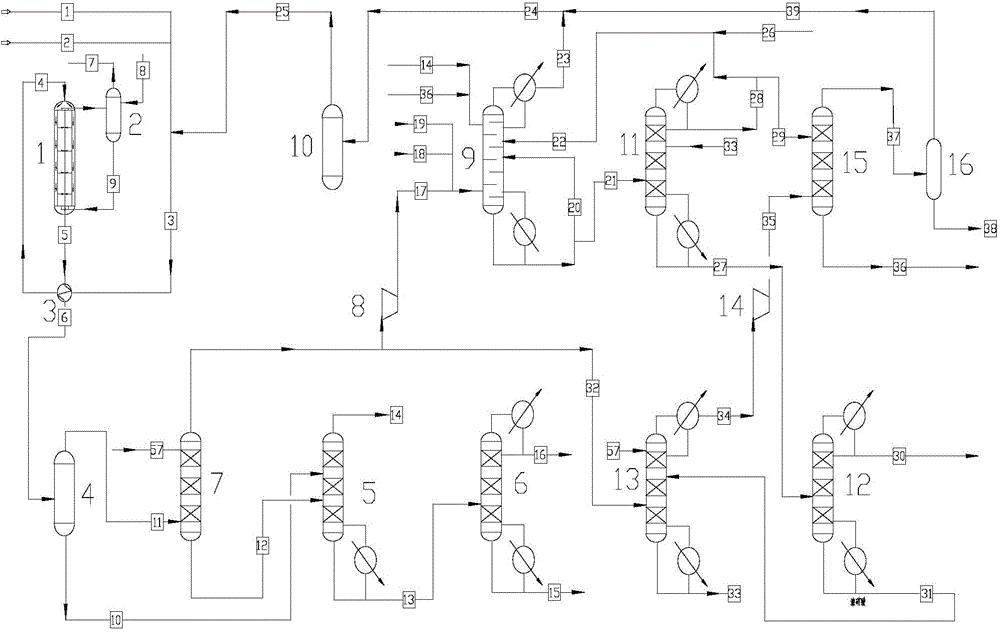

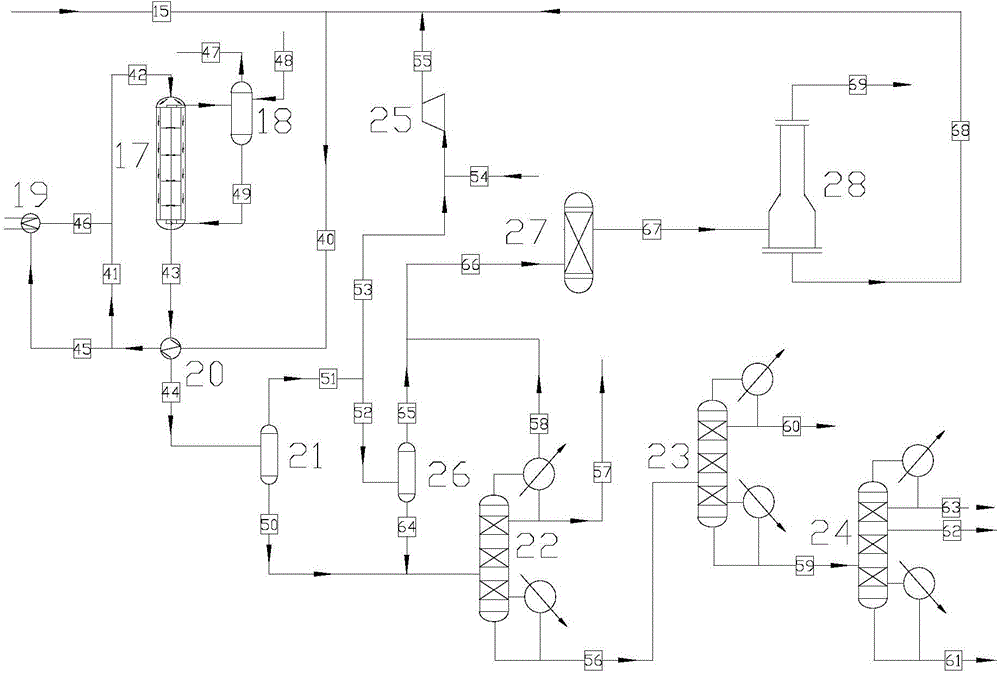

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

A technology of dimethyl oxalate and high-pressure carbonylation, which is applied in the preparation of nitrite, carbon monoxide or formate reaction preparation, chemical instruments and methods, etc., can solve the problems of large equipment investment, low catalyst utilization rate and high system consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0145] As a preferred embodiment, the esterification reaction tower 9 is a packed tower;

[0146] As a more preferred embodiment, the esterification reaction tower 9 is a tray-packing mixed tower having a tray part and a packing part.

[0147] As a preferred embodiment, the methanol washing tower 7, the methanol rectifying tower 5, the methanol recovery tower 11, the NO recovery tower 13, the MN recovery tower 15, the DMO rectification tower 6 and the nitric acid concentration tower 12 are packed towers, Tray column or bubble cap column.

[0148] As a preferred embodiment, the packing packed in the packed tower is random packing or high-efficiency structured packing; the shape of the random packing is saddle shape, Raschig ring, Pall ring, wheel shape, rectangular saddle Ring, spherical or columnar; the high-efficiency structured packing is corrugated packing, grid packing, pulse packing. .

[0149] The hydrogenation plate reactor 17 can be a plate reactor, a tubular reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com