A kind of highly dispersed non-precious metal catalyst and its preparation method and application

A non-precious metal and catalyst technology, which is applied in the field of preparation of highly dispersed supported catalysts, can solve the problems of high active component loading, high active center dispersion, and other problems, and achieve the effects of small restrictions, wide application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

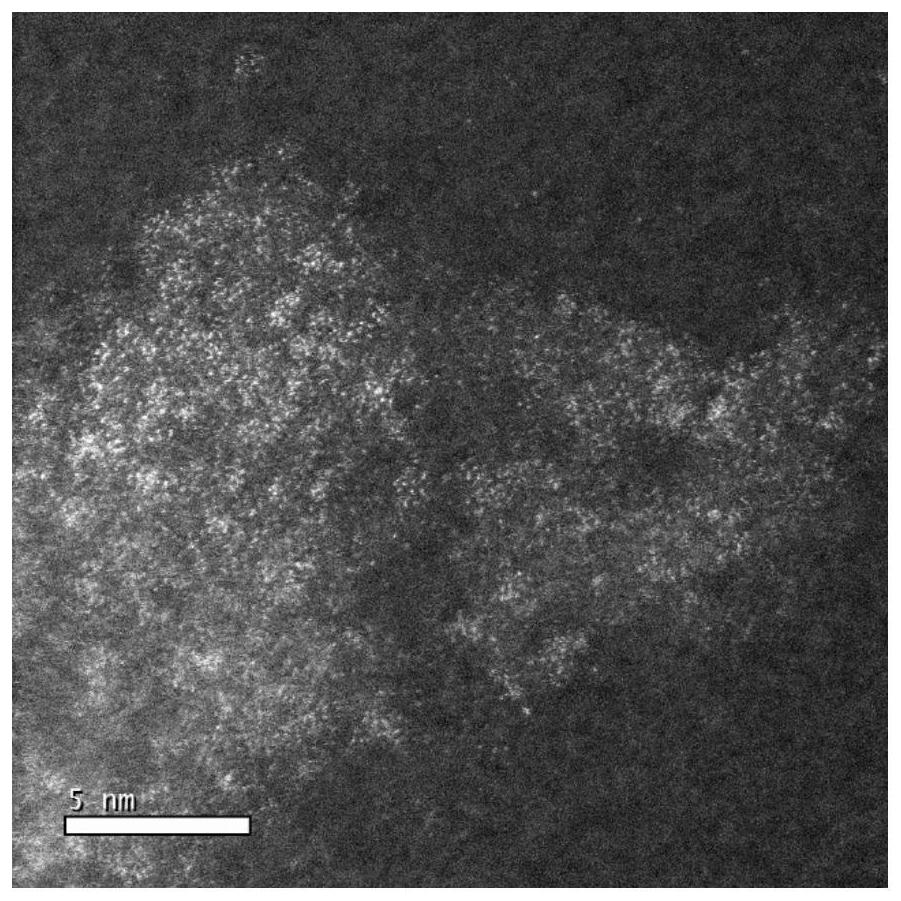

Image

Examples

preparation example Construction

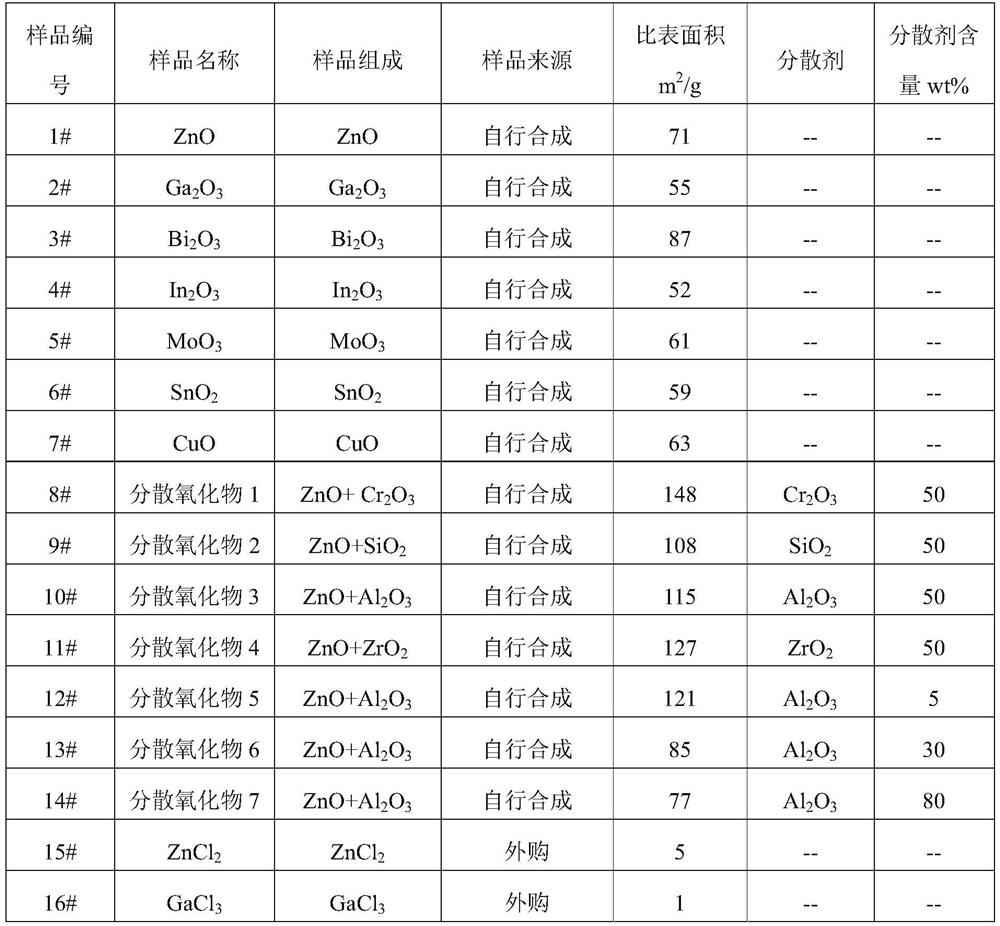

[0049] 1. Preparation of active component precursors

[0050] (1) Synthesis of ZnO materials by precipitation method:

[0051] (1) Weigh 0.446g (1.5mmol) Zn(NO 3 ) 2 ·6H 2 O in a container, weighed 0.480g (12mmol) and added to the above container, then weighed 30ml of deionized water and added to the above container, stirred at 70°C for more than 0.5h to make the solution evenly mixed, and naturally cooled to room temperature. The reaction solution was centrifuged to collect the precipitate after centrifugation, and washed twice with deionized water to obtain the ZnO metal oxide precursor;

[0052] (2) Roasting: After the above-mentioned obtained product is dried in the air, it is calcined in the atmosphere to obtain a ZnO material with a high specific surface area. The atmosphere is inert gas, reducing gas or oxidizing gas; the inert gas is N 2 One or more of , He and Ar; the reducing gas is H 2 One or two of CO, reducing gas can also contain inert gas; oxidizing gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com