Process and device system for production of dimethyl oxalate by high-pressure carbonylation of industrial synthesis gas and hydrogenation to ethylene glycol

A dimethyl oxalate, medium and high pressure technology, used in the preparation of nitrite, carbon monoxide or formate reaction preparation, chemical instruments and methods, etc., can solve the problem that a single series of equipment cannot be adapted, high system consumption, and low catalyst utilization And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

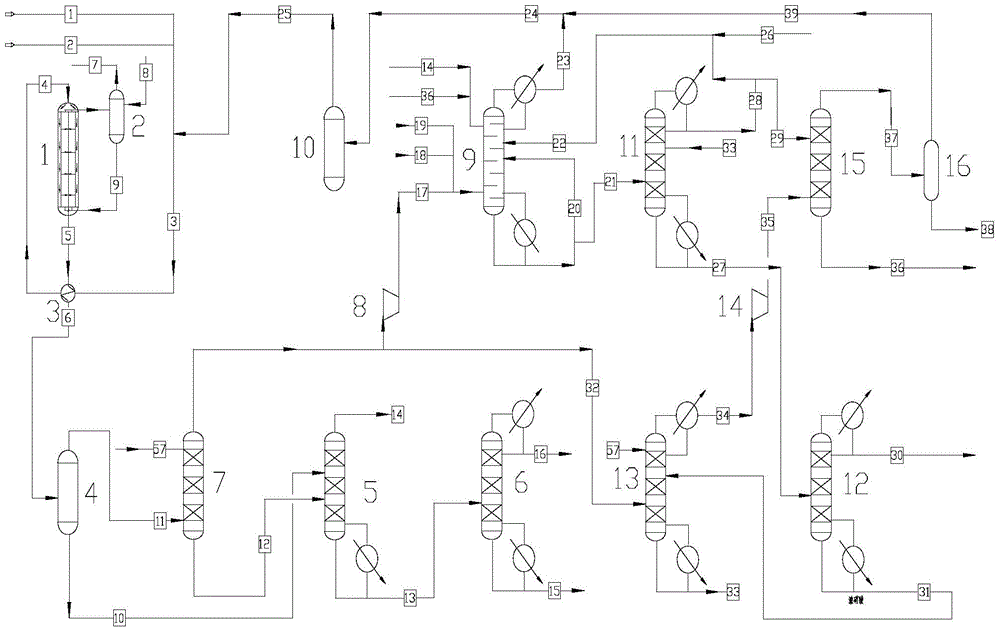

[0145] As a preferred embodiment, the esterification reaction tower 9 is a packed tower;

[0146] As a more preferred embodiment, the esterification reaction tower 9 is a tray-packing mixed tower having both a tray part and a packing part.

[0147] As a preferred embodiment, the methanol washing column 7, methanol rectification column 5, methanol recovery column 11, NO recovery column 13, MN recovery column 15, DMO rectification column 6 and nitric acid concentration column 12 are packed columns, Tray or bubble column.

[0148] As a preferred embodiment, the packing packed in the packed tower is random packing or high-efficiency structured packing; the shape of the random packing is saddle shape, Raschig ring, Pall ring, wheel shape, rectangular saddle Ring, spherical or columnar; the high-efficiency structured packing is corrugated packing, grid packing, pulse packing. .

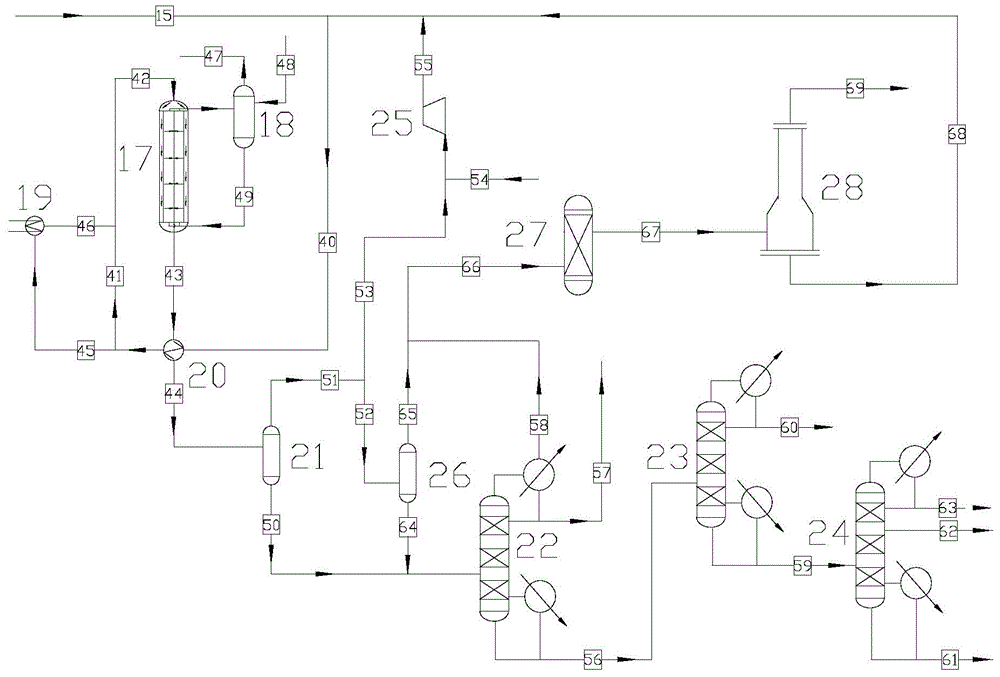

[0149] The hydrogenation plate reactor 17 can be a plate reactor, a tubular reactor or a tubular-plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com