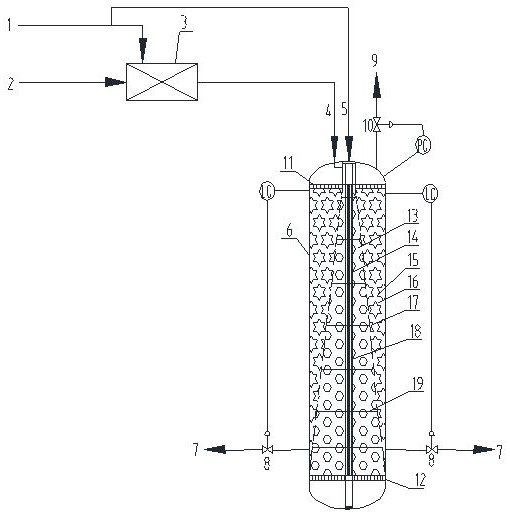

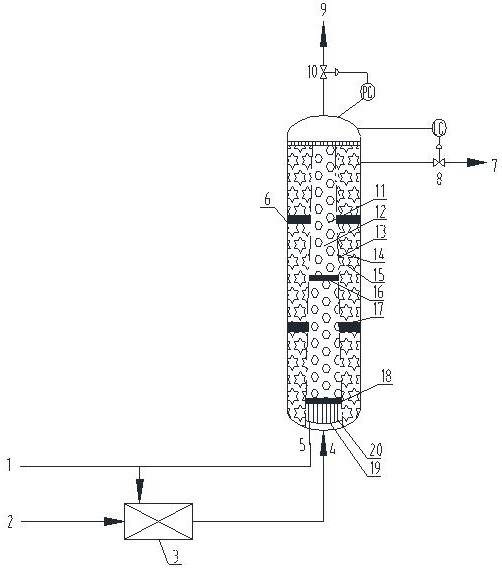

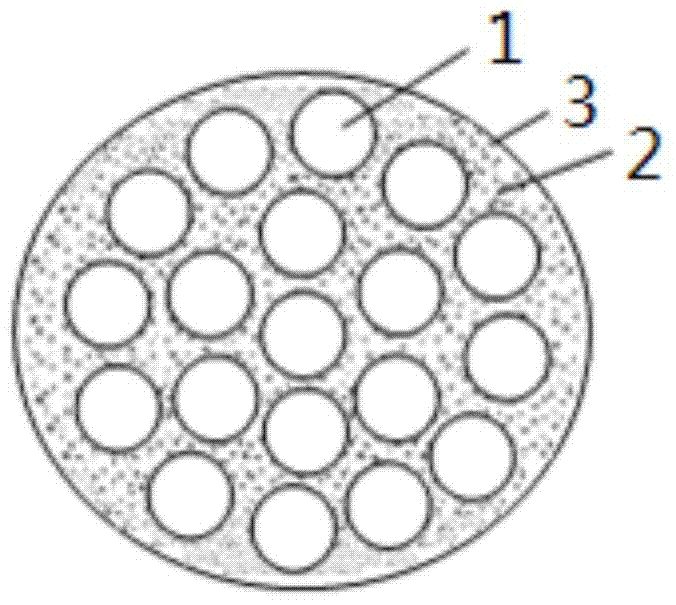

Liquid-phase hydrogenation reactor and hydrogenation process

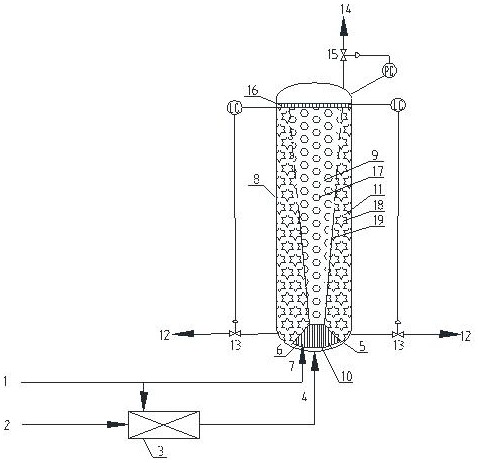

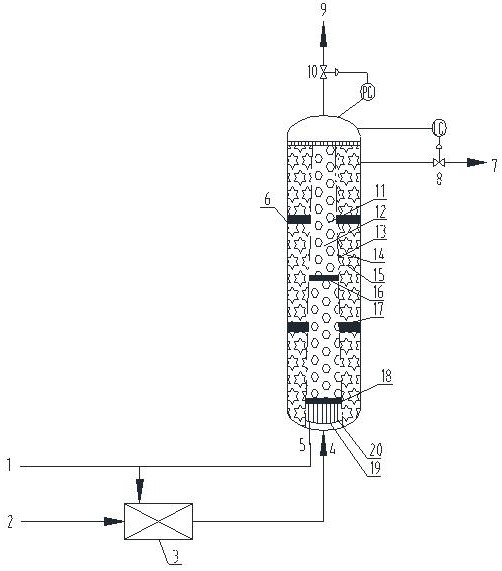

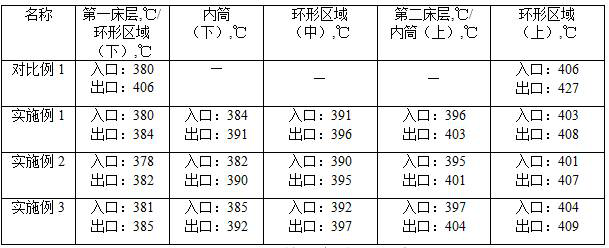

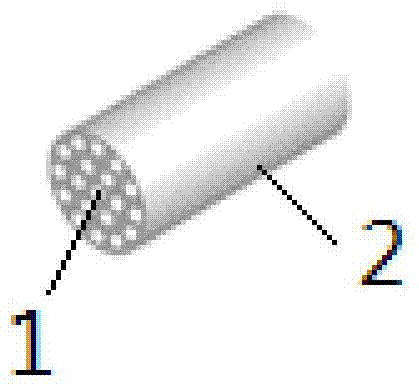

ActiveCN112705117AControl contact timeControl temperature riseTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention relates to a liquid-phase hydrogenation reactor and a hydrogenation process, the liquid-phase hydrogenation reactor comprises an inner cylinder and a reactor shell, the inner cylinder is conical, the top and the bottom of the inner cylinder are open, the edge of the bottom of the inner cylinder is hermetically connected with the inner wall of the reactor, and a plurality of small holes are formed in the wall of the inner cylinder; a ceramic membrane tube bundle is vertically arranged in the axial direction of the reactor and is communicated with external hydrogen; the inner cylinder is filled with a hydrogenation catalyst I, the annular cavity is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than that of the hydrogenation catalyst II; the reactor raw material inlet communicates with the top of the inner cylinder; the materials flow in the inner cylinder from top to bottom; the materials flow in the annular cavity from top to bottom. According to the method, the contact time of the material and the catalyst in the whole hydrogenation reaction process can be effectively controlled, so that the temperature rise of a catalyst bed layer is more uniform, the problems of severe heat release and reaction conversion rate inhibition in the reaction process are solved, and higher hydrogenation reaction rate and conversion rate in the whole liquid-phase hydrogenation reaction process are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heat-preservation type hydrogenation reactor

InactiveCN104258791AReasonable designImprove gas-liquid mixing effectLiquid-gas reaction as foam/aerosol/bubblesProduct gasSide reaction

The invention relates to the technical field of reactor equipment, and particularly relates to a heat-preservation type hydrogenation reactor. The heat-preservation type hydrogenation reactor comprises a tank body with a hollow interlayer structure, wherein a steam inlet and a steam outlet which are used for conveying steam to a hollow interlayer are formed in the tank body, a hollow mixing shaft connected with a mixing motor is suspended at the center of the tank body, a gas sucking hole, a gas self-suction paddle and a propelling mixing blade are sequentially and fixedly arranged on the mixing shaft from top to bottom; a feeding hole and a hydrogenation hole are formed in an end cover of the tank body, a discharging hole is formed in the upper-half part of the side wall of the tank body, and a heat-transferring plate is fixedly arranged on the inner wall of the tank body. The heat-preservation type hydrogenation reactor is reasonable in design and relatively small in probability of side reaction; the gas-liquid mixing effect is improved, and the hydrogenation reaction rate is increased.

Owner:诸文伟

Heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116AReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesMaterials scienceCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

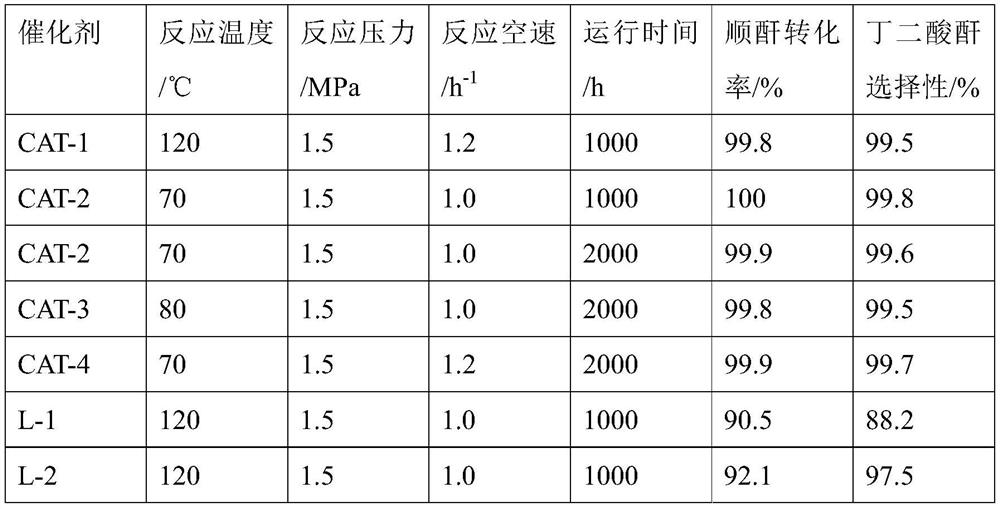

Non-noble metal catalyst for preparing succinic anhydride by liquid-phase continuous hydrogenation of maleic anhydride and preparation method of non-noble metal catalyst

PendingCN114289028AIncrease component contentImprove water absorptionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystReaction temperature

The invention provides a non-noble metal catalyst for preparing butanedioic anhydride through maleic anhydride liquid-phase continuous hydrogenation. A catalyst carrier is prepared by mixing, kneading and forming a copper precursor, a part of a nickel precursor, a colloidal solution of a first auxiliary agent and pseudo-boehmite powder, and then drying and roasting to prepare a carrier containing active metal. And then loading the residual active metal nickel and a second auxiliary agent by adopting an equivalent-volume impregnation method to prepare the catalyst. The catalyst comprises the following components in percentage by weight (in terms of oxide): 20%-30% of nickel oxide, 2%-5% of copper oxide, 0.1%-5.0% of a first aid, 0.1%-2.0% of a second aid and the balance of aluminum oxide. The catalyst has the advantages of simple preparation process, easiness in industrial production, wide reaction temperature range, high activity, high selectivity and high stability, and can be used for treating high-concentration and high-airspeed materials.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A liquid phase hydrogenation reactor and hydrogenation process

ActiveCN112705117BControl contact timeControl temperature riseTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention discloses a liquid-phase hydrogenation reactor and a hydrogenation process, comprising an inner cylinder and a reactor shell, the inner cylinder is conical, the top and bottom of the inner cylinder are open, the bottom edge is tightly connected with the inner wall of the reactor, and the inner cylinder is open. A number of small holes are opened on the cylinder wall; a ceramic membrane tube bundle is vertically arranged on the axial direction of the reactor, and the ceramic membrane tube bundle communicates with external hydrogen; the inner cylinder is filled with hydrogenation catalyst I, the annular cavity is filled with hydrogenation catalyst II, and hydrogenation catalyst I The activity of the catalyst is higher than that of the hydrogenation catalyst II; the inlet of the raw material of the reactor is connected to the top of the inner cylinder; the flow mode of the material in the inner cylinder is from top to bottom; the flow mode of the material in the annular cavity is from top to bottom. The invention can effectively control the contact time between the material and the catalyst in the whole process of the hydrogenation reaction, make the temperature rise of the catalyst bed more uniform, solve the problems of severe exotherm and inhibit the reaction conversion rate in the reaction process, and realize the whole liquid phase hydrogenation reaction process Both achieve higher hydrogenation reaction rate and conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

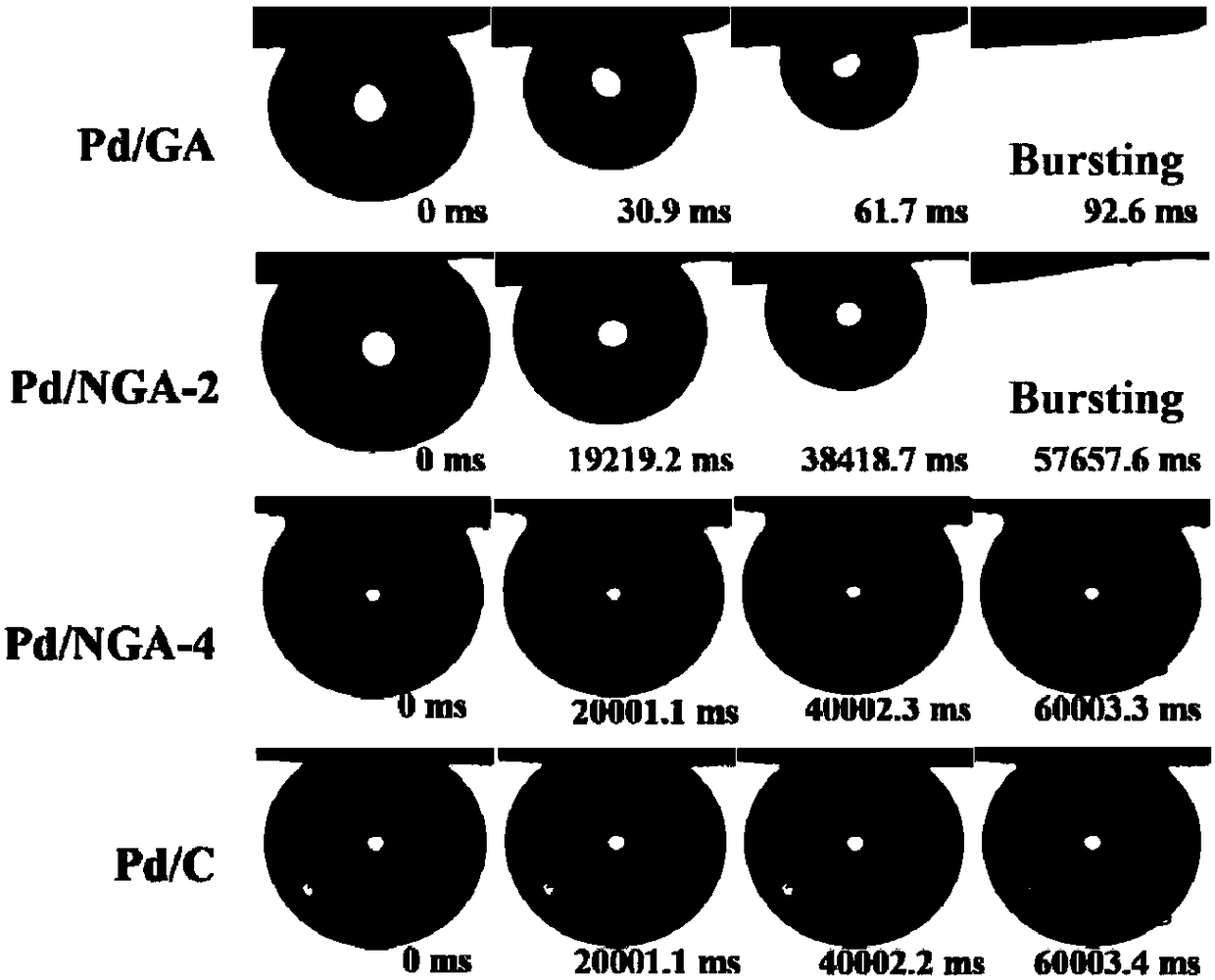

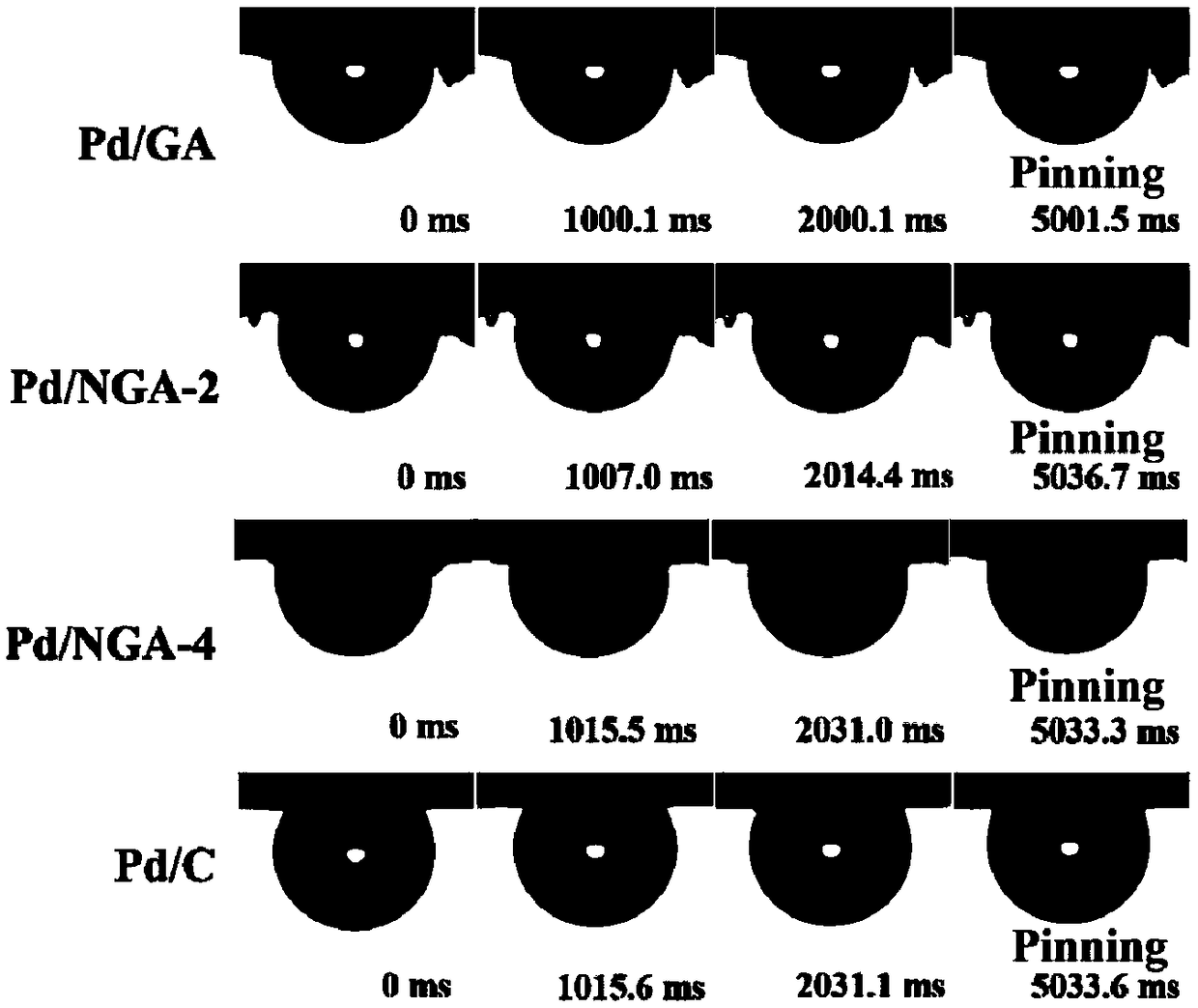

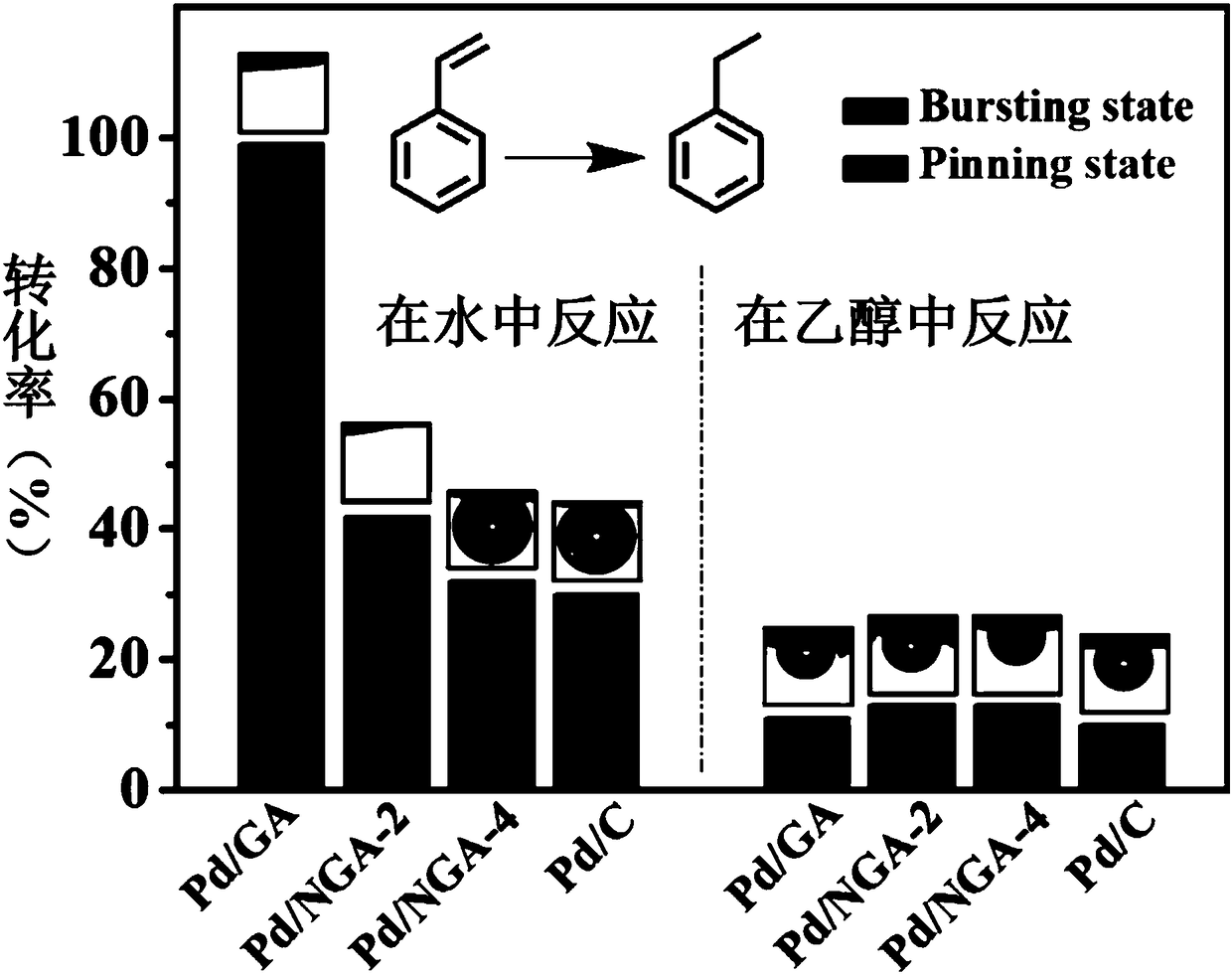

Multi-phase catalytic hydrogenation reduction method of unsaturated compound

ActiveCN108299207AFast adsorption spreadingIncrease the concentration of hydrogenOrganic compound preparationHydrocarbon by hydrogenationHydrogenation reactionDouble bond

The invention discloses a multi-phase catalytic hydrogenation reduction method of an unsaturated compound. The method comprises a step of carrying out multi-phase catalytic hydrogenation reaction to reduce the unsaturated compound; the multi-phase catalytic hydrogenation reaction takes water as a solvent and a hydrophobic and atmophile material as a catalyst. According to the multi-phase catalytichydrogenation reduction method, hydrophobic and atmophile properties of the catalyst are utilized, so that hydrogen gas can be rapidly adsorbed and spread on the surface of the catalyst, the surfacehydrogen concentration of the catalyst is improved, and the hydrogenation reaction speed is improved; a conventional pressurizing method is changed, so that requirements on equipment and dangerousnessare reduced. The atmophile catalyst Pd / GA can be used for hydrogenation of double bonds, nitryl and an aldehyde group under normal pressure, and is applicable to wide types. The method provided by the invention has a wide application potential in other fields needing gas to react.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Heavy oil hydrogenation process

ActiveCN114437779AReduce viscosityImprove liquidityTreatment with hydrotreatment processesBulk chemical productionFluid phaseHydrogenation reaction

The invention discloses a heavy oil hydrogenation process which comprises the following steps: (1) mixing hydrogen and a heavy oil raw material to obtain a first mixed feed; (2) the first mixed feed enters the shell side of the shell-and-tube inorganic membrane tube assembly from the bottom of the fixed bed reactor, and hydrogen is supplemented to enter the tube side to form a second mixed feed; and (3) enabling the second mixed feed to flow upwards into the upper cylinder, alternately carrying out hydrogenation reaction on the inner cylinder and the annular region under the action of a plurality of partition plates axially arranged in the inner cylinder and the annular region, and finally enabling a hydrogenation product to flow out from the upper part. The method solves the problem of large temperature rise in the early reaction stage of the heavy oil liquid phase hydrogenation process, ensures high conversion rate in the middle reaction stage, reduces the later deep cracking reaction, and improves the liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrogenation process of producing hydrogen peroxide by anthraquinone method

ActiveCN104555935BPrevent deficienciesAvoid excessive hydrogenation reactionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGas phaseHydrogenation process

The invention discloses a hydrogenation process for producing a hydrogen peroxide by an anthraquinone method. The hydrogenation process comprises the following steps that: (1) two reactors are arranged in the hydrogenation process for producing the hydrogen peroxide by the anthraquinone method; a first current of fresh hydrogen and a working liquid serve as a feeding material I and perform hydrogenation in the first reactor; the reacted material is subjected to gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the first reactor; the rest of the liquid phase is reasonably optimized and modulated; the phenomenon that the reaction hydrogen is deficient or excessive is avoided; the hydrogenation completeness is realized; the liquid phase and the gas phase are mixed to serve as feeding material II and enter the second reactor; (2) a second current of fresh hydrogen and the feeding material II perform the hydrogenation in the second reactor; the reacted material is subjected to the gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the second reactor, and the rest of the liquid phase enters an oxidation process. According to the process disclosed by the invention, a hydrogenation process is optimized, and meanwhile, side effects are reduced, so that the hydrogenation is more uniform, and the service life of a catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

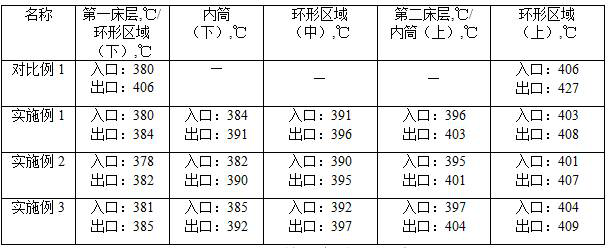

Fixed bed hydrogenation reactor and heavy oil liquid phase hydrogenation process

ActiveCN112705121AReduce viscosityGood dispersionChemical industryTreatment with hydrotreatment processesFluid phaseFixed bed

The invention discloses a fixed bed hydrogenation reactor and a heavy oil liquid phase hydrogenation process, the hydrogenation reactor comprises a reactor outer cylinder body and an inner cylinder, an annular area is arranged between the outer cylinder body and the inner cylinder, the cross sectional area of the inner cylinder is gradually increased from top to bottom, and the cylinder wall of the inner cylinder is uniformly provided with holes communicated with the annular area; the top opening of the inner cylinder is flush with the bottom of a upper seal head of the reactor; the bottom of the inner cylinder is hermetically connected with a lower seal head of the reactor; a shell-and-tube ceramic membrane tube assembly is arranged at the bottom of the inner cylinder, a hydrogen supplementing pipeline is communicated with the ceramic membrane tube, and a liquid phase feeding pipeline is communicated with an in-shell cavity outside the ceramic membrane tube; partition plates are alternately arranged in the inner cylinder and the annular area at different heights; the inner cylinder is filled with a hydrogenation catalyst I, the annular area is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than that of the hydrogenation catalyst II. According to the method, firstly, the heavy oil raw material is subjected to visbreaking treatment, and then the material is alternately subjected to hydrogenation reaction with different active catalysts in the inner barrel and the annular area along the flow channel arranged in the reactor, so that the problems of high activity and large temperature rise in the early stage of reaction can be controlled, and higher conversion rate in the middle stage of reaction is ensured; the deep cracking reaction in the later high-temperature stage of the reaction can be reduced, and the liquid yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for improving yield of bisphenol-A type hydrogenated epoxy resin

The invention discloses a hydrogenation method for improving the yield of a bisphenol-A type hydrogenated epoxy resin. The method comprises a step of uniformly dispersing hydrogen which is input into a hydrogenation reaction tank by using a guidance gas stirrer with aspiration, exhaust and stirring functions in the hydrogenation reaction tank through the aspiration, exhaust and stirring of the guidance gas stirrer. The method ensures that reaction fluid contains high-concentration dissolved hydrogen, so that a hydrogenation catalyst has extremely high activity and the rate of a hydrogenation reaction is accelerated; and the method can ensure that the hydrogenation reaction is performed at low temperature and under low pressure, even increase the yield of the bisphenol-A type hydrogenated epoxy resin to be between 99.0 and 99.9 percent, greatly reduce the construction and maintenance cost of the hydrogenation reaction tank, and improve economic benefit.

Owner:NANYA PLASTICS CORP

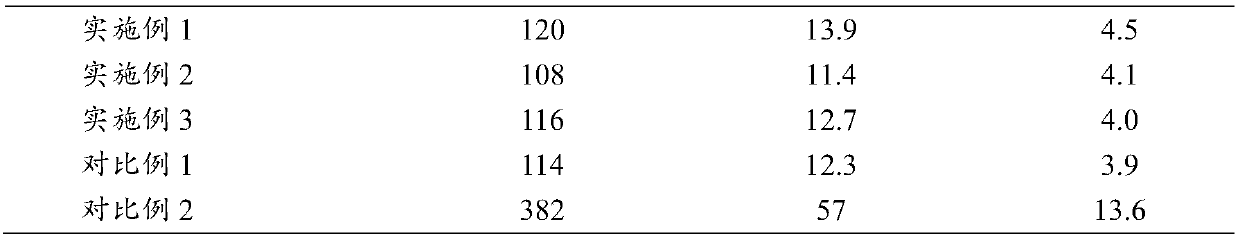

Process and device system for production of dimethyl oxalate by high-pressure carbonylation of industrial synthesis gas and hydrogenation to ethylene glycol

ActiveCN104098441BConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputMethyl carbonateHigh pressure

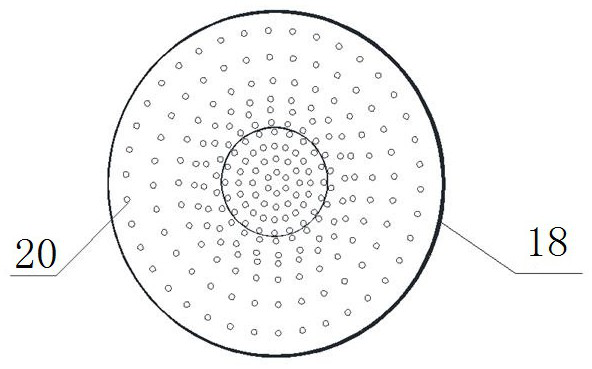

The utility model relates to a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthetic gas and preparing ethylene glycol by hydrogenation. The device system comprises an esterification reaction system, a carbonylation reaction system, a relief gas and waste acid coupled recovery system and a hydrogenation reaction system, wherein the esterification reaction system is used for generating methyl nitrite by reaction; methyl nitrite is treated by the carbonylation reaction system to generate a carbonylation product mainly containing dimethyl oxalate and dimethyl carbonate; the carbonylation product is separated to obtain a dimethyl carbonate, and the rest dimethyl oxalate is treated by the hydrogenation reaction system to generate an ethylene glycol product; waste acid in the esterification reaction and relief gas in the carbonylation reaction are recycled by the relief gas and waste acid coupled recovery system. The device system has the characteristic that the energy consumption is remarkably reduced; the effect is remarkable in combination with the application of the useful substance recycling step, particularly high coupling of waste nitric acid and relief gas recycling as well as recycling of hydrogen in waste gas during separation and reaction.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Method for preparing cyclohexane carboxylic ester from benzene polycarboxylic ester

ActiveCN102153469BImprove contact efficiencyLow operating pressureOrganic compound preparationCarboxylic acid esters preparationBenzeneHydrogenation reaction

The invention relates to a method for preparing cyclohexane carboxylic ester from benzene polycarboxylic ester, aiming at improving a hydrogenation method of the benzene polycarboxylic ester. In the method, the benzene polycarboxylic ester is hydrogenated to form cyclohexane polycarboxylic ester by utilizing a reaction groove provided with a guidance air stirrer having an air extracting and discharging capability in the presence of a hydrogenation catalyst. The preparation method has the advantages that the operation pressure for hydrogenating the benzene polycarboxylic ester is reduced to the minimum, the hydrogenation reaction temperature is greatly reduced, and the yield obtained by hydrogenating the benzene polycarboxylic ester into the cyclohexane polycarboxylic ester is effectively improved.

Owner:NANYA PLASTICS CORP

Direct coal liquefaction oil hydrogenation stabilization method

ActiveCN104927897ASmall scaleLow stress levelRefining to eliminate hetero atomsEnvironmental geologyFixed bed

The present invention provides a direct coal liquefaction oil hydrogenation stabilization method which is as follows: hydrogen is fed by pores with a nano-sized average pore size into the direct coal liquefaction oil to obtain hydrogen-containing liquefied oil; and the hydrogen-containing liquefied oil is fed into a tubular fixed bed reactor in the upward-flow manner for contacting with a hydrogenation catalyst under liquid-phase hydrogenation conditions. Better hydrotreating results can be obtained, the direct coal liquefaction oil sulfur and nitrogen content and residual carbon content can be effectively reduced, polycyclic aromatic hydrocarbons in the direct coal liquefaction oil are partially hydrogenated, and gelatin and asphaltene content in the direct coal liquefaction oil can be reduced. The method needs no hydrogen cycle, the size of a hydrogenation reactor is reduced, the pressure rating of the gas-liquid separation unit is reduced, and investment costs and operating energy consumption are reduced. In addition, a hydrogenation raw material can carry a sufficient amount of hydrogen without introduction of diluent oil and / or circulating oil into the hydrogenation raw material, and the effective capacity of the hydrogenation reactor can be improved.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Method for reducing aromatic hydrocarbon by indirect hydrogen transfer

InactiveCN102408291AIncrease the rate of the hydrogenation reactionMild conditions for hydrogenation reactionHydrocarbon by hydrogenationAlkaneReaction temperature

The invention discloses a method for reducing aromatic hydrocarbon by indirect hydrogen transfer. The aromatic hydrocarbon is reduced into hydrocarbon alkyl in the presence of catalyst, hydrogen transfer medium and hydrogen; and the reduction reaction conditions are as follows: dose ratio of the catalyst to the aromatic hydrocarbon is 0.11-1g / 0.05mol; dose ratio of the hydrogen transfer medium to the aromatic hydrocarbon is 0.005-0.05mol / 0.05mol; hydrogen is filled to 0.2-0.4MPa; reaction temperature is 50-180 degrees centigrade; and the reaction time is 1-7h. The method for reducing aromatic hydrocarbon disclosed by the invention is convenient to operate and high-efficiency.

Owner:ZHEJIANG UNIV

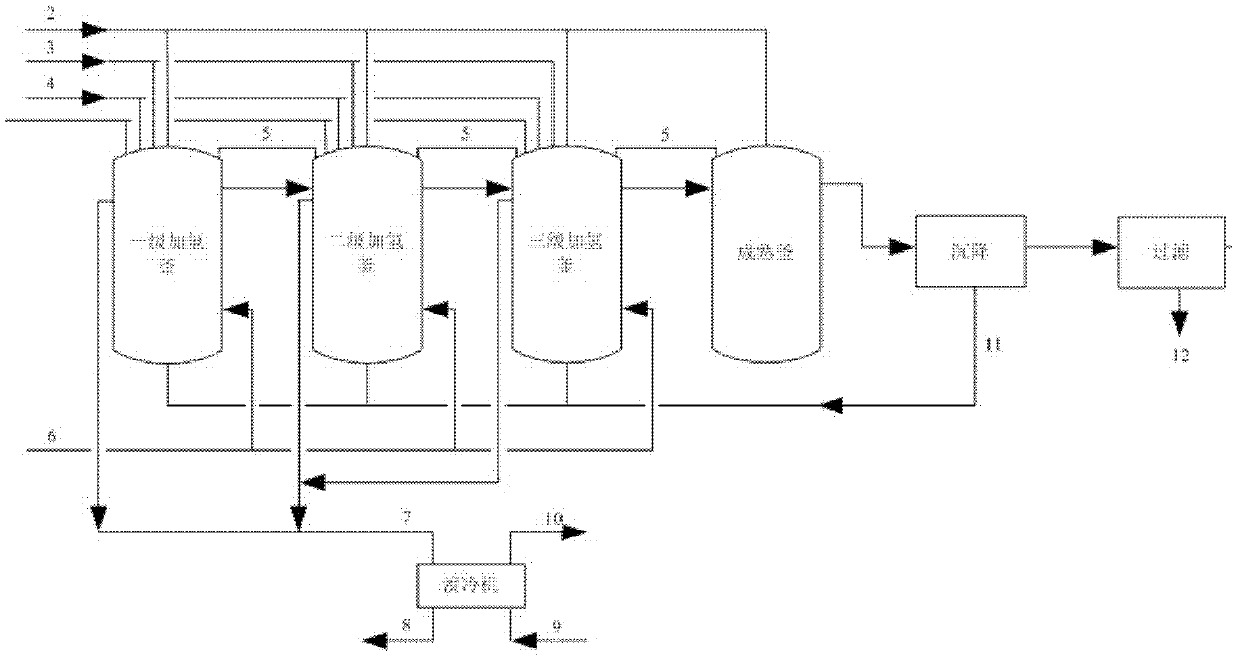

Method for continuous hydrogenation of dinitrobenzene and recycling of reaction heat thereof

ActiveCN103360265BProcess stabilityImprove efficiencyOrganic compound preparationChemical recyclingHydrogenation reactionCooling fluid

The invention provides a method for continuous hydrogenation of dinitrobenzene and recycling of reaction heat thereof. The method comprises the following steps: (1) adopting a plurality of stages of hydrogenation reaction kettles which are connected in series, continuously leading the materials dinitrobenzene and methanol to a first stage of a hydrogenation reaction kettle, and simultaneously leading in hydrogen continuously and adding a catalyst, carrying out a liquid-phase catalytic hydrogenation reaction, and continuously feeding the material from the final stage of hydrogenation reaction kettle to a mature kettle to cure and cool; meanwhile, removing hydrogenation reaction heat by water, so as to obtain hot water of 105-120 DEG C; and (2) orderly carrying out continuous sedimentation, filtering and separation on hydrogenation reduction cooling fluid from the mature kettle, and then recovering and mechanically applying the separated catalyst in cycle, and carrying out dealcoholization, dehydration and rectification on the separated hydrogenation reduction fluid to obtain diaminobenzene. Thus, effective utilization of reaction heat energy is achieved on the premise of efficiently producing the diaminobenzene; the aim of saving energy is achieved.

Owner:ZHEJIANG HONGSHENG CHEM IND +1

A kind of fixed bed hydrogenation reactor and heavy oil liquid phase hydrogenation process

ActiveCN112705121BReduce viscosityGood dispersionChemical industryTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses a fixed-bed hydrogenation reactor and a heavy oil liquid-phase hydrogenation process. The hydrogenation reactor comprises an outer cylinder and an inner cylinder of the reactor, an annular area is formed between the outer cylinder and the inner cylinder, and the transverse direction of the inner cylinder is The cross-sectional area gradually increases from top to bottom, the inner cylinder wall is evenly opened and connected to the annular area, the top opening of the inner cylinder is flush with the bottom of the upper head of the reactor, and the bottom of the inner cylinder is tightly connected with the lower head of the reactor; A shell-and-tube ceramic membrane tube assembly is arranged at the bottom, the hydrogen supplementation pipeline is communicated with the ceramic membrane tube, and the liquid-phase feed pipeline is communicated with the inner cavity of the shell outside the ceramic membrane tube; the inner tube and the annular area are alternately arranged with baffles at different heights; The cylinder is filled with hydrogenation catalyst I, the annular region is filled with hydrogenation catalyst II, and the activity of hydrogenation catalyst I is higher than that of hydrogenation catalyst II. The method of the invention firstly performs viscosity reduction treatment on the heavy oil raw material, and then makes the material undergo hydrogenation reaction with different active catalysts alternately in the inner cylinder and the annular area along the flow channel arranged in the reactor, that is, the high activity and temperature rise in the early stage of the reaction can be controlled. It is a big problem, ensuring a high conversion rate in the middle of the reaction, reducing the deep cracking reaction in the high-temperature stage in the later stage of the reaction, and improving the liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrogenation conversion method

ActiveCN102417826BLow investment costEasy to manufacture and installHydrocarbon oil crackingHydrogenLiquid hydrocarbons

A heavy oil hydrogenation conversion method. Under a condition of a heavy oil hydrogenation conversion reaction, a heavy oil raw material mixture containing heavy oil raw materials and a catalyst is allowed to contact hydrogen in a tubular reactor, and heavy oil macromolecules are converted into gas and liquid hydrocarbon reaction products, wherein the contact between hydrogen and the heavy oil raw material mixture is performed at least twice. The invention adopts a tubular reaction which has a small diameter and is simple in manufacturing and installation; by means of multi-time hydrogen injection, the invention reduces the hydrogen excessive amount during the reaction, and improves the utilization rates of hydrogen and the reactor. The heavy oil direct hydrogenation conversion method provided by the invention can improve the efficiency of heavy oil direct hydrogenation conversion, thus reduces cost for heavy oil hydrogenation conversion, and improves the technical economy of heavy oil hydrogenation conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for stabilizing coal direct liquefied oil by hydrogenation

ActiveCN104927897BLow asphaltene contentReduce contentRefining to eliminate hetero atomsNano sizeOperating energy

The invention provides a method for stabilizing hydrogenation of direct coal liquefied oil, which comprises sending hydrogen gas into the direct coal liquefied oil through pores with an average pore diameter of nanometer size to obtain hydrogen-containing liquefied oil; flowing the hydrogen-containing liquefied oil upwards It is sent into a tubular fixed-bed reactor by means of a liquid-phase hydrotreating condition to contact with a hydrogenation catalyst. This method can obtain better hydrogenation treatment effect, effectively reduce the content of sulfur and nitrogen and residual carbon in the direct coal liquefaction oil, partially hydrogenate the polycyclic aromatic hydrocarbons in the direct coal liquefaction oil, and reduce the colloid and asphaltene content. Moreover, the method does not need to circulate hydrogen, reduces the scale of the hydrogenation reaction device, reduces the pressure level of the gas-liquid separation device, and reduces the investment cost and operating energy consumption of the hydrogenation device. In addition, the method can make the hydrogenation raw material carry a sufficient amount of hydrogen without introducing diluent oil and / or cycle oil into the hydrogenation raw material, and improves the effective processing capacity of the hydrogenation reaction device.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Method for reducing aromatic hydrocarbon by indirect hydrogen transfer

InactiveCN102408291BIncrease the rate of the hydrogenation reactionMild conditions for hydrogenation reactionHydrocarbon by hydrogenationAlkaneReaction temperature

The invention discloses a method for reducing aromatic hydrocarbon by indirect hydrogen transfer. The aromatic hydrocarbon is reduced into hydrocarbon alkyl in the presence of catalyst, hydrogen transfer medium and hydrogen; and the reduction reaction conditions are as follows: dose ratio of the catalyst to the aromatic hydrocarbon is 0.11-1g / 0.05mol; dose ratio of the hydrogen transfer medium to the aromatic hydrocarbon is 0.005-0.05mol / 0.05mol; hydrogen is filled to 0.2-0.4MPa; reaction temperature is 50-180 degrees centigrade; and the reaction time is 1-7h. The method for reducing aromatic hydrocarbon disclosed by the invention is convenient to operate and high-efficiency.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com