Anti-oxidization water cooling device and method for high-temperature easily-oxidized powder

A water-cooling device and easy-to-oxidize technology, applied in the field of water-cooling devices, can solve the problems of anti-oxidative cooling, easy powder agglomeration, water vapor accumulation, etc., and achieve the effects of reducing inner wall wear, reducing deposition, and simplifying subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

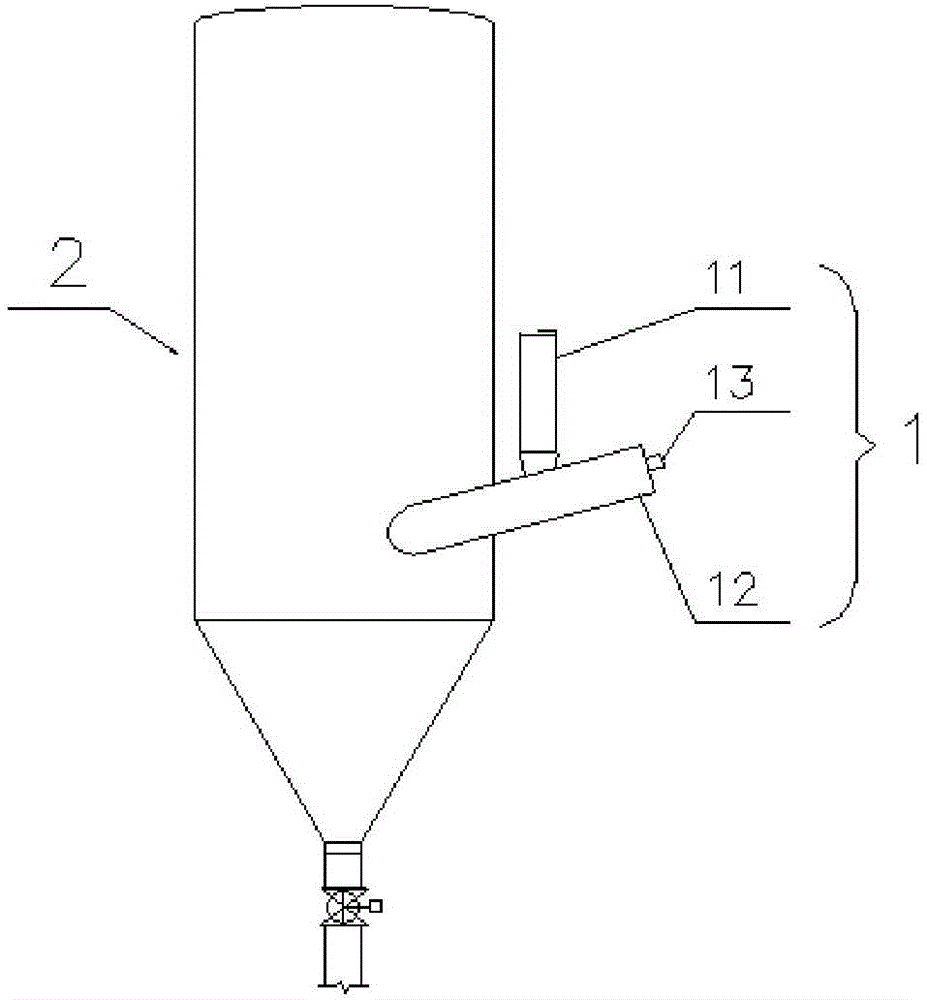

[0044] see figure 1 , this embodiment provides an anti-oxidation water cooling device for high-temperature easily oxidizable powder, including a powder dispersing conveying device 1 and a cooling tower body 2; the powder dispersing conveying device 1 includes a feeding pipe 11, a dispersing conveying pipe 12 and nozzle 13; one end of the dispersing delivery pipe 12 communicates with the cooling tower body 2, and the other end of the dispersing delivery pipe 12 is provided with a nozzle 13; the dispersing delivery pipe 12 communicates with the feeding pipe 11 to form a three-way structure.

[0045] The high-temperature easily oxidizable powder enters the dispersing conveying pipe through the feeding pipe, meets the cooling water sprayed from the nozzle installed at one end of the dispersing conveying pipe, and is cooled by water quenching. The cooling water will disperse the high-temperature powder falling into the dispersing conveying pipe to form a mixed flow of water and pow...

Embodiment 2

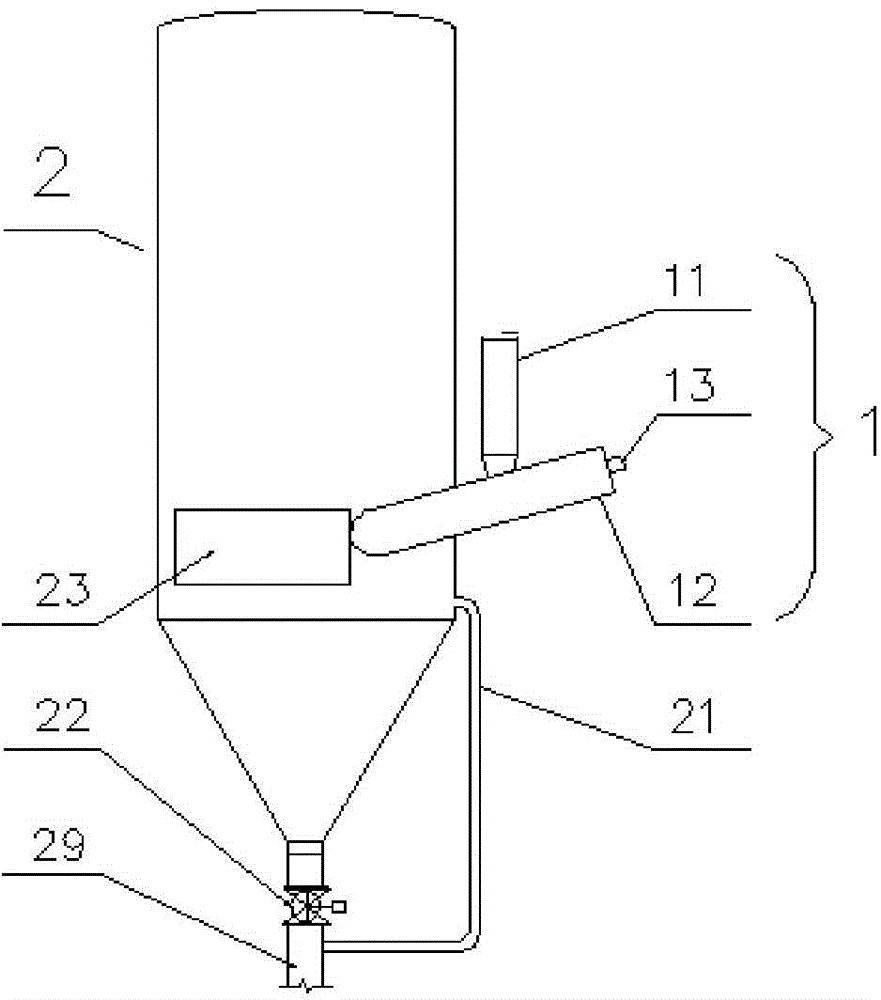

[0047] see figure 2, this embodiment provides an anti-oxidation water cooling device for high-temperature easily oxidizable powder, including a powder dispersing conveying device 1 and a cooling tower body 2; the powder dispersing conveying device 1 includes a feeding pipe 11, a dispersing conveying pipe 12 and nozzle 13; one end of the dispersing delivery pipe 12 communicates with the cooling tower body 2 in a tangential manner (making the mixed flow of water and powder form a swirling flow on the inner wall of the cooling tower, see Figure 5 ), and lower than the other end provided with a nozzle 13; the angle between the dispersing delivery pipe 12 and the horizontal axis of the cooling tower body 2 is 15°, and the cooling tower impacted by the mixed flow of water and powder in the dispersing delivery pipe The inner wall area of the body 2 is provided with a wear-resistant lining plate 23; the dispersing conveying pipe 12 is connected with the feeding pipe 11 to form a t...

Embodiment 3

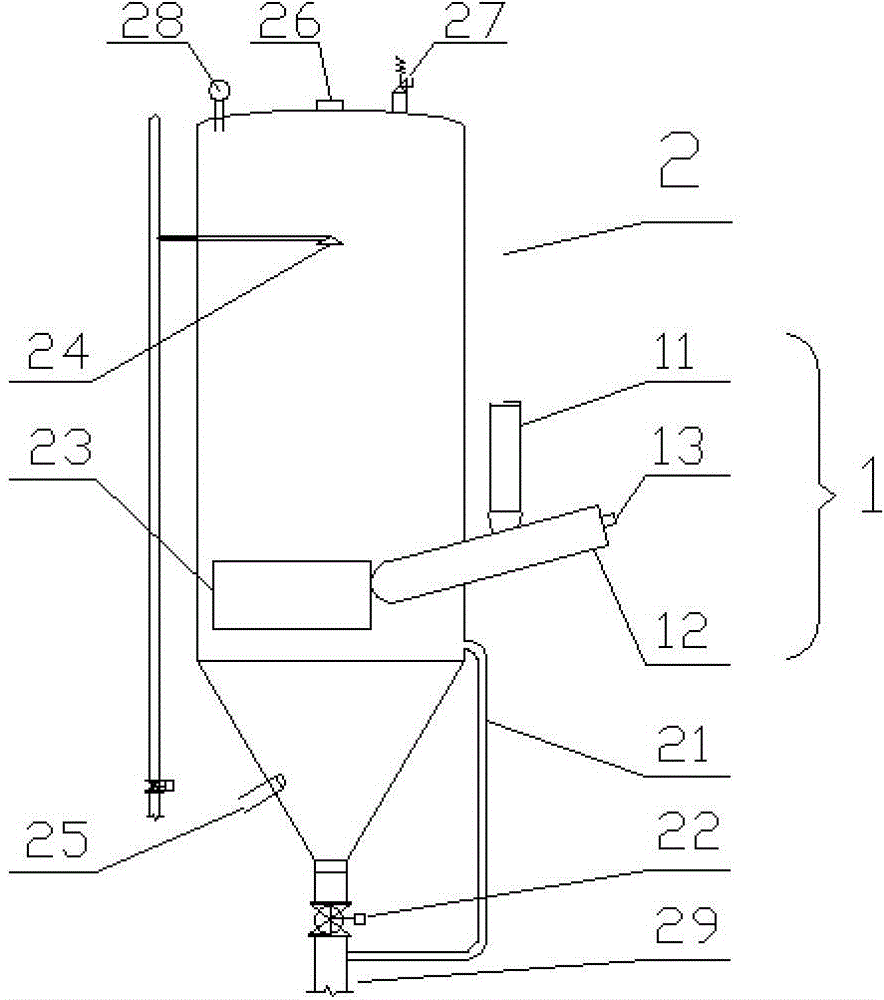

[0049] see image 3 , this embodiment provides an anti-oxidation water cooling device for high-temperature easily oxidizable powder, including a powder dispersing conveying device 1 and a cooling tower body 2; the powder dispersing conveying device 1 includes a feeding pipe 11 and a dispersing conveying pipe 12. One end of the dispersing delivery pipe 12 communicates with the cooling tower body 2 in a tangential form, and is lower than the other end provided with three nozzles 13, and the clamping between the dispersing delivery pipe 12 and the horizontal axis of the cooling tower body 2 The angle is 5°, and the inner wall area of the cooling tower body 2 impacted by the mixed flow of water and powder in the dispersing conveying pipe 12 is provided with a wear-resistant lining plate 23; the dispersing conveying pipe 12 is connected with the feeding pipe 11 to form a three-way Structure; the cooling tower body 2 is made up of the cylindrical portion of the top and the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com