Multi-phase catalytic hydrogenation reduction method of unsaturated compound

A heterogeneous catalysis and unsaturated technology, used in chemical instruments and methods, preparation of organic compounds, preparation of amino compounds, etc., can solve the problems of slow reaction and less research, reduce requirements and risks, increase hydrogen concentration, The effect of increasing the hydrogenation reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

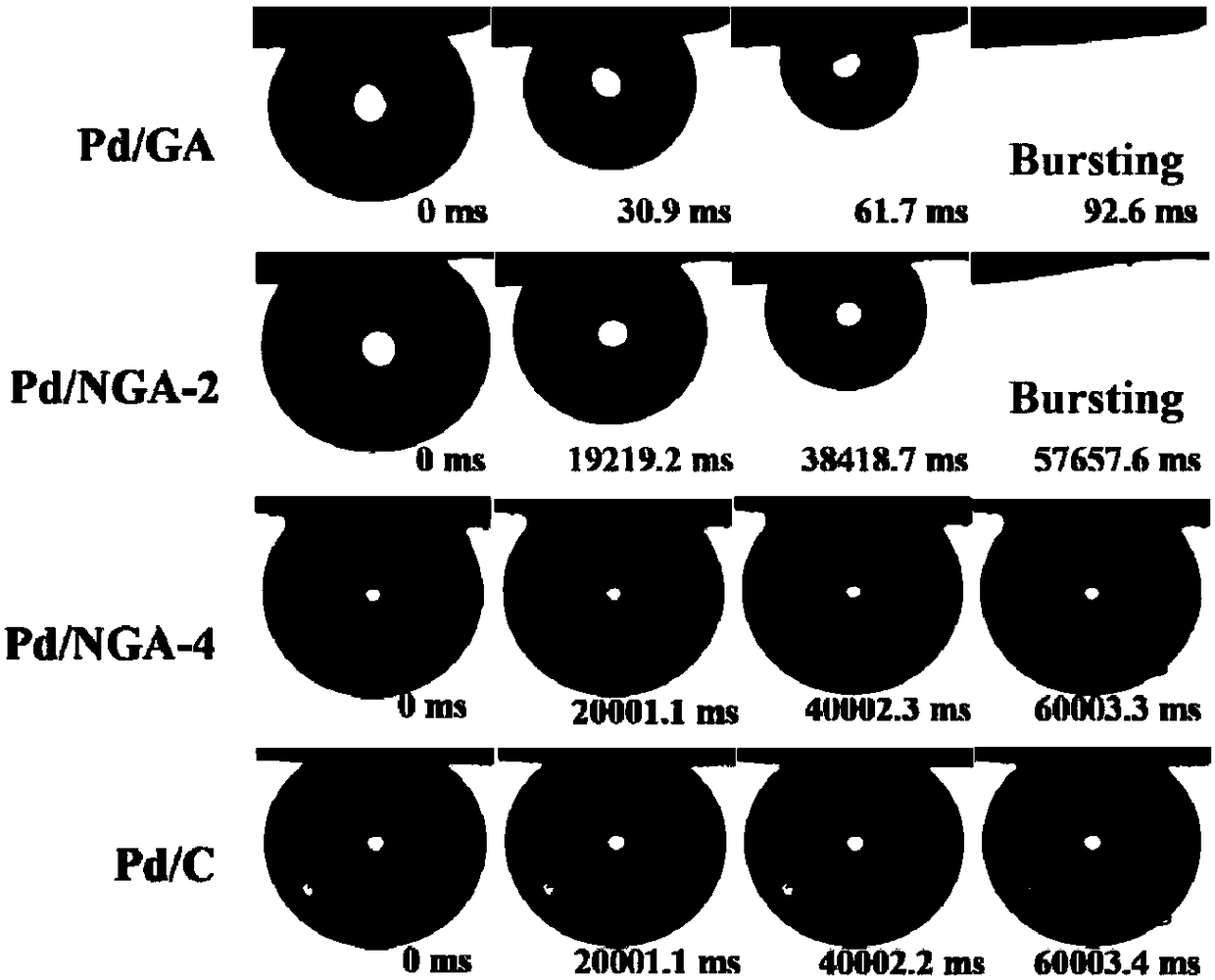

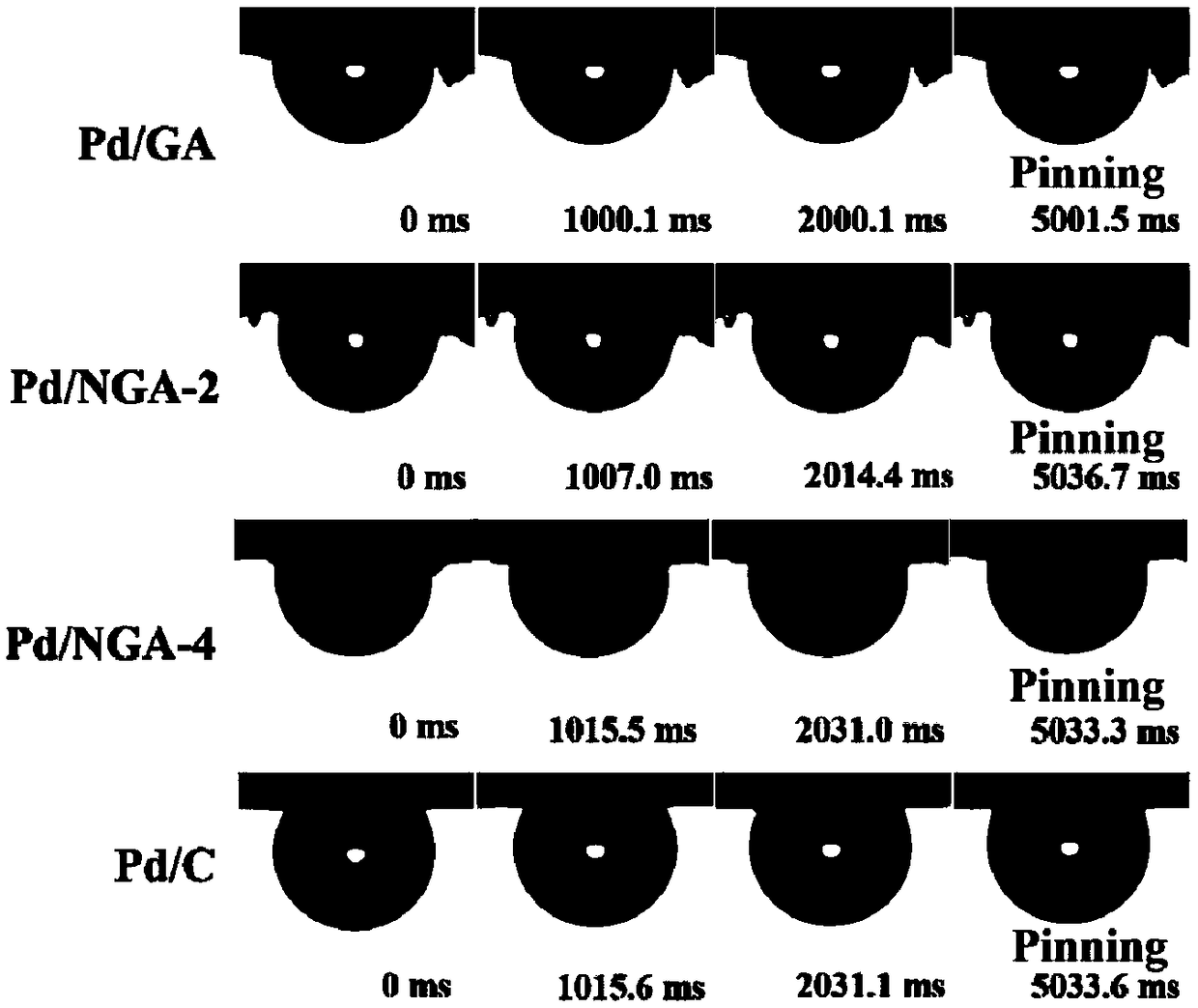

[0034] Example 1, Hydrophobic and aerophilic catalyst Pd / GA and a series of comparative catalysts Pd / NGA-2, Pd / NGA-4, commercial Pd / C adsorption behavior of hydrogen in liquid

[0035] 1. Preparation of aerophilic catalyst palladium / graphene airgel Pd / GA

[0036] (1) Preparation of carrier GA: Mix 5 mL of graphene oxide aqueous solution (1 mg / mL) with 5 mL of water, add 0.5 g of KI and 0.5 mL of concentrated hydrochloric acid, and react in an oven at 80 ° C for 8 hours to obtain a hydrogel. The obtained hydrogel was soaked in water for 3 days, during which the water was changed every 12 h, and the graphene airgel GA was obtained by freeze-drying. Under Ar atmosphere, burn GA at 140°C for one hour to remove I 2 , and then raised to 800 ° C for 2 hours to remove other impurities.

[0037] (2) Loaded palladium: Measure the sodium chloropalladate solution according to the theoretical load of 3.8wt%, add 2mL of absolute ethanol to the sodium chloropalladate solution (0.0564mol / L)...

Embodiment 2

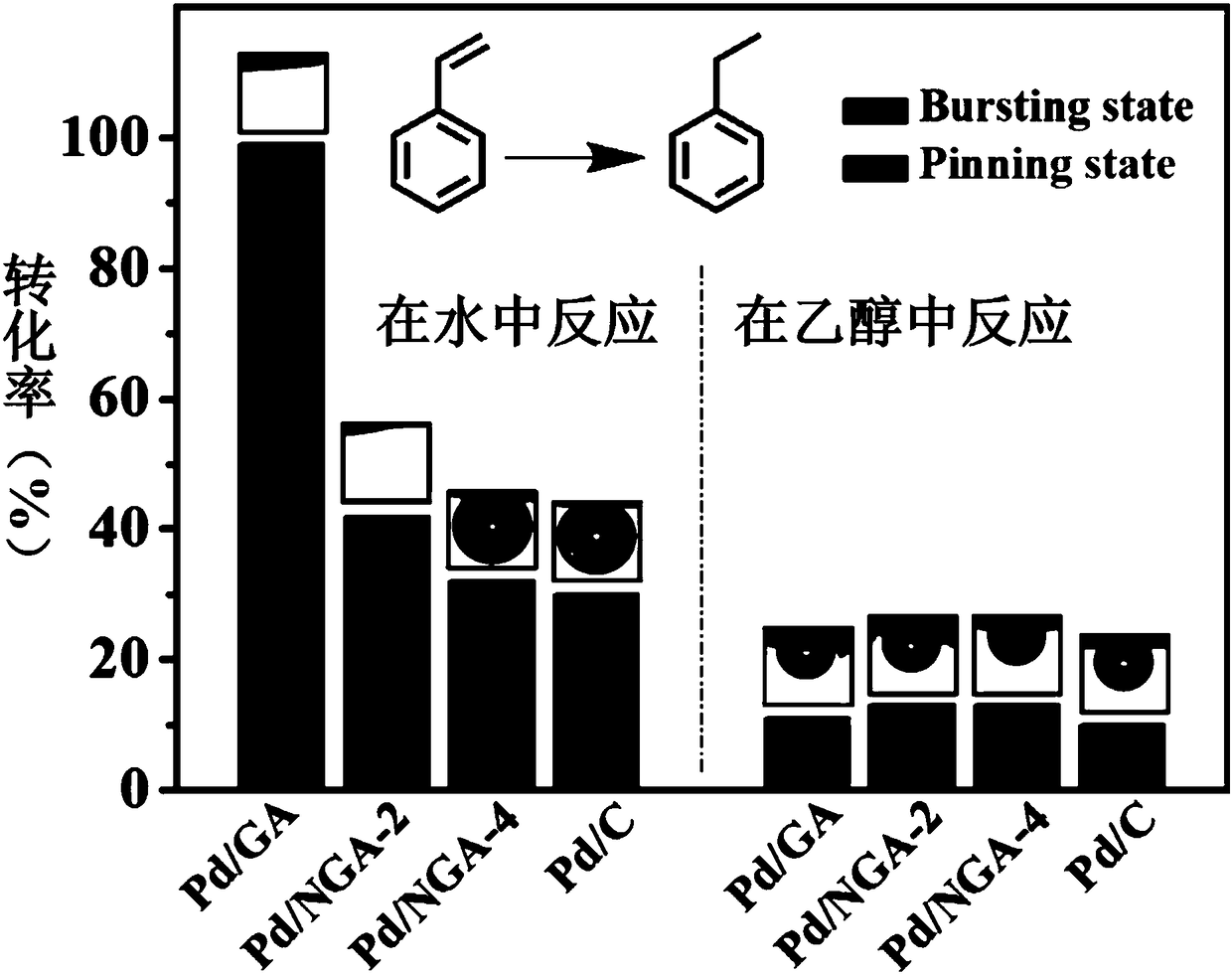

[0046] Embodiment 2, heterogeneous catalytic hydrogenation reduction styrene

[0047] According to the following steps for the heterogeneous catalytic hydrogenation reduction of styrene:

[0048]Add Pd / GA (1 mg), styrene (12 μL, 0.1 mmol) and mesitylene (internal standard, 15 μL, 0.1 mmol) into 4 mL of solvent (water or ethanol), bubble hydrogen, and react at 35 ° C for 40 min. After the reaction, it was extracted with ethyl acetate, and the organic phase was analyzed by GC. Comparative catalyst addition: Pd / NGA-2 (0.7mg), Pd / NGA-4 (0.5mg), Pd / C (0.1mg).

[0049] Experimental results such as image 3 As shown, when the solvent is water, when Pd / GA is used as a catalyst to catalyze the hydrogenation of styrene, the conversion rate is close to 100%.

Embodiment 3

[0050] Embodiment 3, heterogeneous catalytic hydrogenation reduction nitro compound

[0051] According to the following steps heterogeneous catalytic hydrogenation reduction nitro compound:

[0052] Pd / GA (2 mg), substrate (0.1 mmol) and n-tridecane (internal standard, 12 μL, 0.05 mmol) were added to 4 mL of water, hydrogen was bubbled, and reacted at a certain temperature for a certain period of time. After the reaction, it was extracted with ethyl acetate, and the organic phase was analyzed by GC. Comparative catalyst addition amount: Pd / NGA-4 (1 mg), Pd / C (0.18 mg). The reaction conditions and conversion rates of different substrates (nitro compounds) are shown in Table 1.

[0053] Table 1. Performance comparison of catalysts for nitro hydrogenation

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com