Patents

Literature

65results about How to "Low asphaltene content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

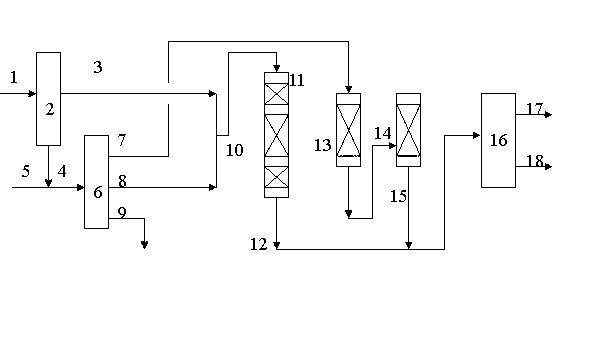

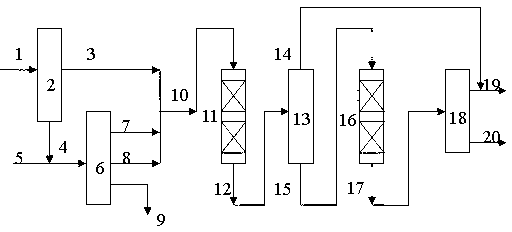

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

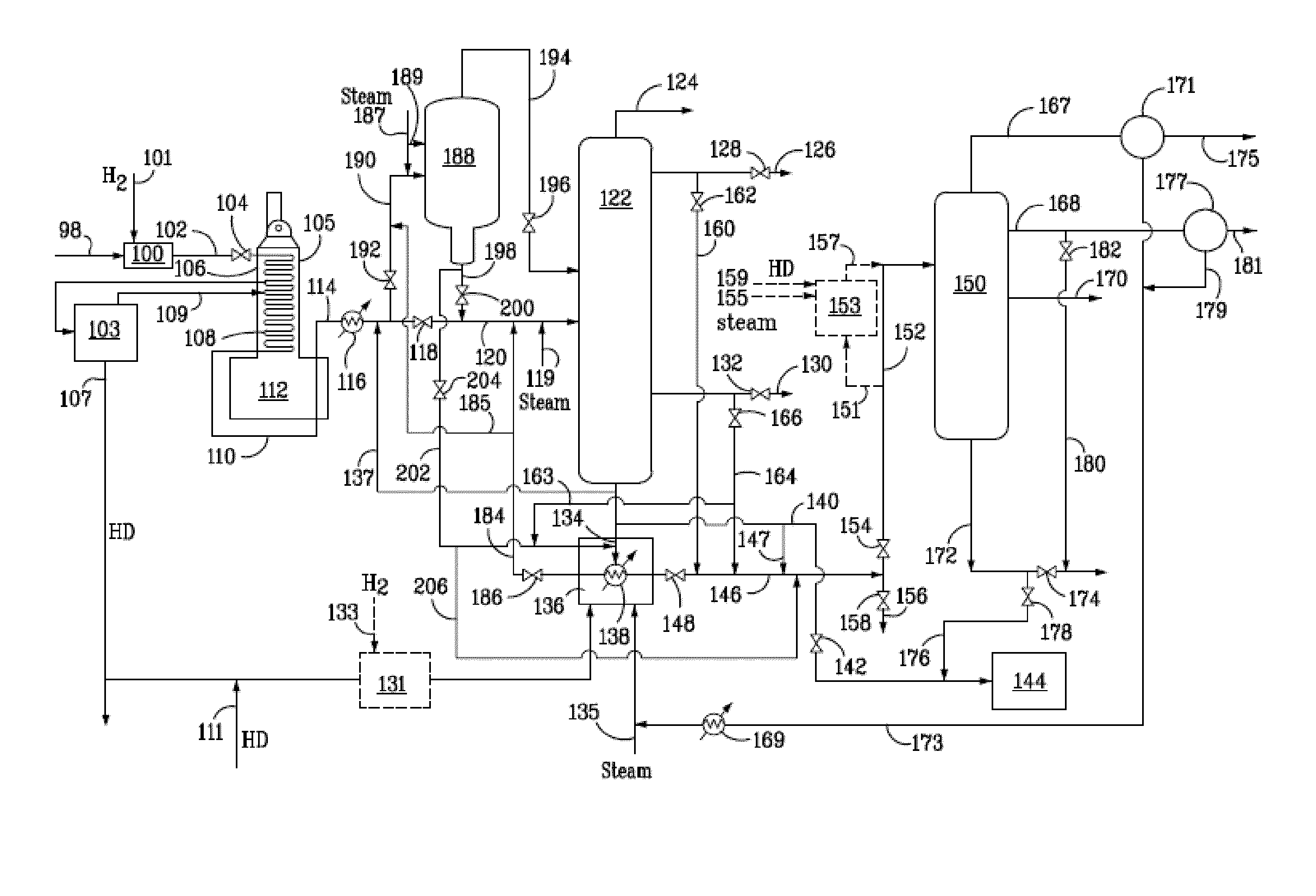

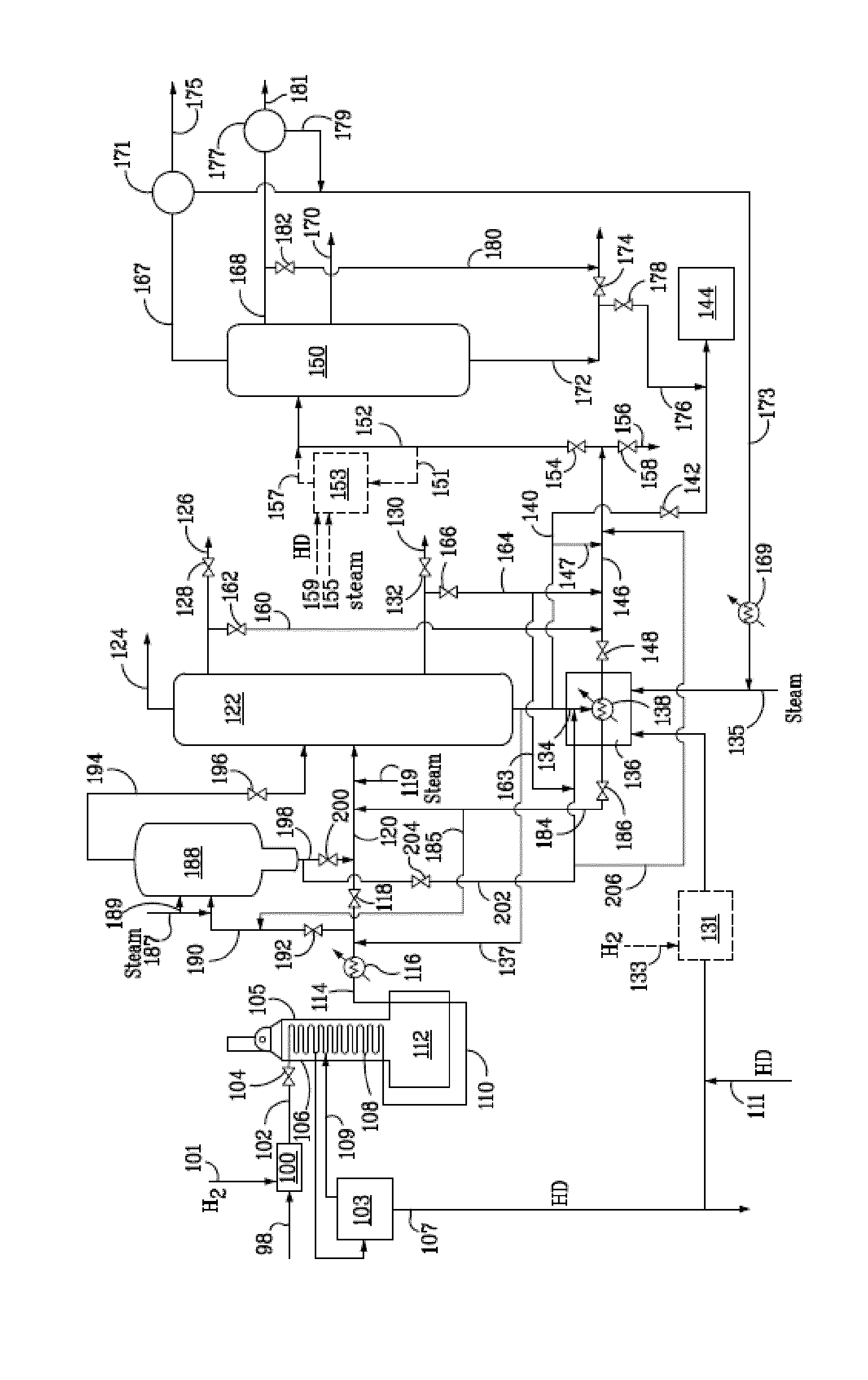

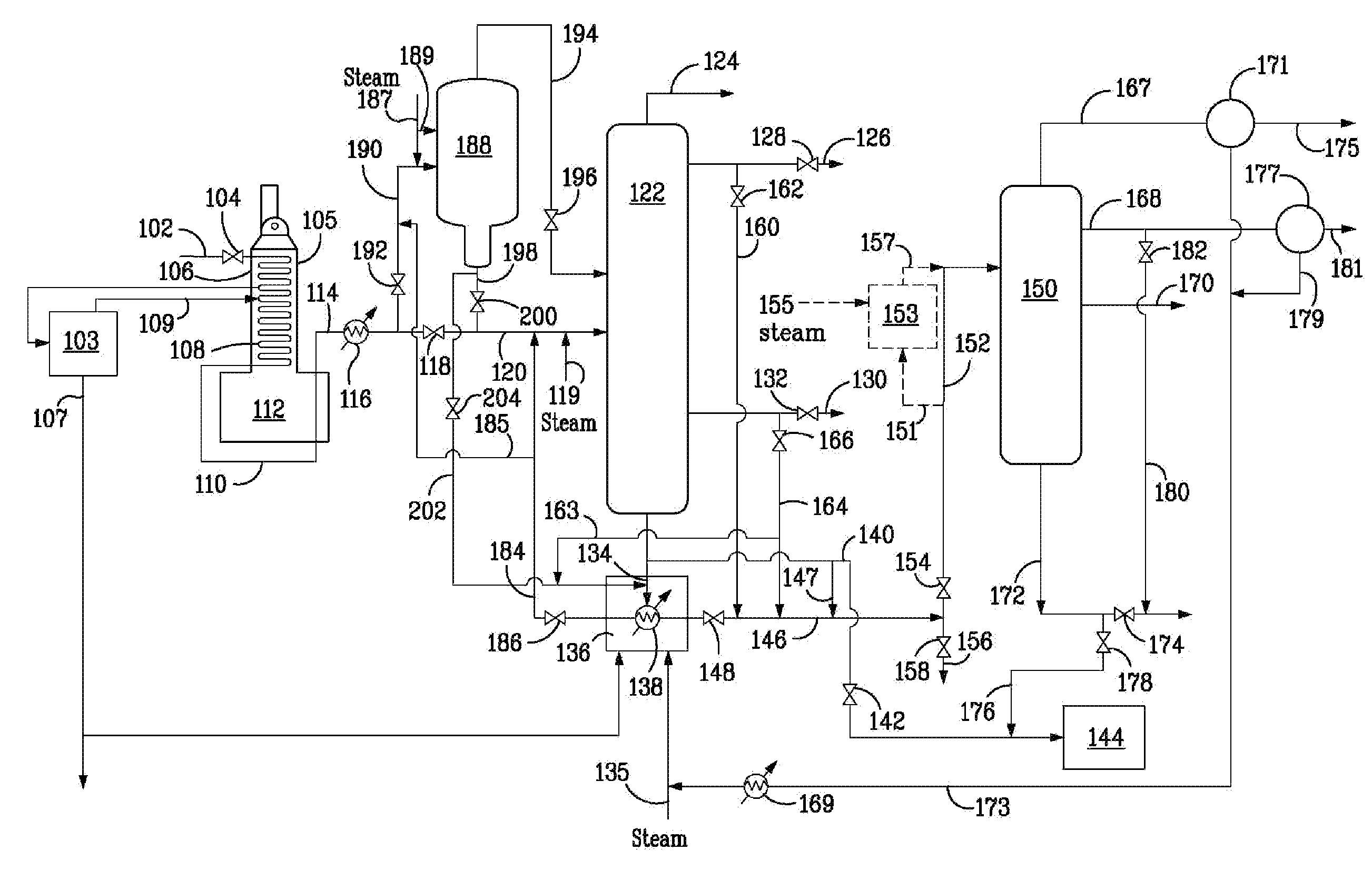

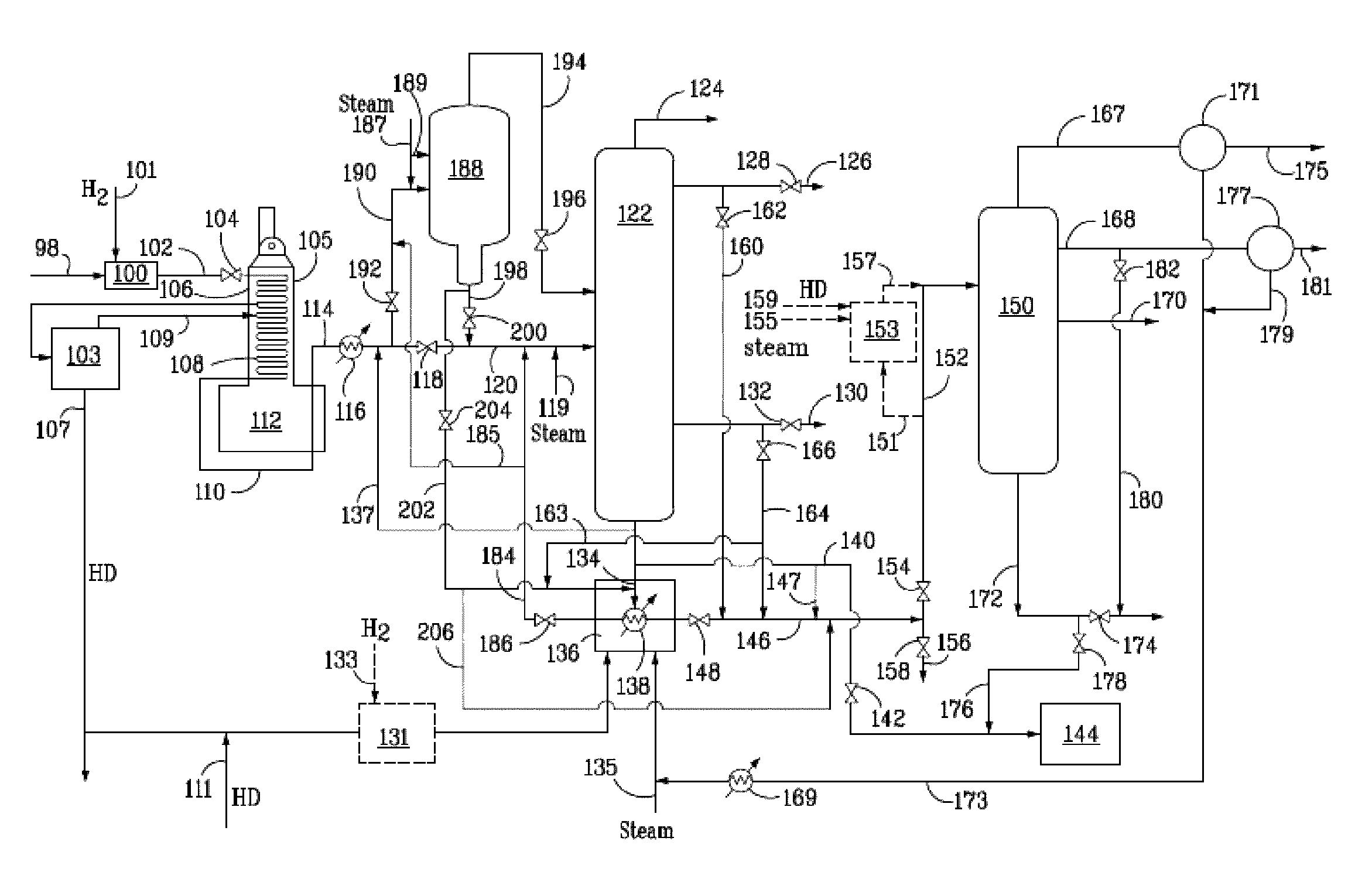

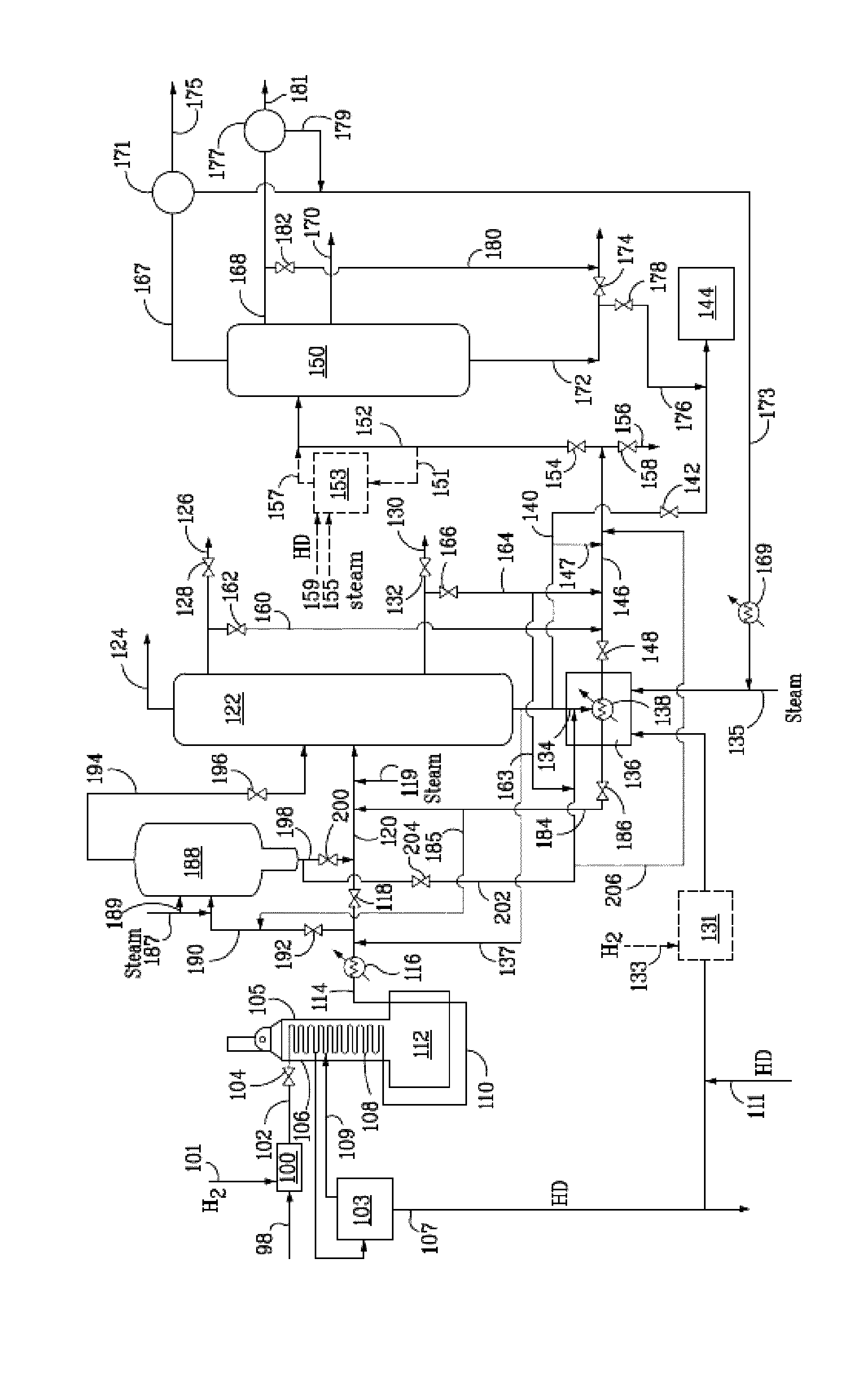

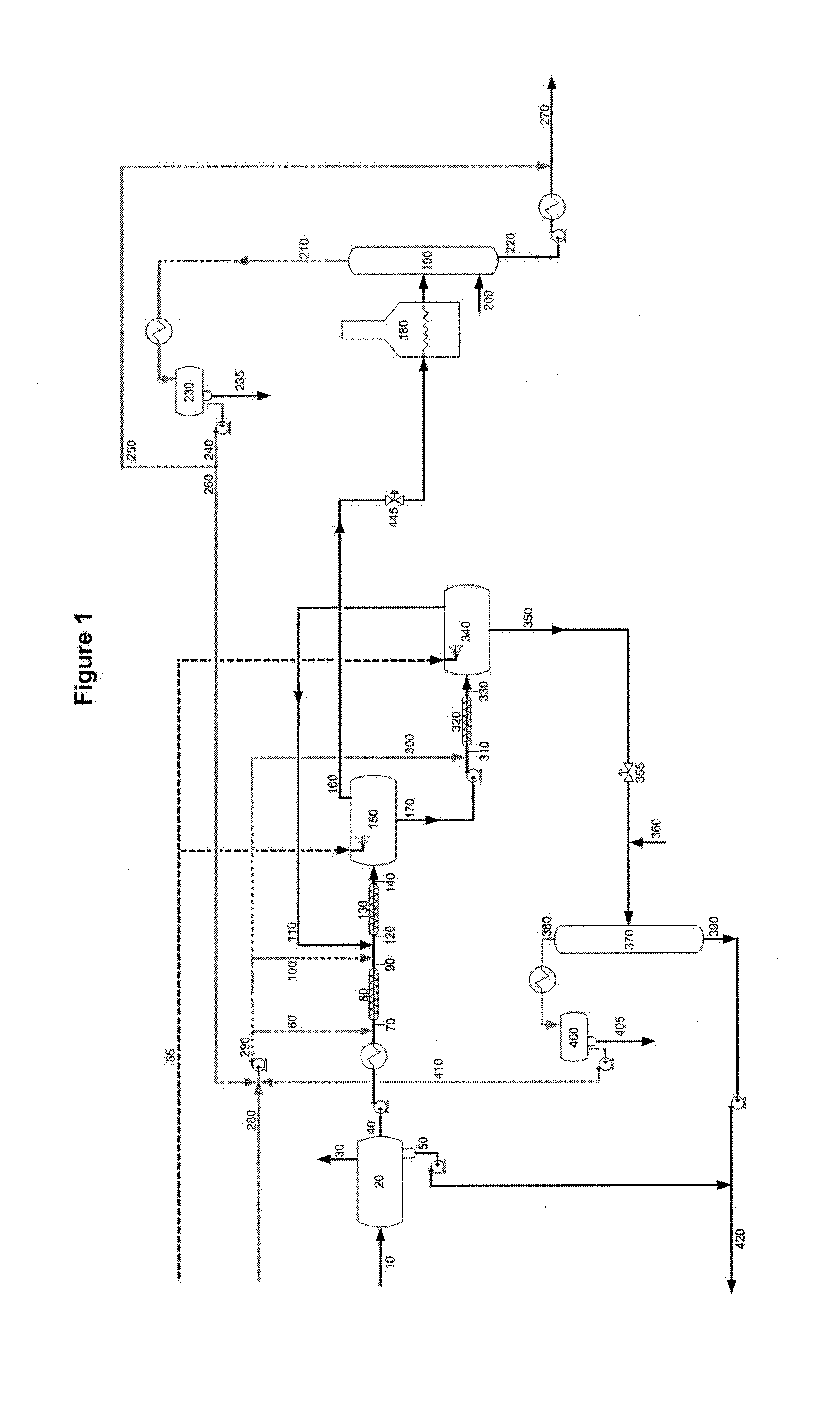

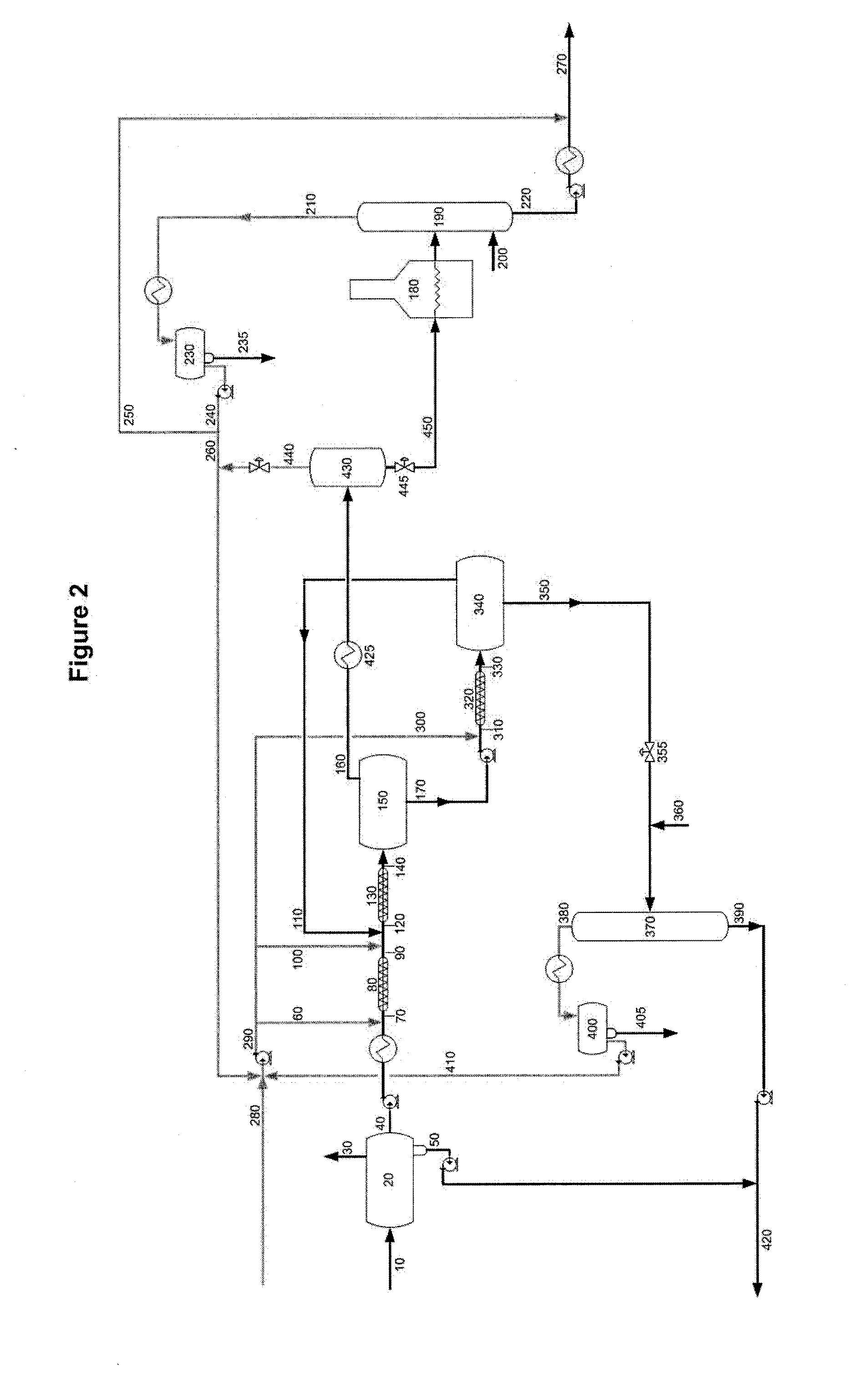

Process and Apparatus for Upgrading Steam Cracker Tar Using Hydrogen Donor Compounds

ActiveUS20110005970A1Efficiently managing introductionSelf containedThermal non-catalytic crackingTreatment with plural serial cracking stages onlyCycle oilTar

A process and apparatus are provided for upgrading steam cracker tars from steam crackers. The invention also relates to a steam cracking process and apparatus for reducing yields of tars produced from steam cracking while increasing yields of higher value products by heating steam cracker tar, in the presence of hydrogen donor compounds, e.g., tetralin. The hydrogen donor compounds can be provided in a hydrogen donor-rich hydrocarbon stream, e.g., light cycle oils, or low sulfur vacuum tower bottoms. The treated tar can be separated into gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

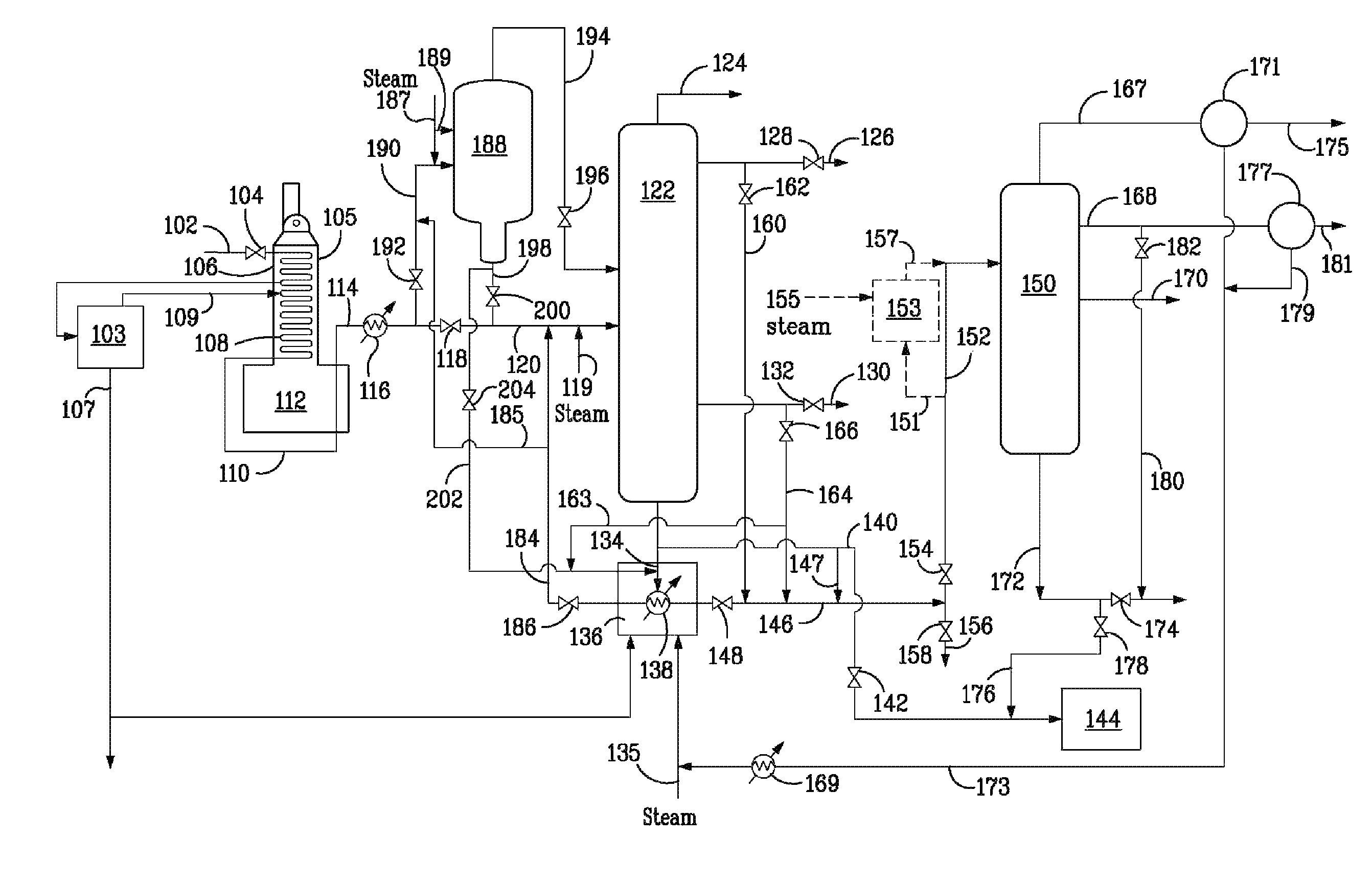

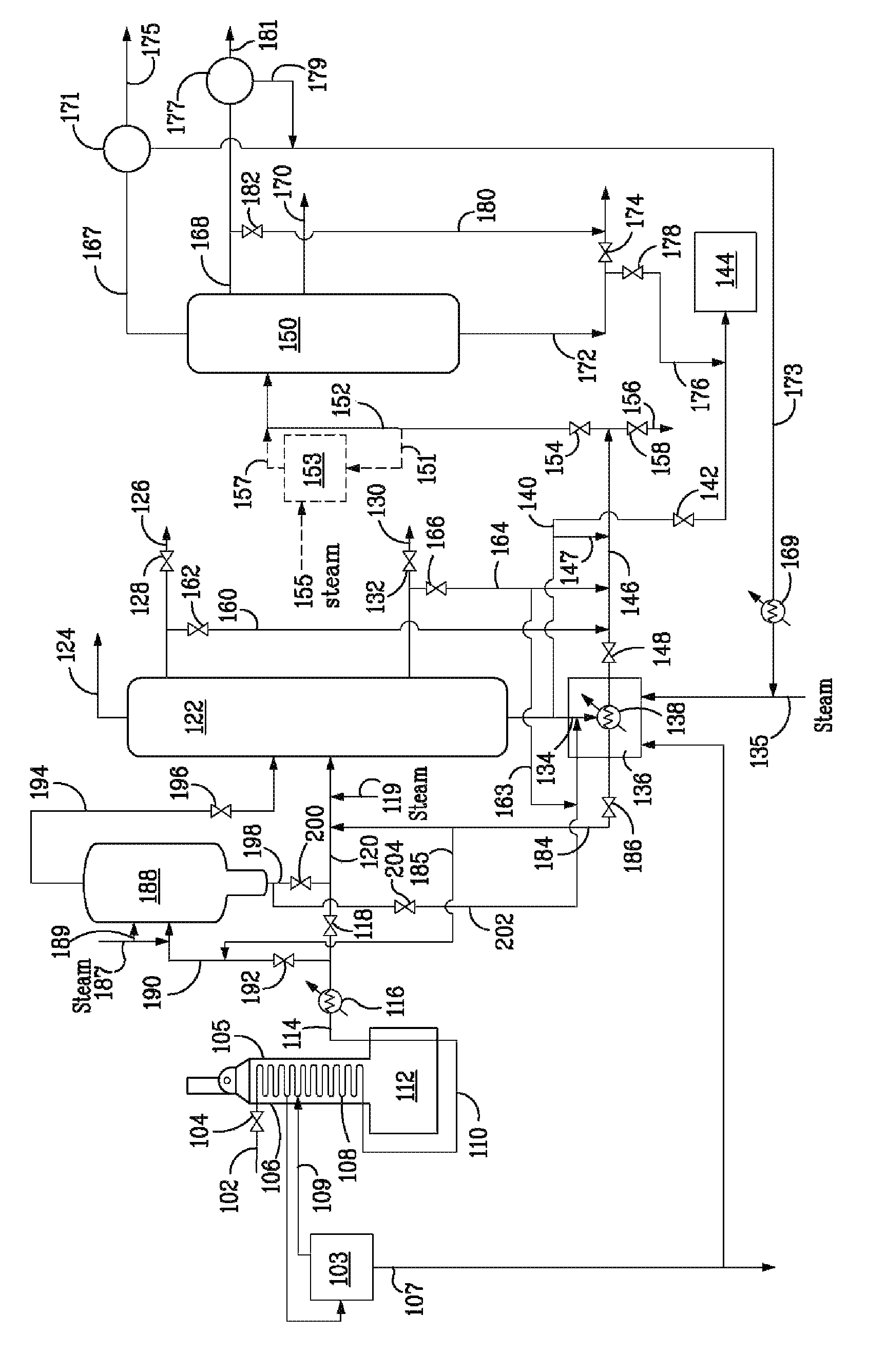

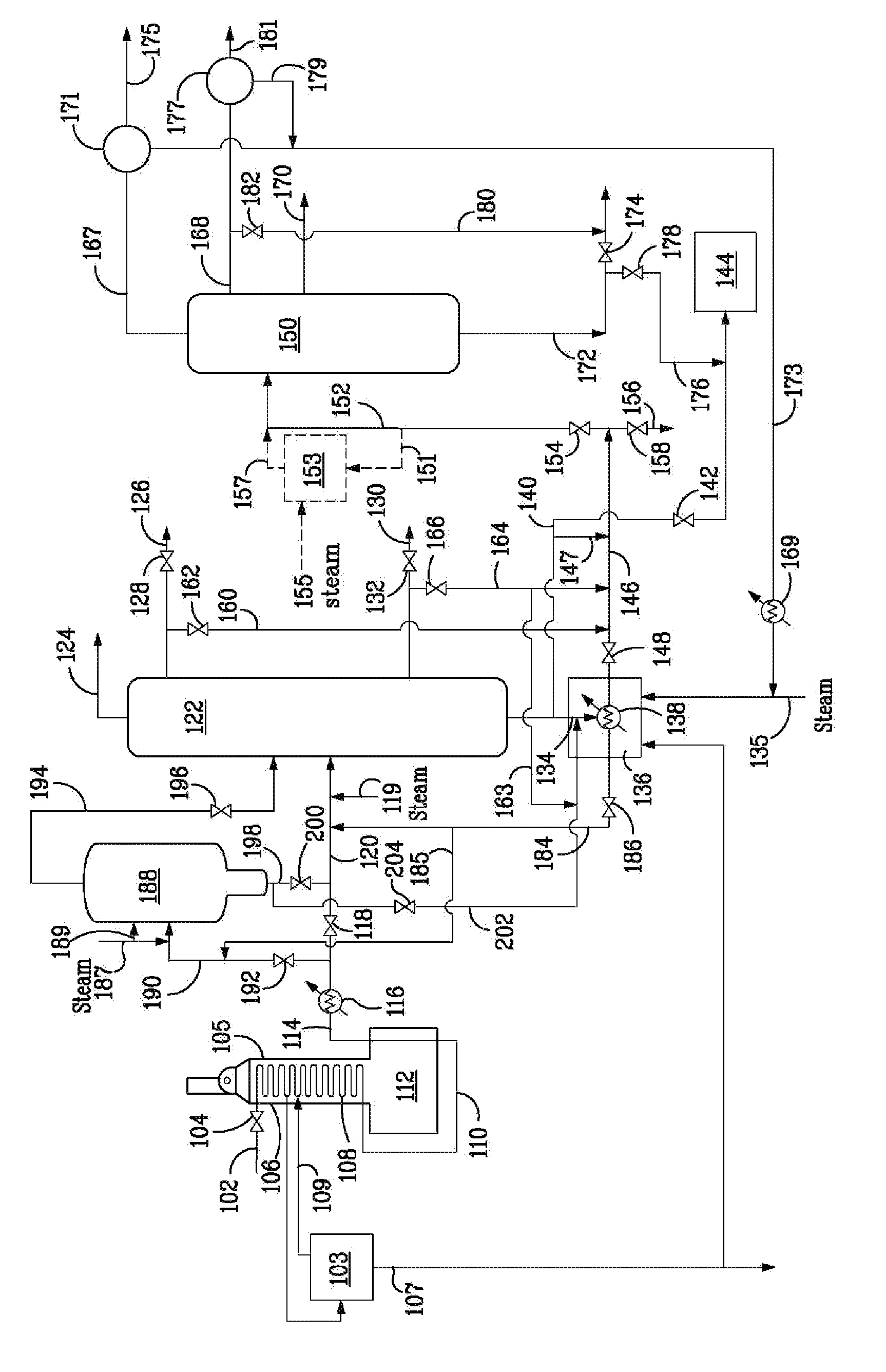

Process and apparatus for upgrading steam cracker tar-containing effluent using steam

ActiveUS8105479B2Increase percentageReduce processThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansVisbreakerFuel oil

A process and apparatus are provided for the present invention relates to a process for upgrading tar-containing effluent from a steam cracker furnace that comprises: a) contacting a steam cracker tar-containing effluent with steam and for a time, sufficient to convert at least a portion of the steam cracker tar to a mixture comprising lower boiling molecules and the steam cracker tar-containing effluent; and b) separating the mixture from step a) into i) at least one tar-lean product; and ii) a tar-rich product having a final boiling above the final boiling point of the at least one tar-lean product. Step a) can includes at least one of: 1) contacting said steam cracker tar-containing effluent with steam added to the effluent in a transfer line downstream of a steam cracker furnace comprising a quench inlet, with the steam added through or downstream of the quench inlet; 2) contacting the steam cracker tar-containing effluent with steam under heat soaking conditions in a heat soaking vessel to which the steam is added; and 3) contacting the steam cracker tar-containing effluent with steam under visbreaking conditions in a visbreaker. The steam treated tar can be separated into higher value gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

Process and Apparatus for Upgrading Steam Cracker Tar-Containing Effluent Using Steam

ActiveUS20100320119A1Self containedIncrease percentageThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansVisbreakerBoiling point

A process and apparatus are provided for the present invention relates to a process for upgrading tar-containing effluent from a steam cracker furnace that comprises: a) contacting a steam cracker tar-containing effluent with steam and for a time, sufficient to convert at least a portion of the steam cracker tar to a mixture comprising lower boiling molecules and the steam cracker tar-containing effluent; and b) separating the mixture from step a) into i) at least one tar-lean product; and ii) a tar-rich product having a final boiling above the final boiling point of the at least one tar-lean product. Step a) can includes at least one of: 1) contacting said steam cracker tar-containing effluent with steam added to the effluent in a transfer line downstream of a steam cracker furnace comprising a quench inlet, with the steam added through or downstream of the quench inlet; 2) contacting the steam cracker tar-containing effluent with steam under heat soaking conditions in a heat soaking vessel to which the steam is added; and 3) contacting the steam cracker tar-containing effluent with steam under visbreaking conditions in a visbreaker. The steam treated tar can be separated into higher value gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

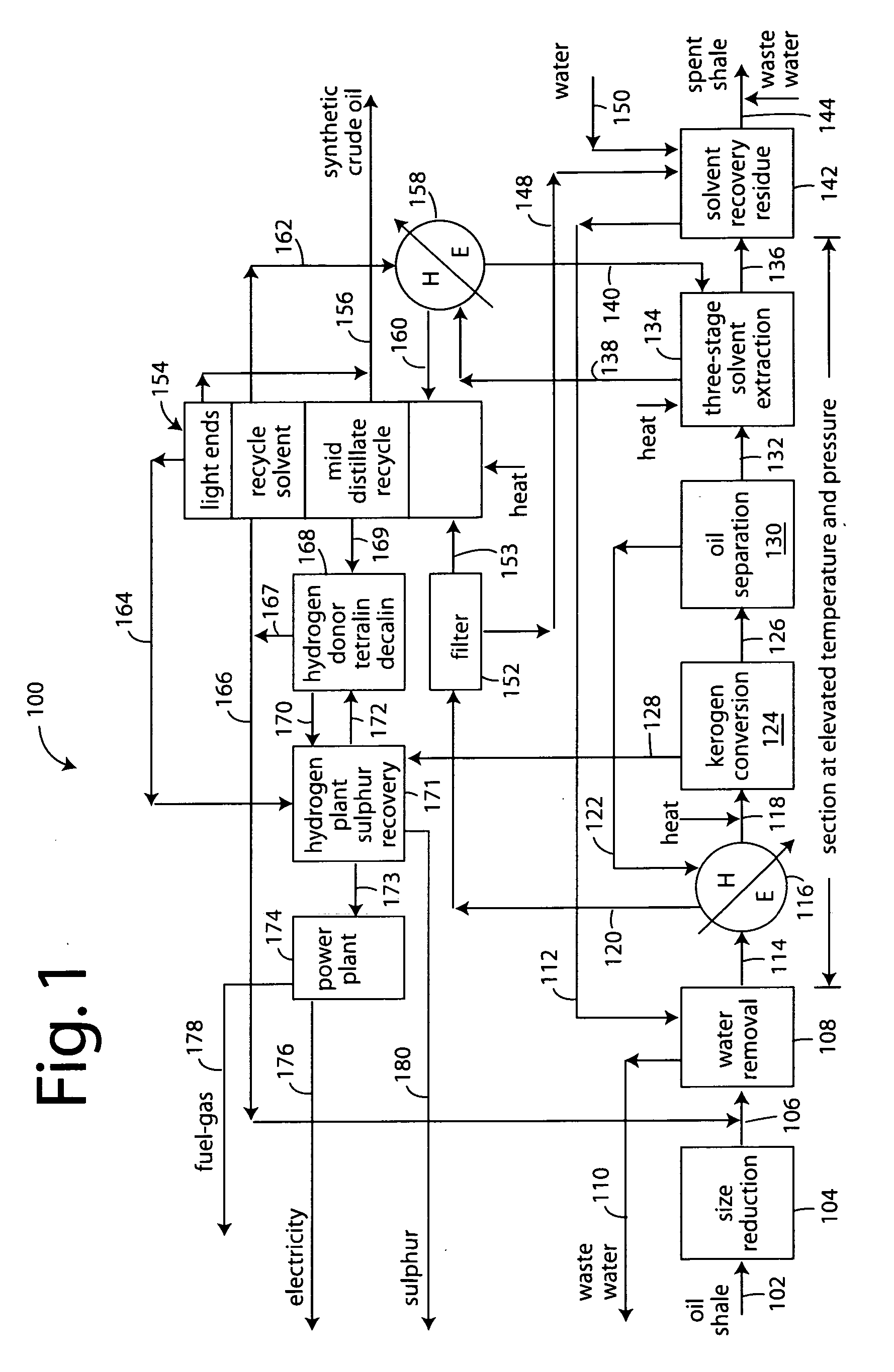

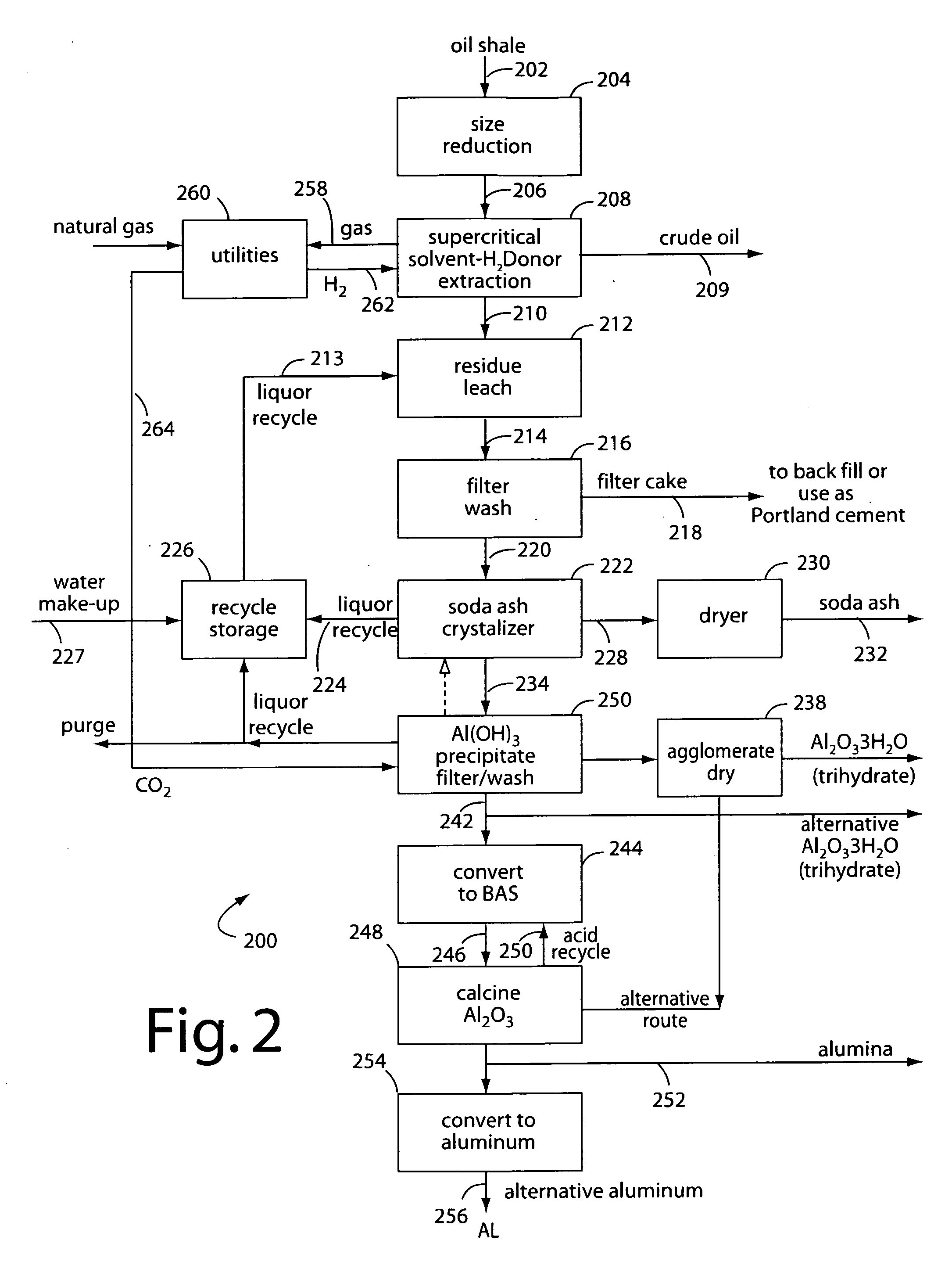

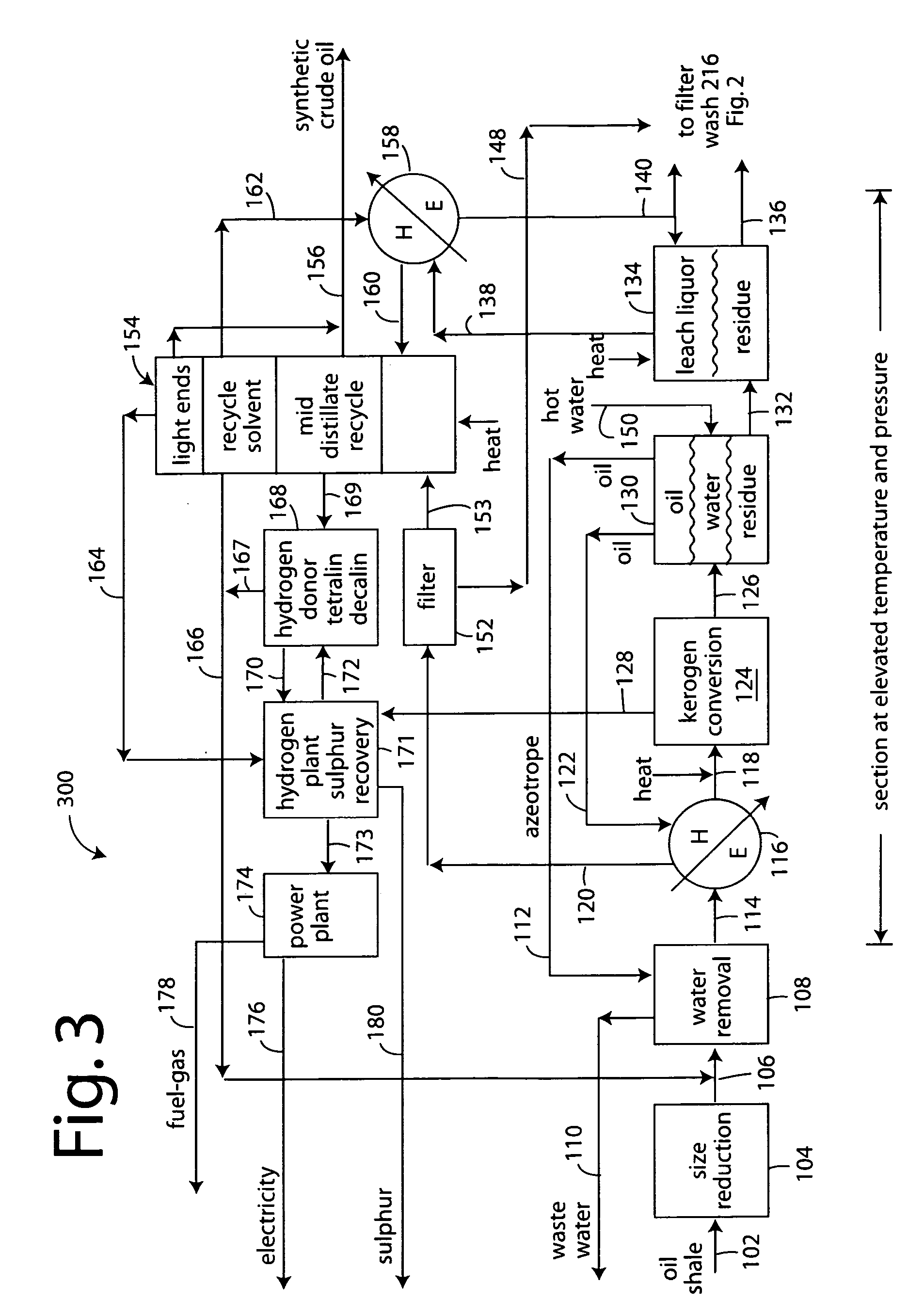

Supercritical hydroextraction of kerogen from oil shale ores

InactiveUS20070012598A1Reduce hydrogen consumptionPoint becomes highLiquid hydrocarbon mixture productionDistillationAPI gravity

Water is added to reduce the hydrogen consumption in kerogen conversion. The water is not stripped from oil shale ores, instead up to 10% w / w of water is added in the kerogen conversion at 400-475° C. The recycle solvent for conversion is changed to a high boiling point fraction of the oil, with a minimum boiling point of the order of 245° C. Such repeated recycling of high boiling fraction oil with a hydrogen-donor mid-distillate will remove additional sulphur, oxygen and nitrogen. It improves the quality of the final product oil. Most of the high boiling fraction of the oil will separate from the oil shale ores, at around 450° C. and 650 psig. Then it is reduced to 250° C. at 100 psig before distillation. Such column operates at around 10 to 250 psig, but preferably 50 psig. This improves thermal efficiency by avoiding the need to condense high boiling point vapors. The addition of water provides further enhancement in operating results. A consequence of recycling high boiling oil fractions is the repeated hydrogenation and hydrocracking of that fraction to increase the proportions of lower boiling fractions. This reduces the asphaltene content of the recycled and final product streams. Such is similar to hydro-visbreaking of bitumen, in which both the asphaltene fraction and the sulphur content can be halved, resulting in a product of 25-30° API gravity in a single pass. The recycling of high boiling fraction means approximately half of the product oil is repeatedly recycled. There is no recycle of the low boiling fractions. It is expected that the intractable asphaltene content of about 5% of the product oil will be in suspension under hydro-treating and hydro-cracking conditions. These are removed with the solids after a supercritical solvent wash.

Owner:RP INT

Process and apparatus for upgrading steam cracker tar using hydrogen donor compounds

ActiveUS8197668B2Efficiently managing introductionIncrease percentageThermal non-catalytic crackingTreatment with plural serial cracking stages onlyThermodynamicsTetralin

A process and apparatus are provided for upgrading steam cracker tars from steam crackers. The invention also relates to a steam cracking process and apparatus for reducing yields of tars produced from steam cracking while increasing yields of higher value products by heating steam cracker tar, in the presence of hydrogen donor compounds, e.g., tetralin. The hydrogen donor compounds can be provided in a hydrogen donor-rich hydrocarbon stream, e.g., light cycle oils, or low sulfur vacuum tower bottoms. The treated tar can be separated into gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

Method for producing clean fuel oil from ethylene tar

ActiveCN103102974AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesTarFuel oil

The invention discloses a method for producing clean fuel oil from ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline and coker diesel oil, performing hydrofining on the coker gasoline, mixing the coker diesel oil with the ethylene tar light fraction, subjecting the mixture to hydrotreating, and leaving the reaction effluent and the coker gasoline hydrofining product together to undergo separation by a fractionating tower, thus obtaining clean gasoline and diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes according to the composition characteristics of each fraction, thus not only enhancing the utilization rate of ethylene tar, increasing the yield of light fuel oil, but also improving the product quality of light fuel oil, and enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

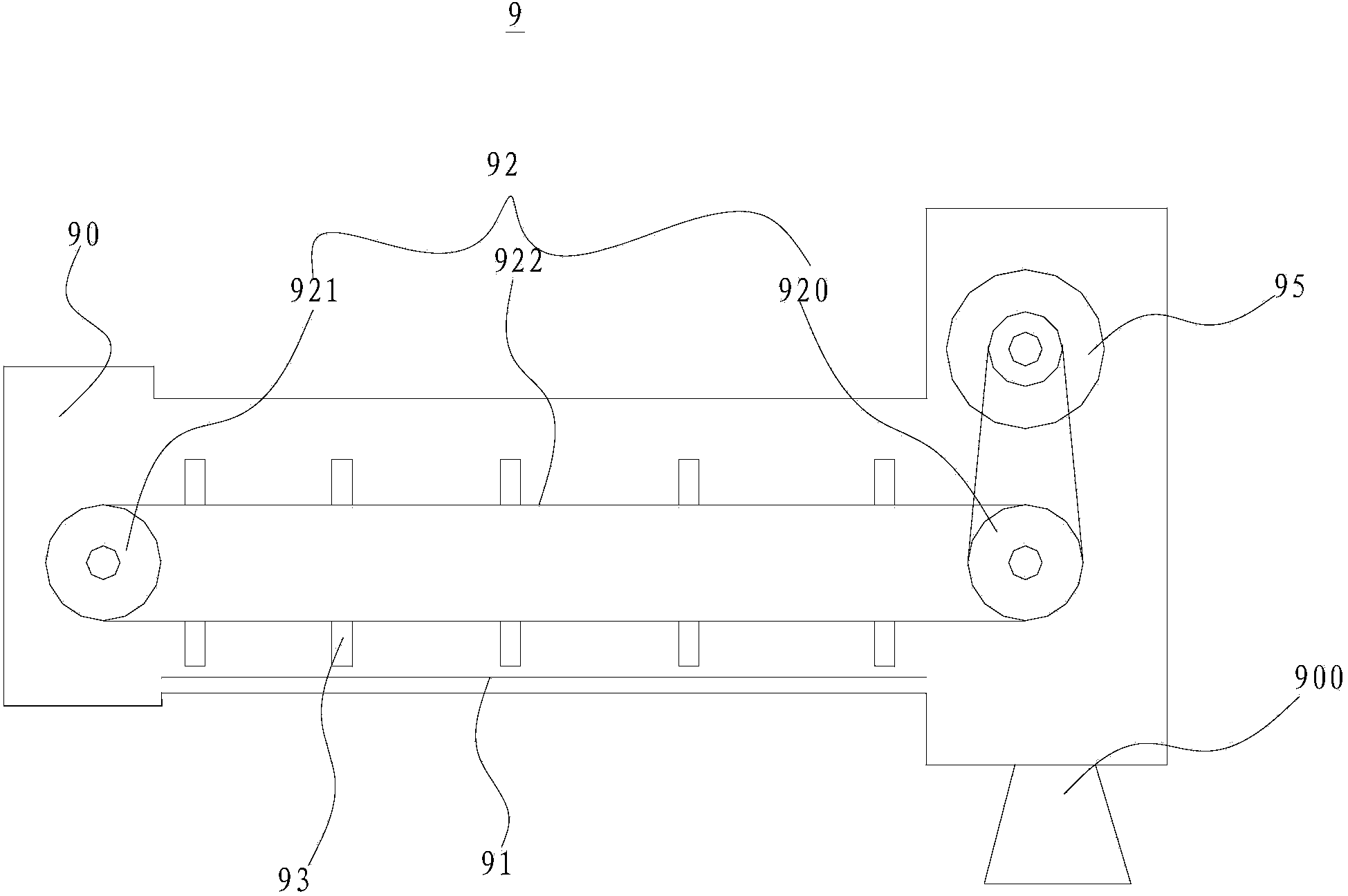

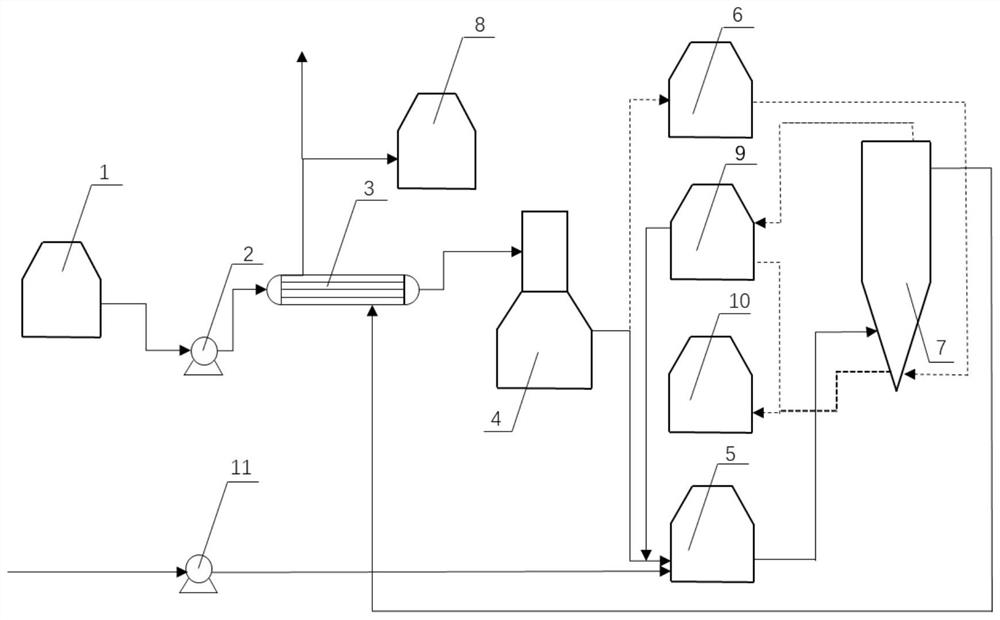

Tire treatment system

The invention discloses a tire treatment system. The tire treatment system comprises a pretreatment device, a revolving bed pyrolyzing furnace, a heat accumulating type fuel gas radiating pipe burner, a direct cooling tower, an oil cooler, an oil storage tank, a purifier, and a gas storage tank, wherein the pretreatment device treats a tire so as to form a pyrolyzing raw material. The revolving bed pyrolyzing furnace receives the pyrolyzing raw material, and a plurality of gas outlets are formed in the side wall of the revolving bed pyrolyzing furnace. The heat accumulating type fuel gas radiating pipe burner heats the pyrolyzing raw material, and a plurality of gas outlets are located below the heat accumulating type fuel gas radiating pipe burner in vertical direction. The direct cooling tower receives an oil-gas product and separates oil from gas. The oil cooler receives and cools the separated pyrolyzing oil, and the cooled pyrolyzing oil is introduced into the direct cooling tower. The oil storage tank and the oil cooler are communicated. The purifier receives the separated pyrolyzing gas. The gas storage tank and the purifier are communicated, and the gas storage tank provides a gas source for the heat accumulating type fuel gas radiating pipe burner. The tire treatment system, pyrolyzing oil is high in yield and good in quality, and the operating cost is low.

Owner:北京节净环保科技有限公司

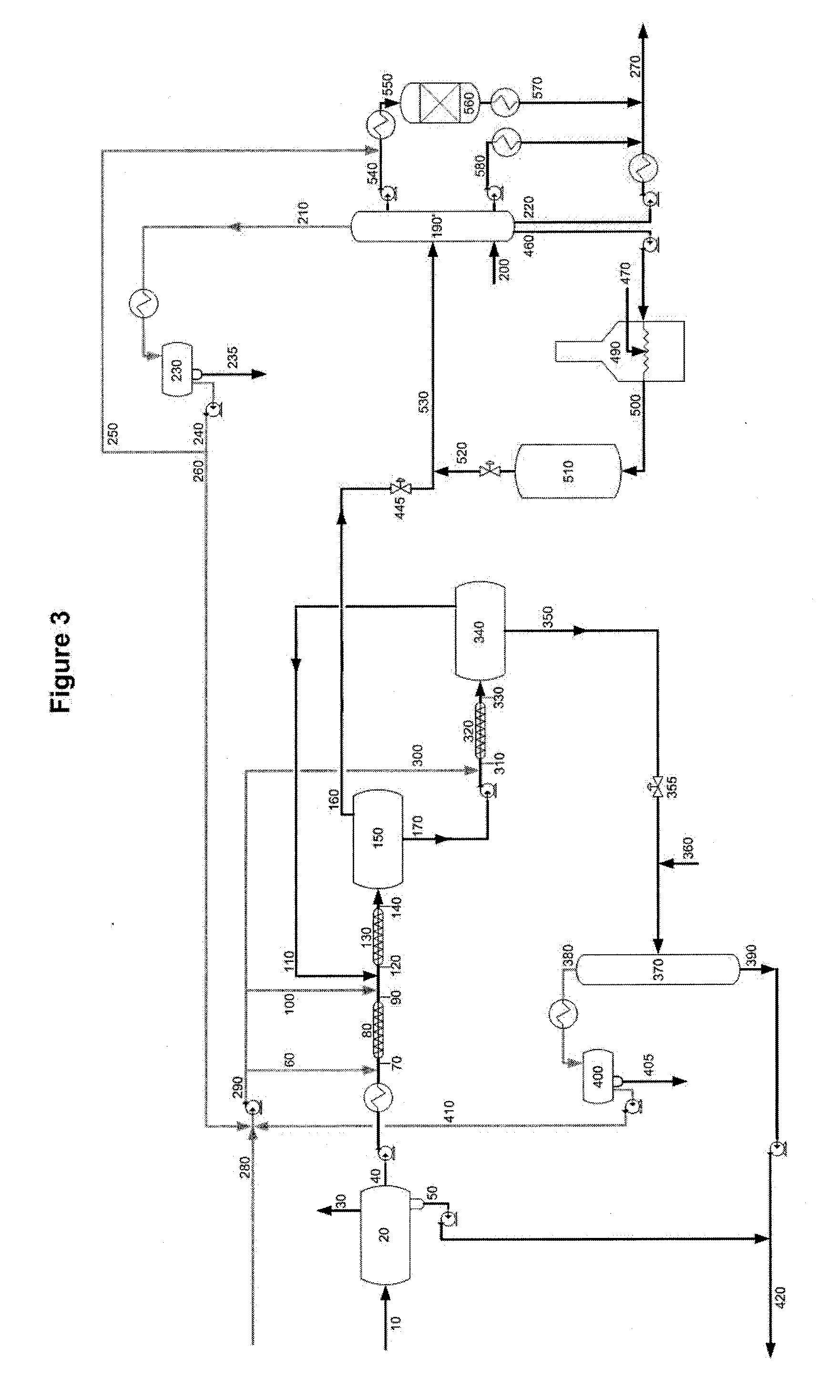

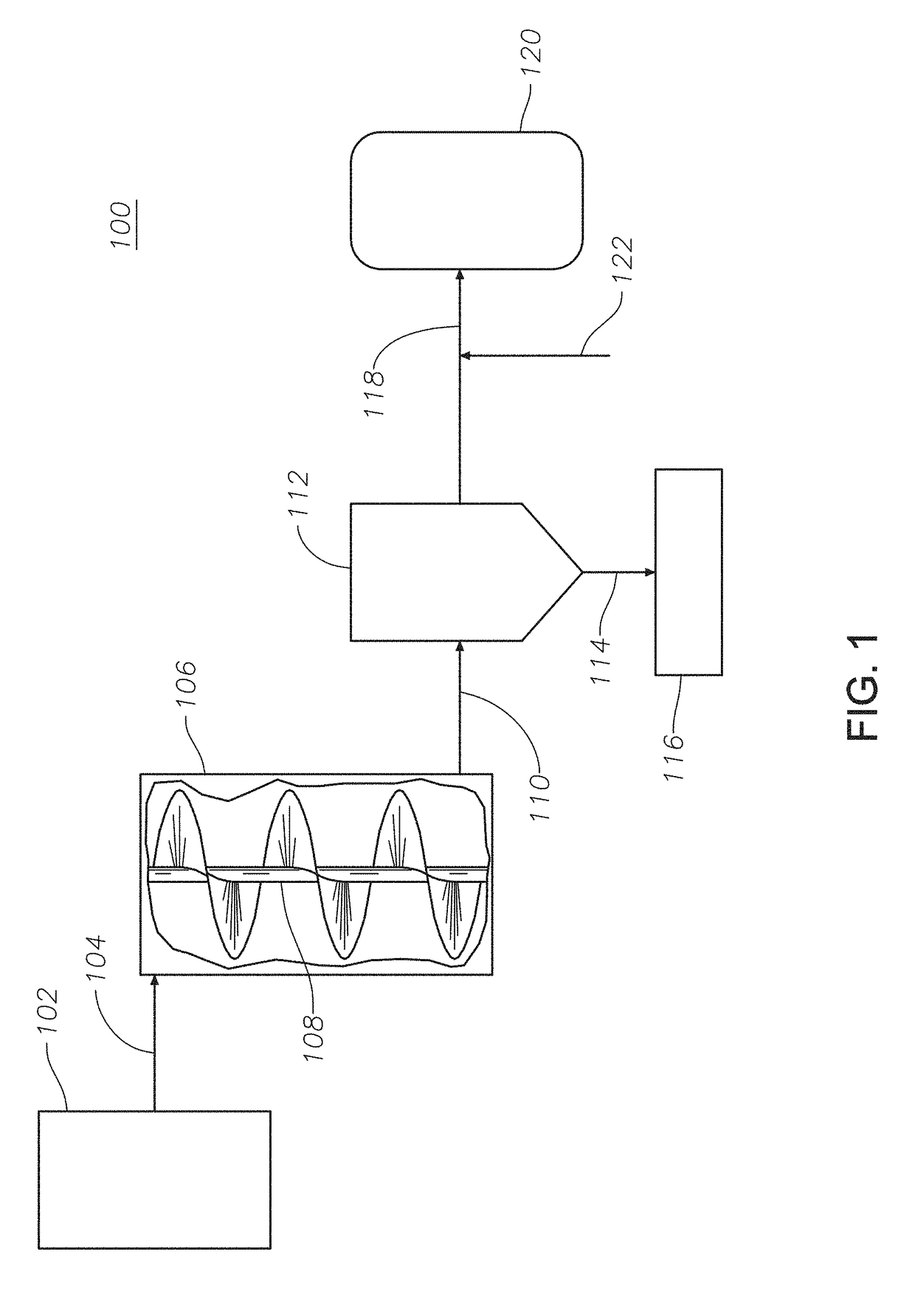

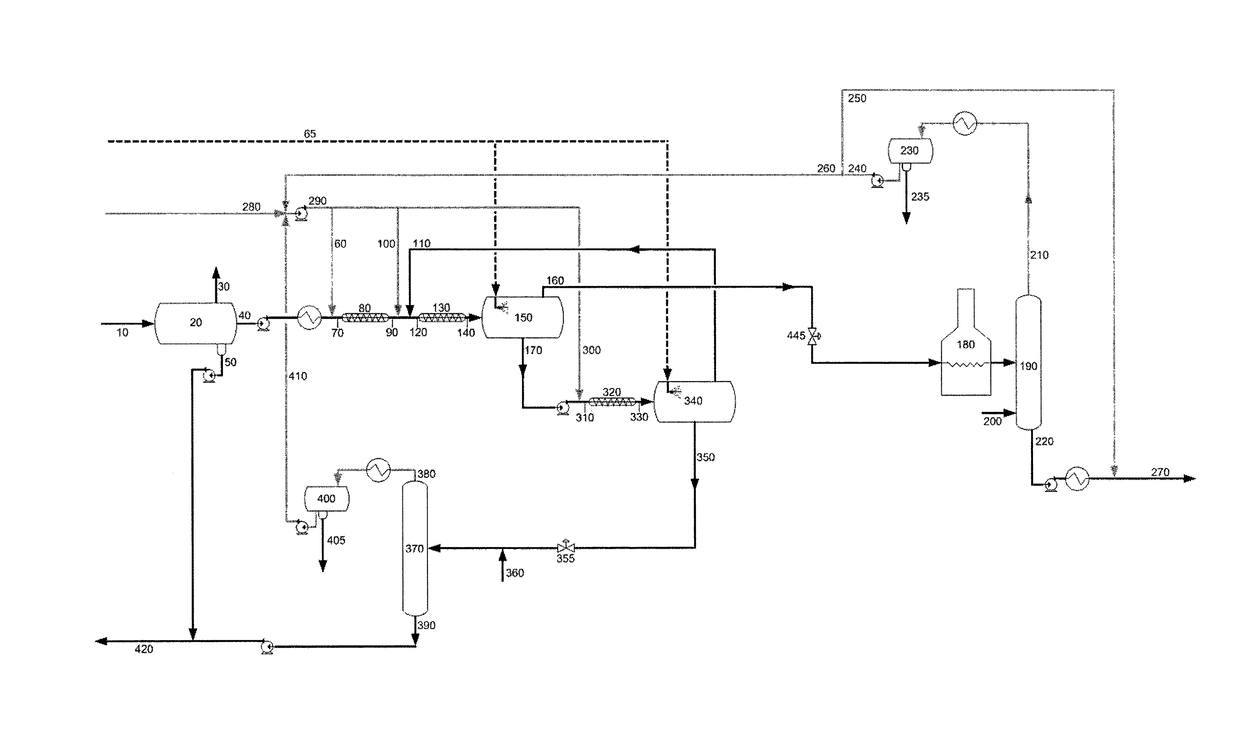

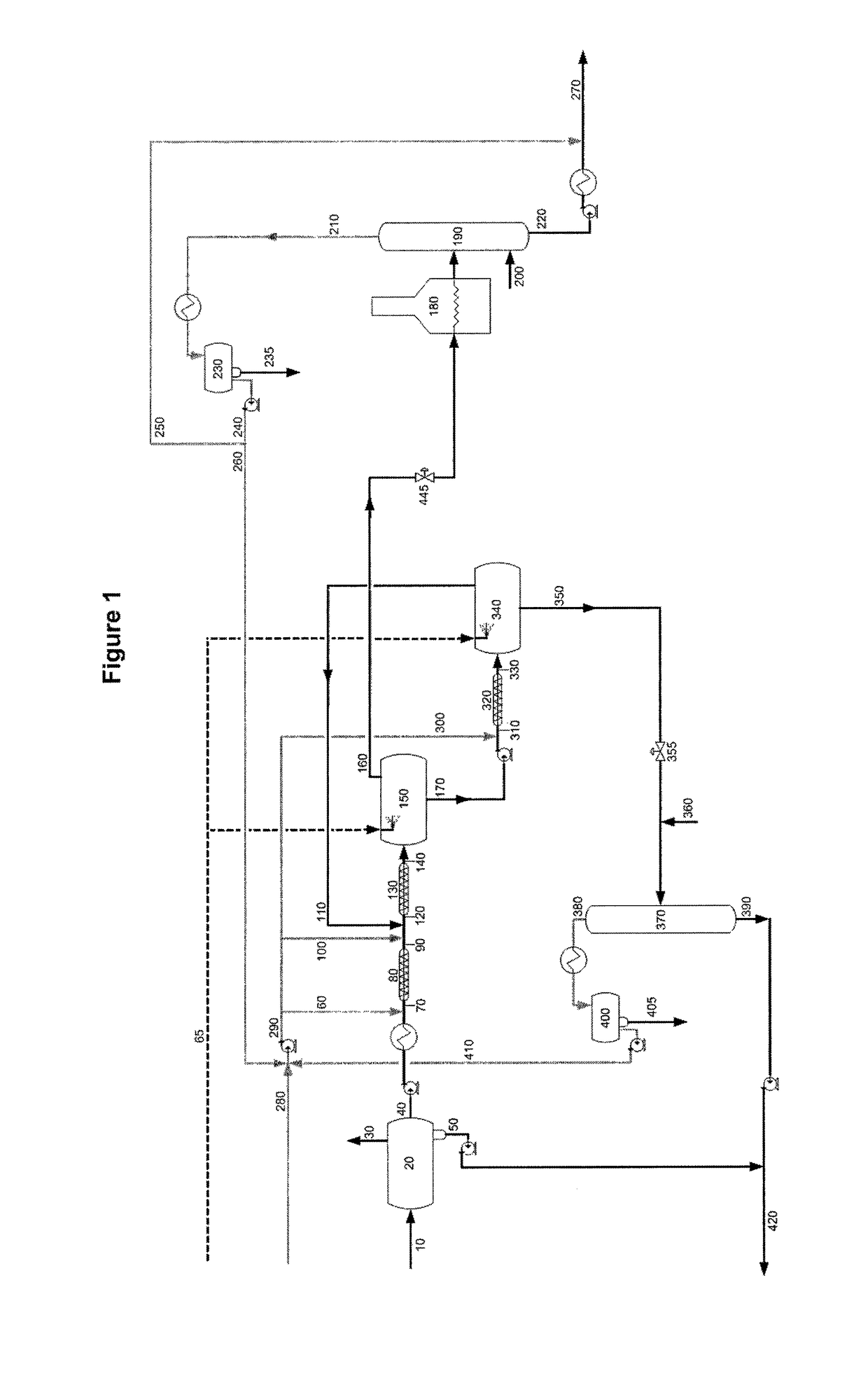

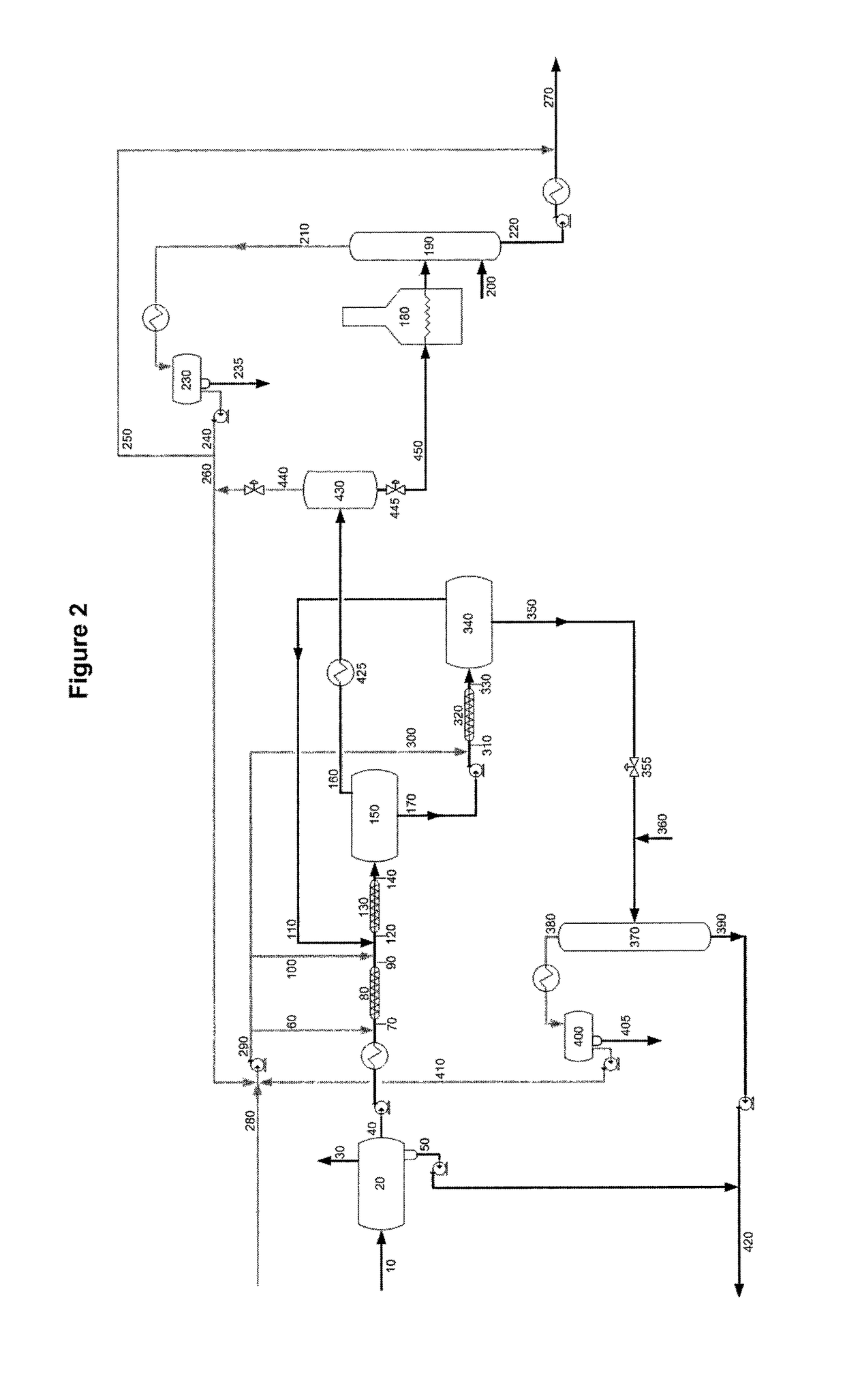

Integrated central processing facility (CPF) in oil field upgrading (OFU)

ActiveUS20140138287A1Conducive to agglomerationIncreased floc sizeThermal non-catalytic crackingTreatment with plural serial stages onlyAlkaneDiluent

A process for upgrading oil including optionally pre-treating a heavy oil including at least one dissolved gas, asphaltenes, water, and mineral solids; reducing at least one dissolved gas content from said heavy oil, optionally further reducing water content from said heavy oil; adding a paraffinic solvent to said heavy oil, at a predetermined paraffinic solvent:heavy oil ratio, facilitating separation of asphaltenes, water, and mineral solids from the heavy oil resulting in a de-asphalted or partially de-asphalted oil (“DAO”)-paraffinic solvent stream, comprising a low asphaltenes content DAO-paraffinic solvent stream and an asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the paraffinic solvent and water from the asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the DAO-paraffinic solvent stream into a paraffinic solvent rich stream and a DAO stream; and optionally adding diluent to the DAO stream resulting in transportable oil.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

Integrated process for mesophase pitch and petrochemical production

ActiveUS20190078023A1Decrease viscosity and boiling pointFew pointCatalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansPetrochemicalChemistry

An integrated method for mesophase pitch and petrochemicals production. The method including supplying crude oil to a reactor vessel; heating the crude oil in the reactor vessel to a predetermined temperature for a predetermined amount of time; reducing asphaltene content in the crude oil by allowing polymerization reactions to occur in the reactor vessel at an elevated pressure in the absence of oxygen; producing a three-phase upgraded hydrocarbon product comprising gas, liquid, and solid hydrocarbon components, where the liquid hydrocarbon component comprises deasphalted oil and the solid hydrocarbon component comprises mesophase pitch; separating the gas, liquid, and solid hydrocarbon components; directly utilizing the liquid hydrocarbon component for petrochemicals production; and directly utilizing the solid hydrocarbon component for carbon artifact production.

Owner:KING ABDULLAH UNIV OF SCI & TECH +1

Preparation method and application of catalyst for visbreaking behavior of heavy oil by aquathermolysis

InactiveCN109675561AReduce gelatinLow asphaltene contentCatalytic crackingDrilling compositionReaction temperatureSolvent

The invention belongs to the field of catalyst synthesis, and particularly relates to a preparation method and an application of a catalyst for visbreaking behavior of heavy oil by aquathermolysis. The method comprises specific steps as follows: ferric chloride is weighed and added to a three-neck beaker, ethanol, water, n-hexane and oleic acid are added to the three-neck beaker in sequence, magnetic stirring is performed, NaOH is added, heating and reflux condensation are performed, after a ferric oleate compound and an oleic acid mixture are synthesized and added to sodium alkylbenzene sulfonate, a mixture is dissolved in octyl ether, 1-octadecene or 1-eicosylene, a mixed solution is subjected to temperature programming and then cooled to the room temperature, ethanol is added to the solution, centrifugal separation is performed, and the target product, namely, the catalyst for visbreaking behavior of the heavy oil by aquathermolysis is obtained. The target product is cheap and easily available and has low energy consumption and excellent visbreaking effect, and physical properties and nanoscale can be set by selecting correct reaction temperature, reaction solvent or reaction time.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Road asphalt agglutinate and its preparation method

InactiveCN1493652AIncreased asphaltene contentLow asphaltene contentTar working-up by distillationColloidResidual oil

An asphalt cementing material for spreading pavement in tropical region is prepared from proper heavy oil through ordinary-pressure or vacuum distilling to obtain vacuum residual oil, removing asphalt by solvent to obtain the target asphat, and optionally further treating such as oxidizing or mixing it with residual oil. Its advantages are high content of asphalt colloid, low content of asphalt, and high softening point (60 deg.C) and viscosity.

Owner:CHINA PETROLEUM & CHEM CORP +1

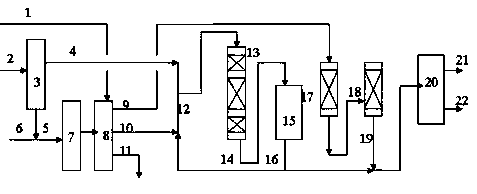

Production method of coal-based needle coke

ActiveCN102965133ALow asphaltene contentSimplified cold formingWorking-up pitch/asphalt/bitumen by selective extractionCoking carbonaceous materialsAromatic solventEngineering

A production method of coal-based needle coke aims to save energy and improve product quality. The method provided by the invention comprises the steps of: first dehydrating coal tar to moisture content of 2-3%, heating to 120-130 DEG C, and then dehydrating to moisture content of less than 0.5%; then heating to 390-410 DEG C; sending coal tar pitch at bottom of the two-stage evaporator into a bulkhead type coal tar pitch extraction column; respectively heating an aliphatic extraction solvent and an aromatic extraction solvent to 110-250 DEG C, and mixing 0.5-1 part of an aliphatic solvent and 3-5 parts of an aromatic solvent to obtain an extractant; mixing the extractant and the coal pitch in a weight ratio of 1:0.5-1.3, and adding the mixture from the upper part of the bulkhead type coal tar pitch extraction column; discharging purified coal tar pitch from the middle part of the bulkhead type coal tar pitch extraction column; adding coking heavy oil into the coal tar pitch for modulation, sending the mixture into a middle part of a delayed coking distillate tower, distilling and pumping out from tower bottom, and heating the mixture at 520-580 DEG C and sending the mixture into the coking tower to obtain green coke; and calcining in a rotary furnace for 3-12 h, and escaping remaining volatile matters to prepare the coal-based needle coke.

Owner:山西永东化工股份有限公司

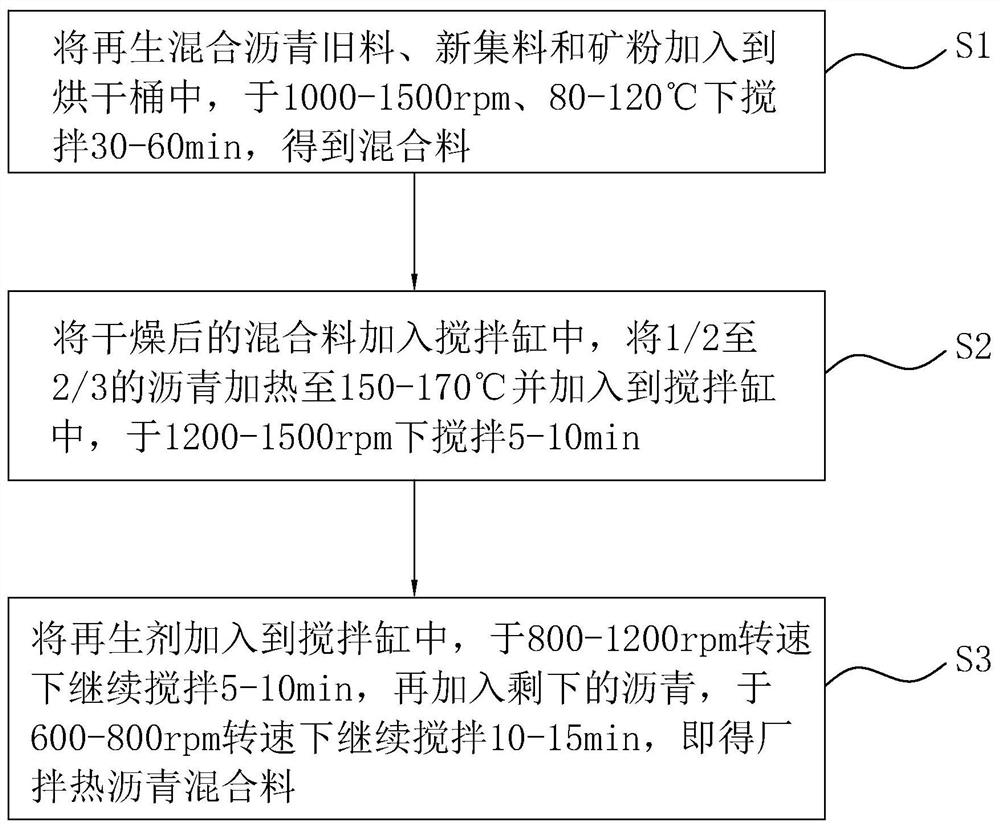

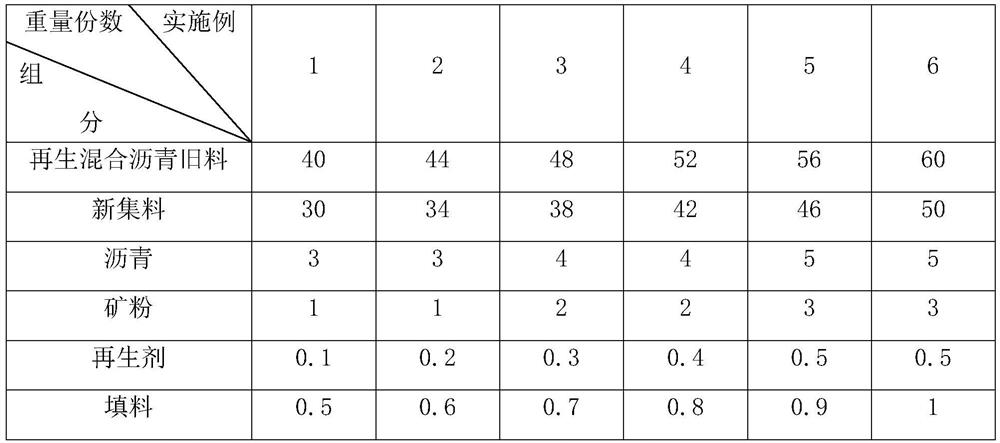

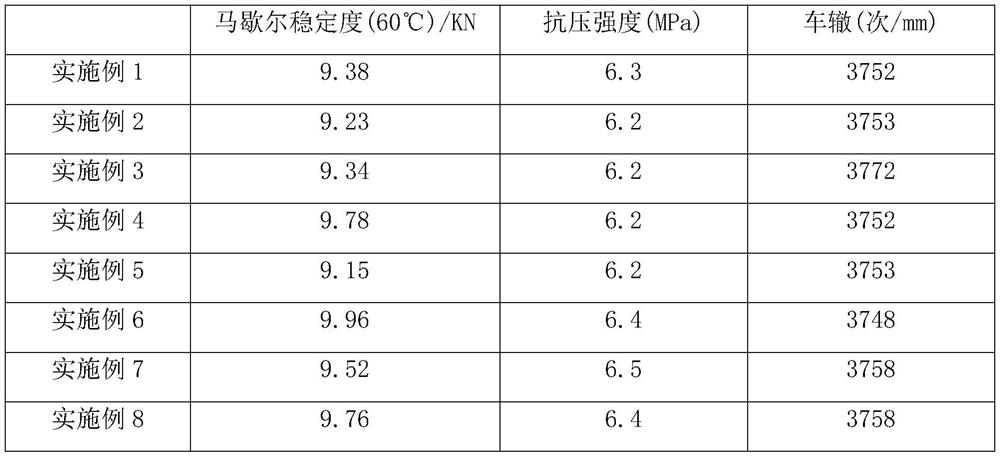

Plant-mixed hot asphalt mixture and preparation method thereof

InactiveCN111747683AImprove structural strengthExtended service lifeSolid waste managementProcess engineeringAsphalt

The invention discloses a plant-mixed hot asphalt mixture and a preparation method thereof, and relates to the technical field of recycled asphalt processing. The plant-mixed hot asphalt mixture is prepared from the following components in parts by weight: 40 to 60 parts of recycled mixed asphalt old material; 30 to 50 parts of a new aggregate; 3-5 parts of asphalt; 1-3 parts of mineral powder; 0.1 to 0.5 part of a regenerant; 0.5-1 part of filler. The preparation method comprises the following steps: S1, adding the recycled mixed asphalt old material, the new aggregate and the mineral powderinto a drying barrel, and uniformly stirring to obtain a mixture; S2, adding the dried mixture into a stirring cylinder, heating 1 / 2-2 / 3 of asphalt to 150-170 DEG C, adding the asphalt into the stirring cylinder, and uniformly stirring; and S3, adding the regenerant into the stirring cylinder, uniformly stirring, adding the remaining asphalt, and uniformly stirring to obtain the plant-mixed hot asphalt mixture. The asphalt mixture prepared by the preparation method has the advantages of higher structural strength, longer service life and good pavement performance.

Owner:上海佳砼新材料科技发展有限公司

Integrated central processing facility (CPF) in oil field upgrading (OFU)

ActiveUS9650578B2Increase settlement rateDecreases size and costThermal non-catalytic crackingTreatment with plural serial stages onlyAlkaneDiluent

A process for upgrading oil including optionally pre-treating a heavy oil including at least one dissolved gas, asphaltenes, water, and mineral solids; reducing at least one dissolved gas content from said heavy oil, optionally further reducing water content from said heavy oil; adding a paraffinic solvent to said heavy oil, at a predetermined paraffinic solvent:heavy oil ratio, facilitating separation of asphaltenes, water, and mineral solids from the heavy oil resulting in a de-asphalted or partially de-asphalted oil (“DAO”)-paraffinic solvent stream, comprising a low asphaltenes content DAO-paraffinic solvent stream and an asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the paraffinic solvent and water from the asphaltenes-mineral solids-paraffinic solvent-water slurry stream; optionally separating the DAO-paraffinic solvent stream into a paraffinic solvent rich stream and a DAO stream; and optionally adding diluent to the DAO stream resulting in transportable oil.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

Purification method for coal tar maltha

ActiveCN102965135AEnergy savingImprove gradeWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionChemistryCoal Tar Pitches

A purification method for coal tar maltha aims to save energy and improve grade of coal asphalt raw material. The method provided by the invention comprises the steps of: conducting rough machining on the coal tar, cutting coal tar pitch with a softening point of 30-40 DEG C, and sending into a bulkhead type coal tar pitch extraction column for extraction; respectively heating an aliphatic extraction solvent and an aromatic extraction solvent to 110-250 DEG C; taking 0.5-1 part of an aliphatic solvent and 3-5 parts of an aromatic solvent, and mixing the two into an extractant by a static mixer; thoroughly stirring and mixing the extractant and coal tar pitch by a proportion of 1:0.5-1.3 with the static mixer, and adding the mixture from the upper part of the bulkhead type coal tar pitch extraction column; discharging the sulfur nitrogen compound in coal tar pitch and combined with the extractant from bottom of the extraction column, so as to purify coal tar pitch by removal of sulfur compounds; and discharging the coal tar pitch from the middle part of the bulkhead type coal tar pitch extraction column.

Owner:山西永东化工股份有限公司

Method for increasing yield of clean fuel oil

ActiveCN103773497AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesProcess engineeringFuel oil

The invention discloses a method for increasing the yield of clean fuel oil. The method comprises the following steps: subjecting ethylene tar to fractionation so as to obtain a light fraction and a heavy fraction, mixing the heavy fraction with a conventional coking raw material, then subjecting the mixture to a delay coking treatment so as to obtain a coking product, transporting the coking product and a C9 component from an ethylene device into a coking distillation tower, carrying out a distillation treatment so as to obtain a coking gasoline fraction and a coking diesel oil fraction, carrying out a hydro-refining treatment on the obtained coking gasoline fraction, mixing the coking diesel oil fraction with the ethylene tar light fraction, then subjecting the mixture to a hydro-treatment, and separating the products so as to obtain a gasoline product and a diesel oil product. The method fully utilizes the ethylene tar and C9 fraction, improves the utilization rate of by-products of ethylene device, prominently improves the yield and quality of lightweight fuel oil, and is beneficial for yield increasing of high quality clean fuel oil for refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light fuel oil from ethylene tar

ActiveCN103102979AImprove product qualityBroaden sources of raw materialsTreatment with hydrotreatment processesLighter fuelGasoline

The invention discloses a method for producing light fuel oil from ethylene tar. The method is as below: fractionating ethylene tar into a light fraction and a heavy fraction; mixing the heavy fraction with a conventional coking raw material, and subjecting the mixture to delayed coking to obtain coker gasoline, coker diesel and coker gas oil; mixing the coker gasoline and the coker diesel with the light fraction of the ethylene tar, and subjecting the mixture to a hydrofining reaction; distilling the product to obtain a gasoline fraction I and a fraction heavier than the gasoline; subjecting the fraction heavier than the gasoline to a hydrogenation treatment to obtain light fuel oil, and distilling to obtain a gasoline fraction II and a diesel product; and mixing the gasoline fraction I and the gasoline fraction II to obtain a final gasoline product. The method provided by the invention utilizes the characteristics of high contents of ethylene tar aromatic hydrocarbons, colloid, carbon residue and glial and asphaltene of ethylene tar to fractionate the ethylene tar into the light fraction and the heavy fraction; different processing methods are employed to improve the added value of ethylene tar, increase yield of gasoline and diesel, improve product quality of light fuel oil and realize long-period stable operation of devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

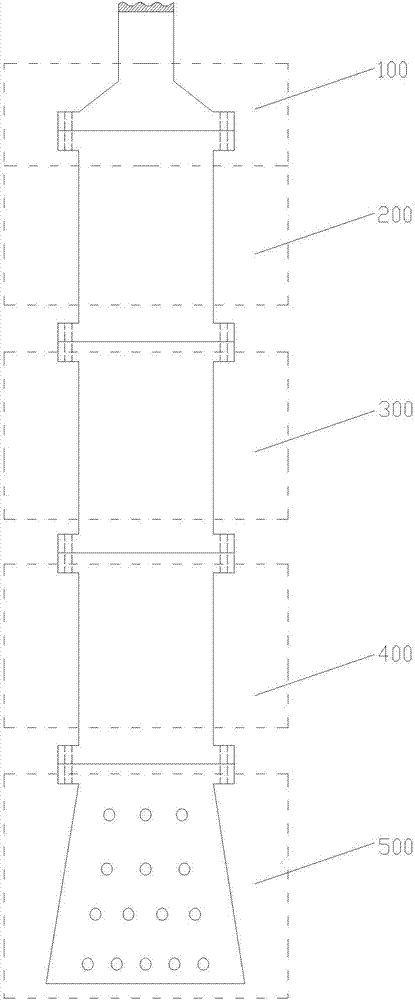

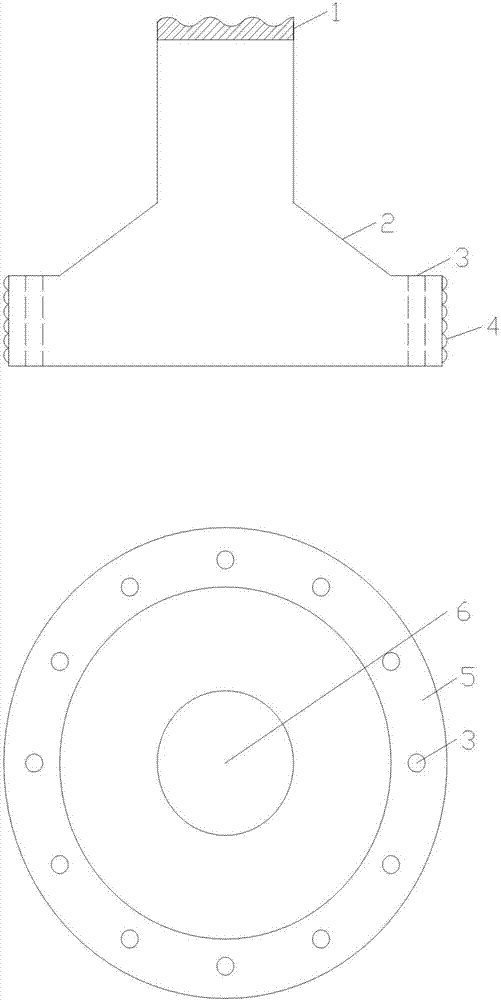

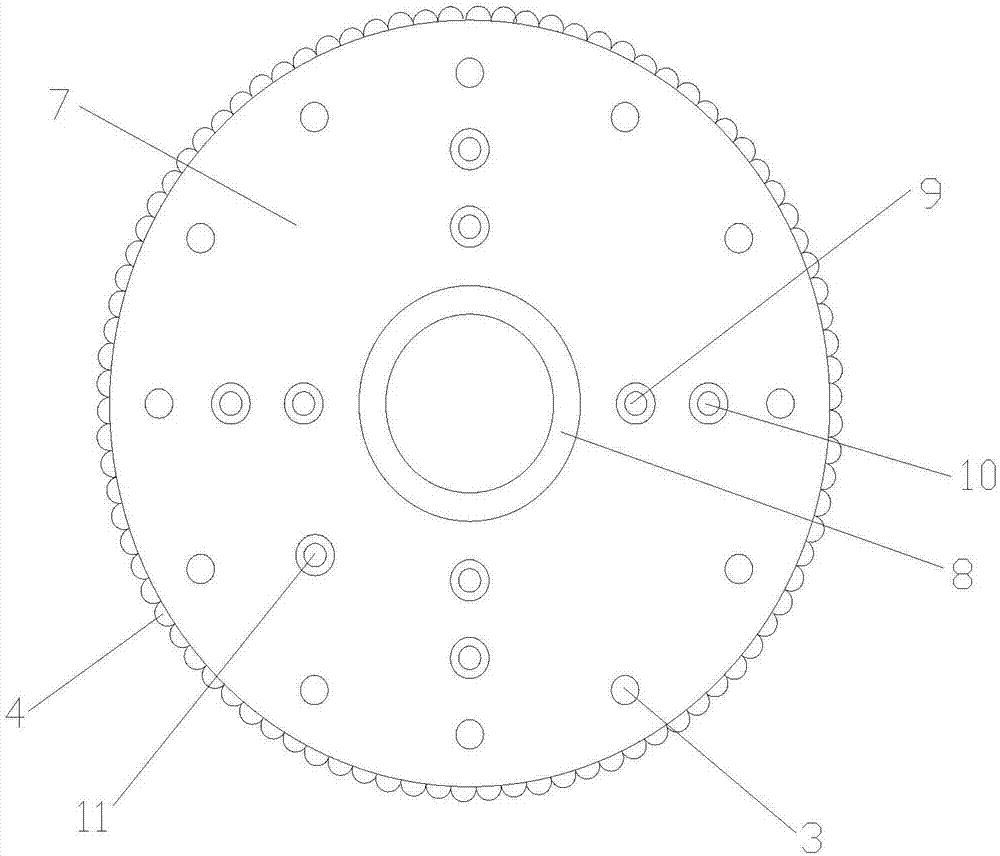

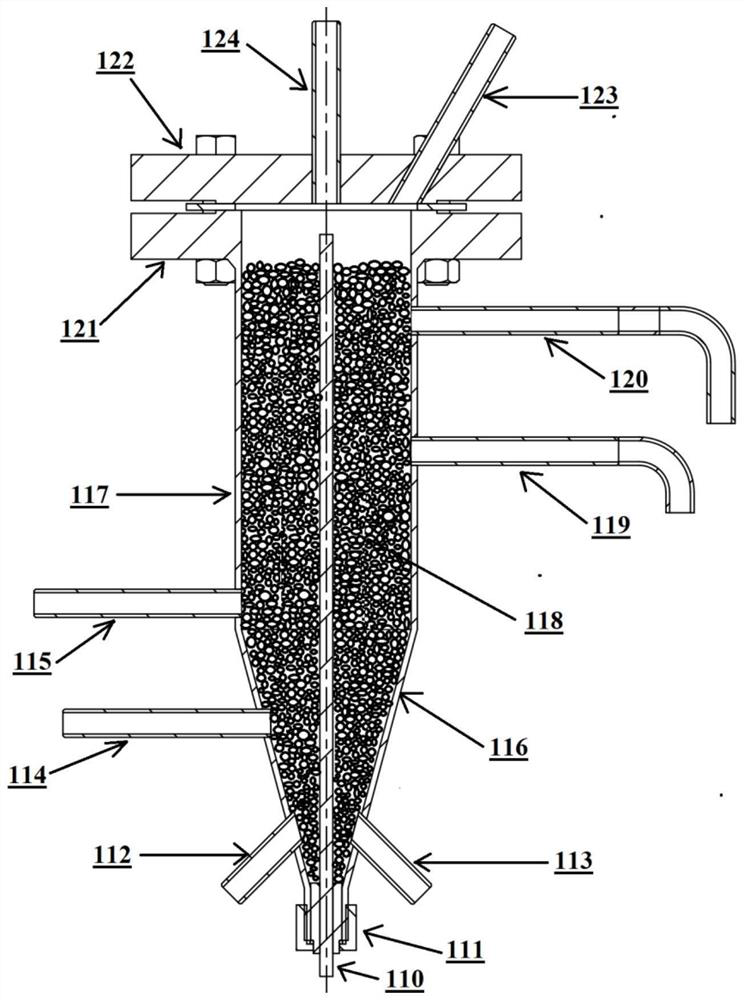

Underground mixed-phase thermal fluid generator and using method thereof

InactiveCN106996285ALow viscosityReduce weightSteam generation using pressureFluid removalEngineeringThermal fluids

The invention discloses an underground mixed-phase thermal fluid generator and a using method thereof, and relates to the field of the oil and gas extraction. The underground mixed-phase thermal fluid generator comprises a top connecting component, a burning component, a vaporizing component, a spiral pressurizing component and a spraying component. The using method comprises the following steps: supplying one or more types of fluid to the generator, forming a combustion product through the combustion of an internal fuel and an oxidizing agent, spraying water into the combustion product to form the mixed-phase thermal fluid, injecting the mixed-phase thermal fluid into oil deposit through the spiral pressurizing component and the spraying component so as to improve the extraction rate of the crude oil and the natural gas. The underground mixed-phase thermal fluid generator has the characteristics of simple application and strong adaptability, and can be applied for primary oil recovery or tertiary oil recovery of the thickened oil and super thickened oil deposit hardly extracted by the traditional oil extraction method.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

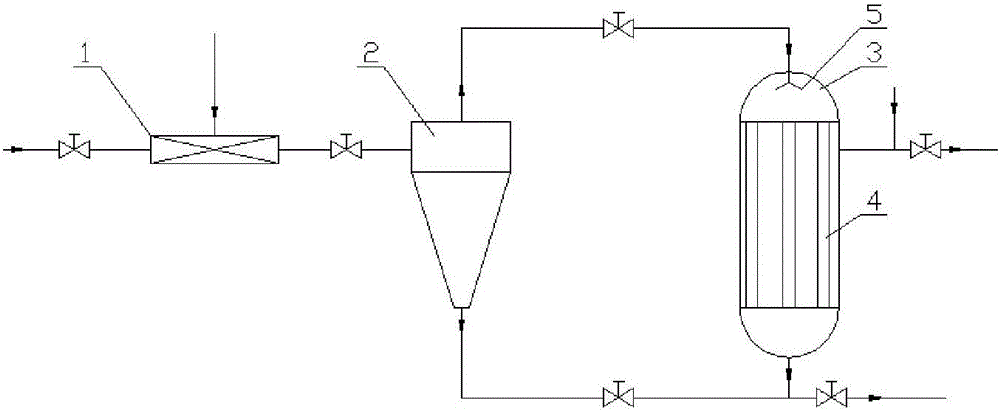

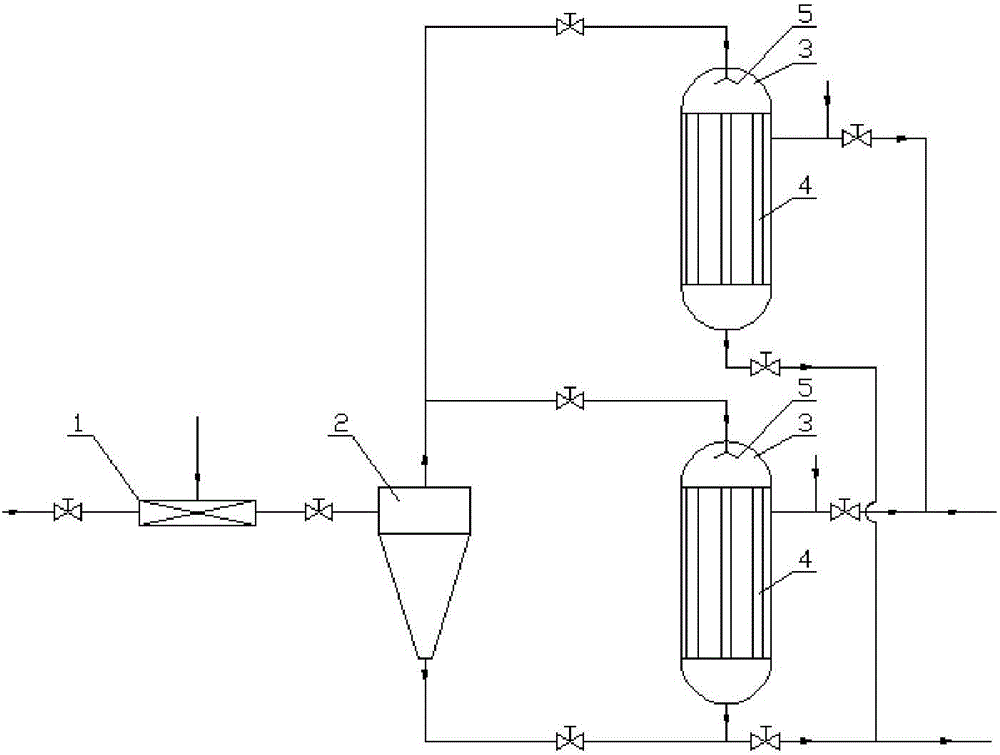

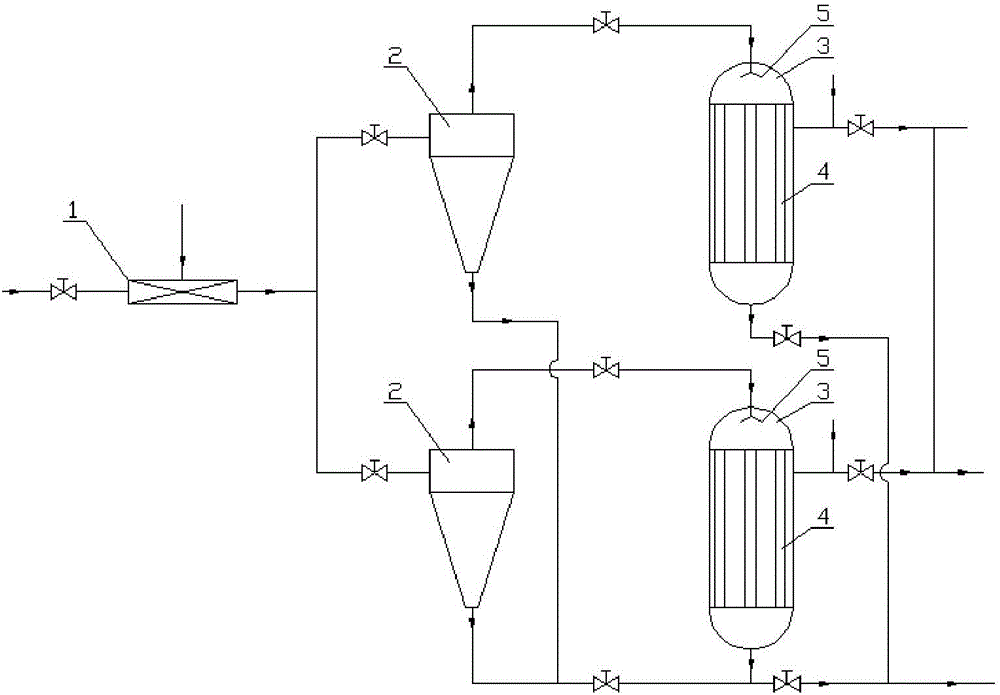

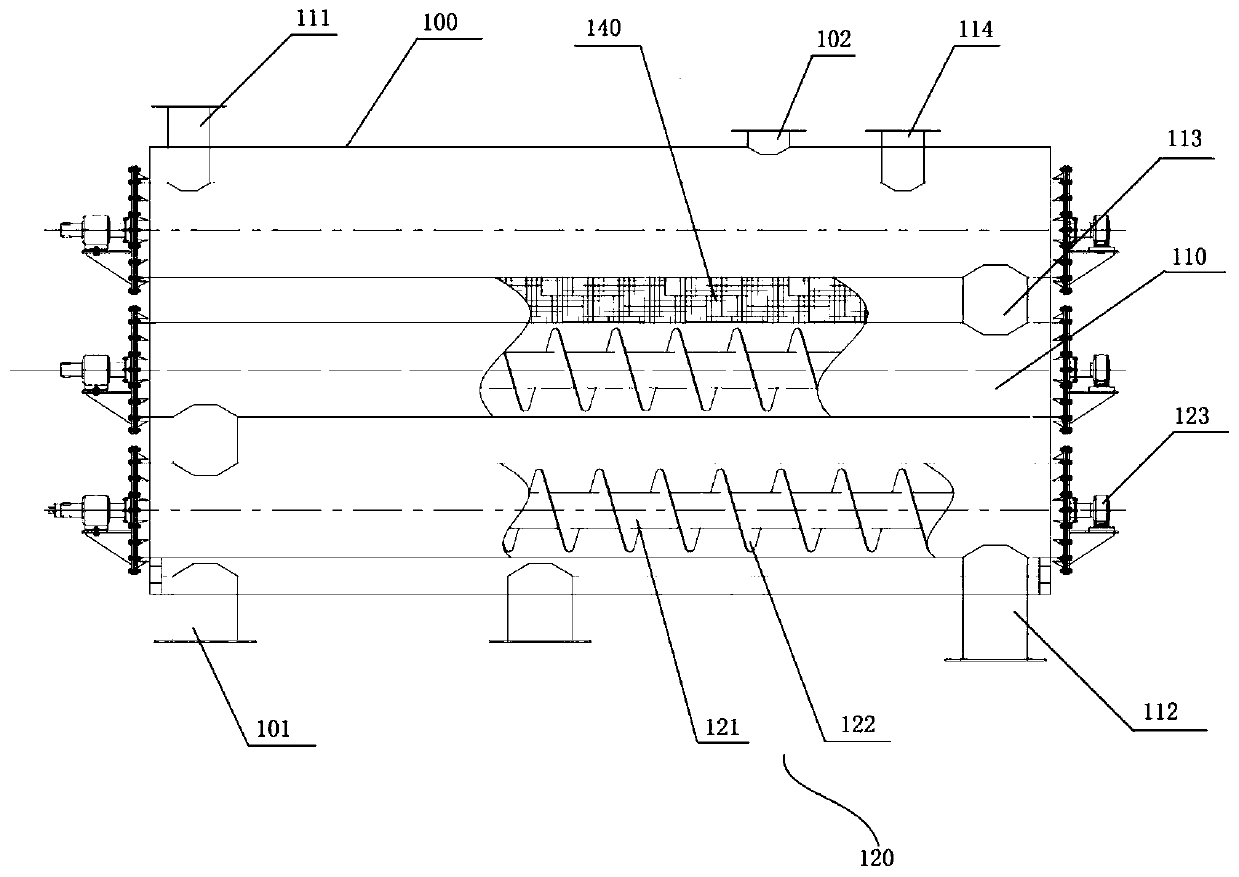

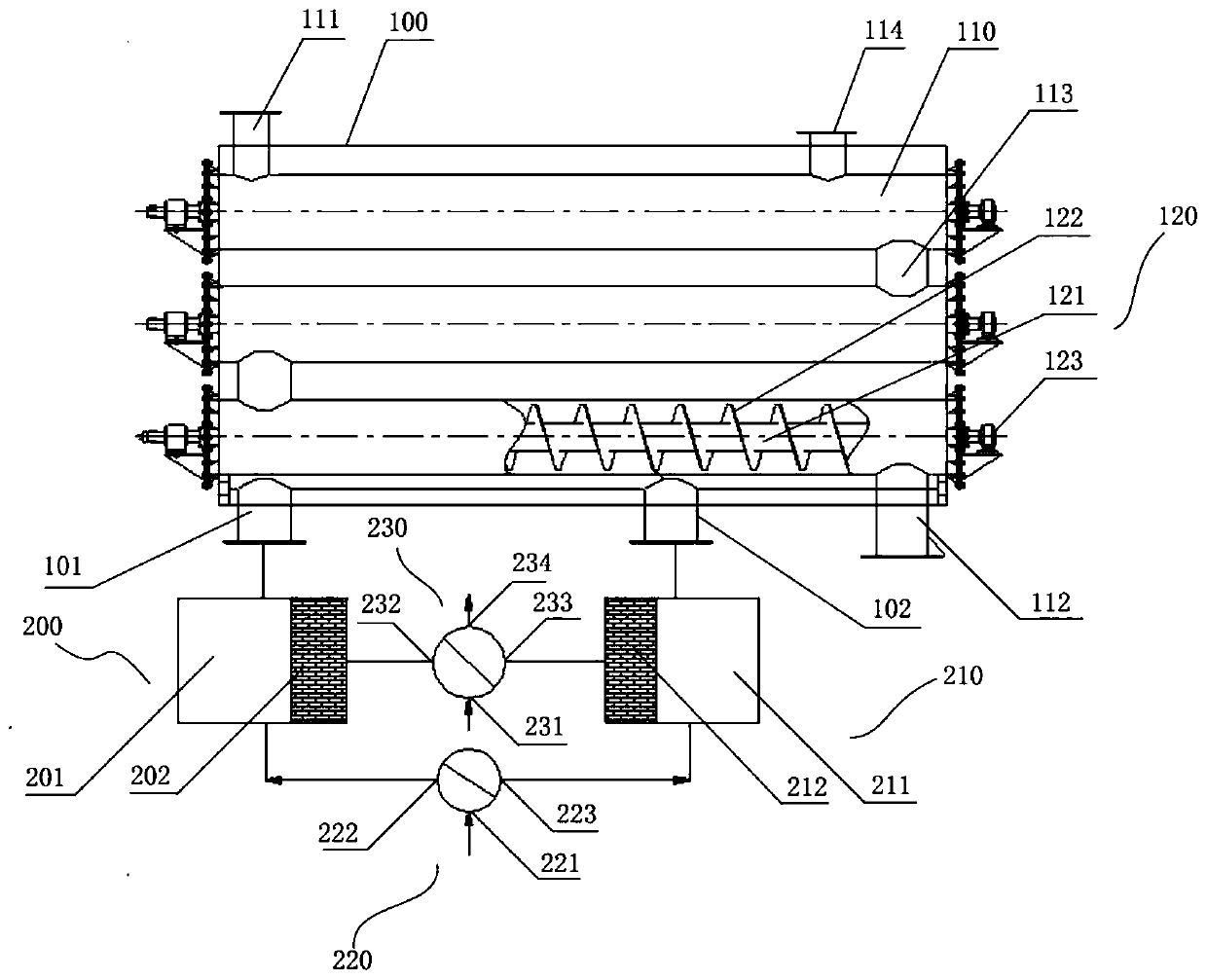

Solid-liquid separation device for oil slurry and solid-liquid separation system for oil slurry

InactiveCN106675626ASimple structureEasy to operateTreatment with plural serial refining stagesFiltration circuitsSlurrySeparation system

The invention provides a solid-liquid separation device for oil slurry and a solid-liquid separation system for oil slurry. The solid-liquid separation device for oil slurry comprises at least one mixer, at least one first-level separator and at least one second-level filter; the first-level separator is communicated with each mixer; the second-level filter is communicated with each first-level separator. Different from a traditional single filtering and separating technology, the invention adopts the first-level separation and the second-level filtering, so that the solid-liquid separation device for oil slurry can meet the requirement of long-period stable work.

Owner:SINOPEC ENG GRP CO LTD

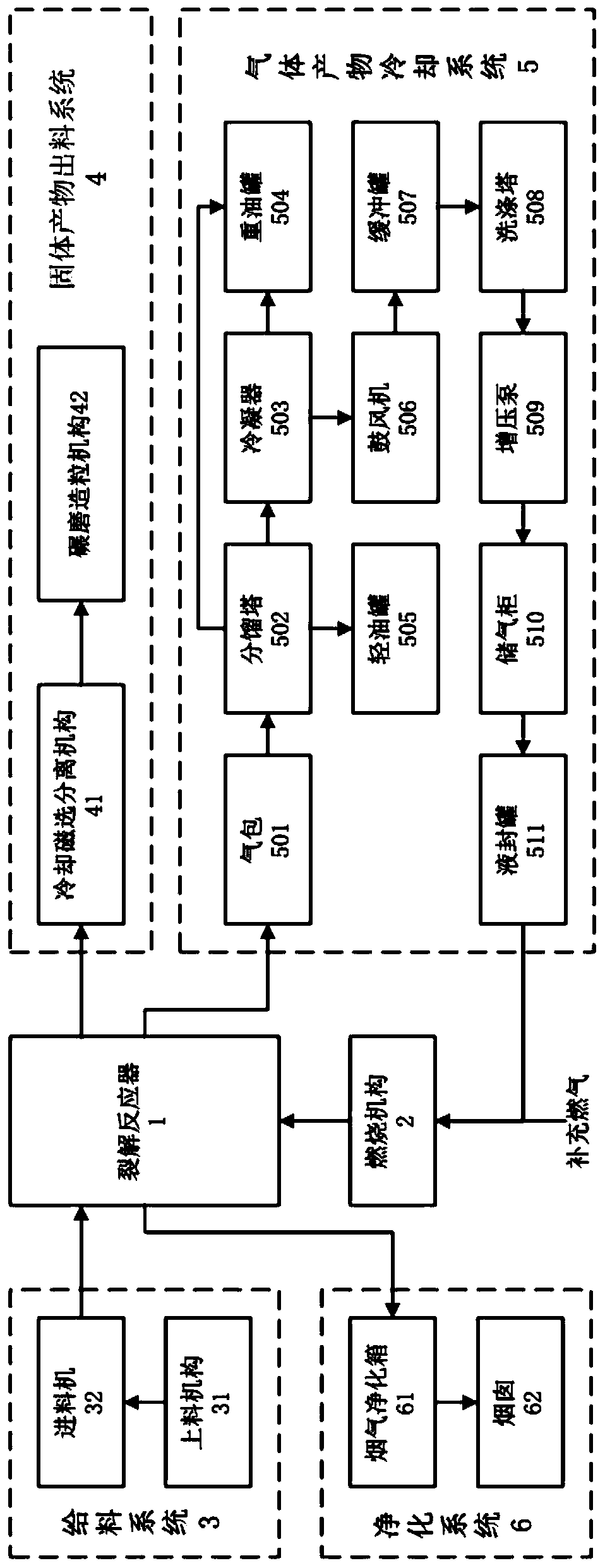

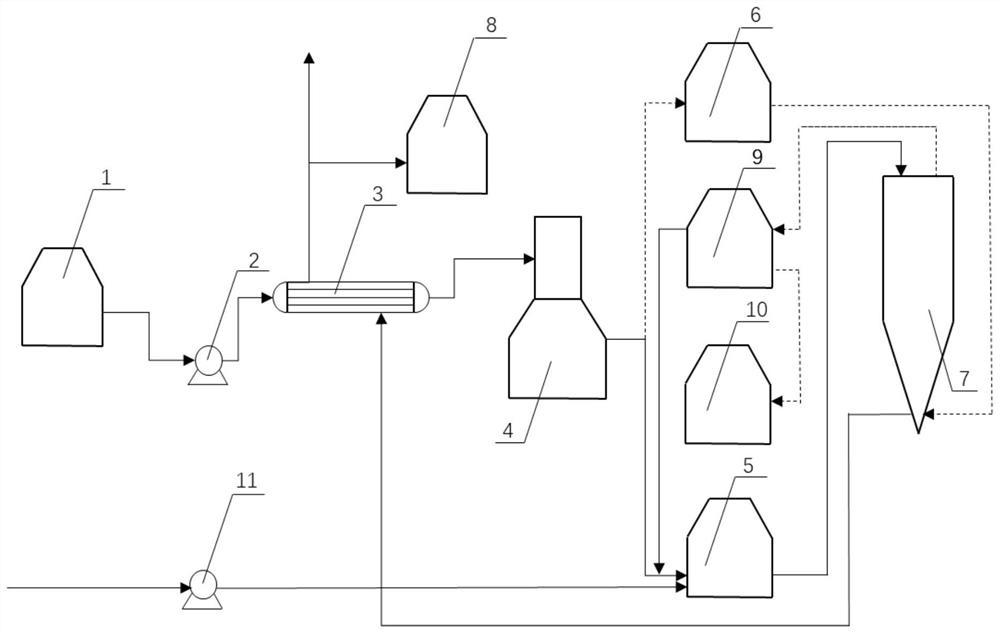

Novel rubber block pyrolysis oil production system

PendingCN110129085AStable combustionGuarantee self-sufficiencyLiquid hydrocarbon mixture productionEnvironmental resistanceCombustion

The invention discloses a novel rubber block pyrolysis oil production system, and relates to the technical field of environment-friendly equipment. The novel rubber block pyrolysis oil production system comprises a cracking reactor, a combustion mechanism, a material feeding system, a solid product discharging system, a gas product cooling system and a purification system, wherein the material feeding system is used for sending crushed rubber blocks into the cracking reactor, the cracking reactor is used for heating and cracking the rubber blocks, and the solid product discharging system is used for collecting and filtering carbon black generated in the cracking reactor, grinding the filtered carbon black, and performing granulation, drying and packaging; the gas product cooling system isused for collecting oil-gas products produced in the cracking reactor, and separating the oil-gas products so as to obtain an oil product and flammable non-condensable gas, the combustion mechanism isused for introducing and burning the flammable non-condensable gas, and sending the generated high-temperature flue gas into the cracking reactor so as to provide heat for cracking of the rubber blocks, and the purification system is used for purifying exhausted flue gas.

Owner:武汉兴泰荣达科技有限公司

Method and device for pretreating hydrogenation raw material by utilizing electric separation technology

ActiveCN112175663ASolve the pollution problemExpand sourceTreatment with hydrotreatment processesRefining by electric/magnetic meansElectrostatic separationSeparation technology

The invention provides a method for pretreating a hydrogenation raw material by using an electric separation technology, and the method solves the pollution problem of metal particles and mechanical impurities in the hydrogenation raw material through an efficient electric separation method. According to the method, the process bottleneck of a traditional electrostatic separation method is brokenthrough, the method can be operated under a high-temperature condition, colloid and asphaltene in the hydrogenation raw materials are selectively removed, and long-period, stable, continuous and efficient production operation is achieved. According to the refined oil product obtained by the invention, the metal particle removal rate is higher than 95%, the mechanical impurity removal rate is higher than 99%, the colloid and asphaltene content is low, and meanwhile, the full utilization of the backwash oil and the optimal use of peripheral system supporting facilities are realized; and the defects of redundant cleaning operation, easy blockage of a filter screen, low treatment efficiency, frequent switching, high device maintenance cost and the like of the traditional filter are overcome.

Owner:武汉兰兆科技有限公司

Method for removing metal from coal tar at low pressure

ActiveCN103725324ARaw materials are simpleHigh metal capacityTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a method for removing metal from coal tar at low pressure, which mainly solves the problem that the content of metal in all fraction of coal tar is generally higher than 200mu g / g, which highly restricts the operational cycle of a main hydrogenation unit. The method comprises steps of firstly mixing coal tar with hydrogen; then allowing the mixture to enter a fixed bed hydrogenation reactor from the top for hydrorefining reaction, wherein the fixed bed hydrogenation reactor is at least filled with a hydrogenation protective catalyst, which comprises a first protective catalyst, a second protective catalyst and a third protective catalyst which are sequentially filled from top to bottom, the reaction pressure for hydrorefining reaction is 2.8-8.5MPa; then carrying out gas-liquid separation on effluent of the fixed bed hydrogenation reactor so as to obtain the refined coal tar containing less than 2mu g / g of total metal. According to the method, the reaction is carried out at lower operation pressure, and the refined coal tar containing less than 2mu g / g of total metal is produced through hydrogenation at low pressure.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

Combined process for processing heavy oil

ActiveCN100366709CEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

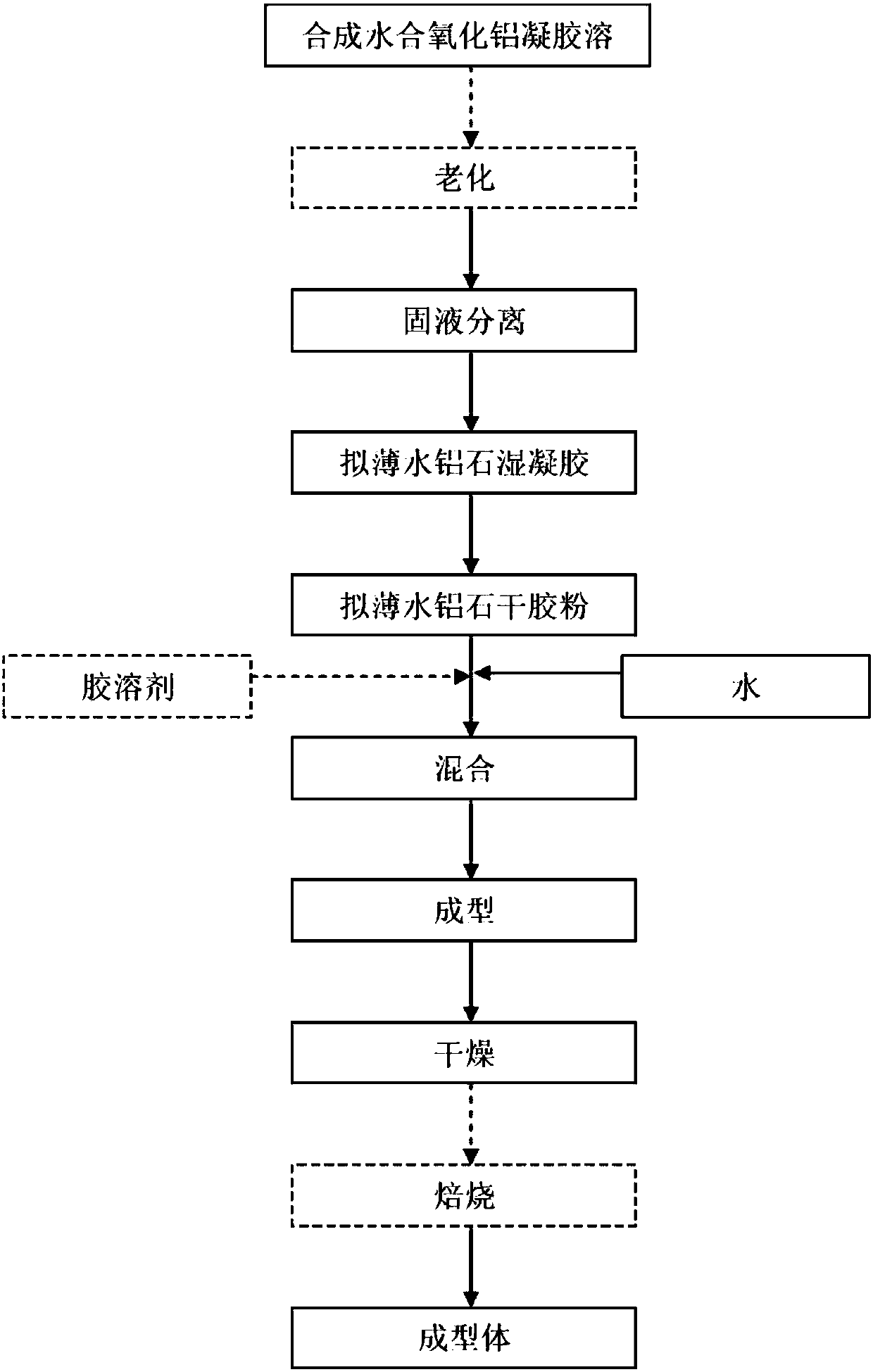

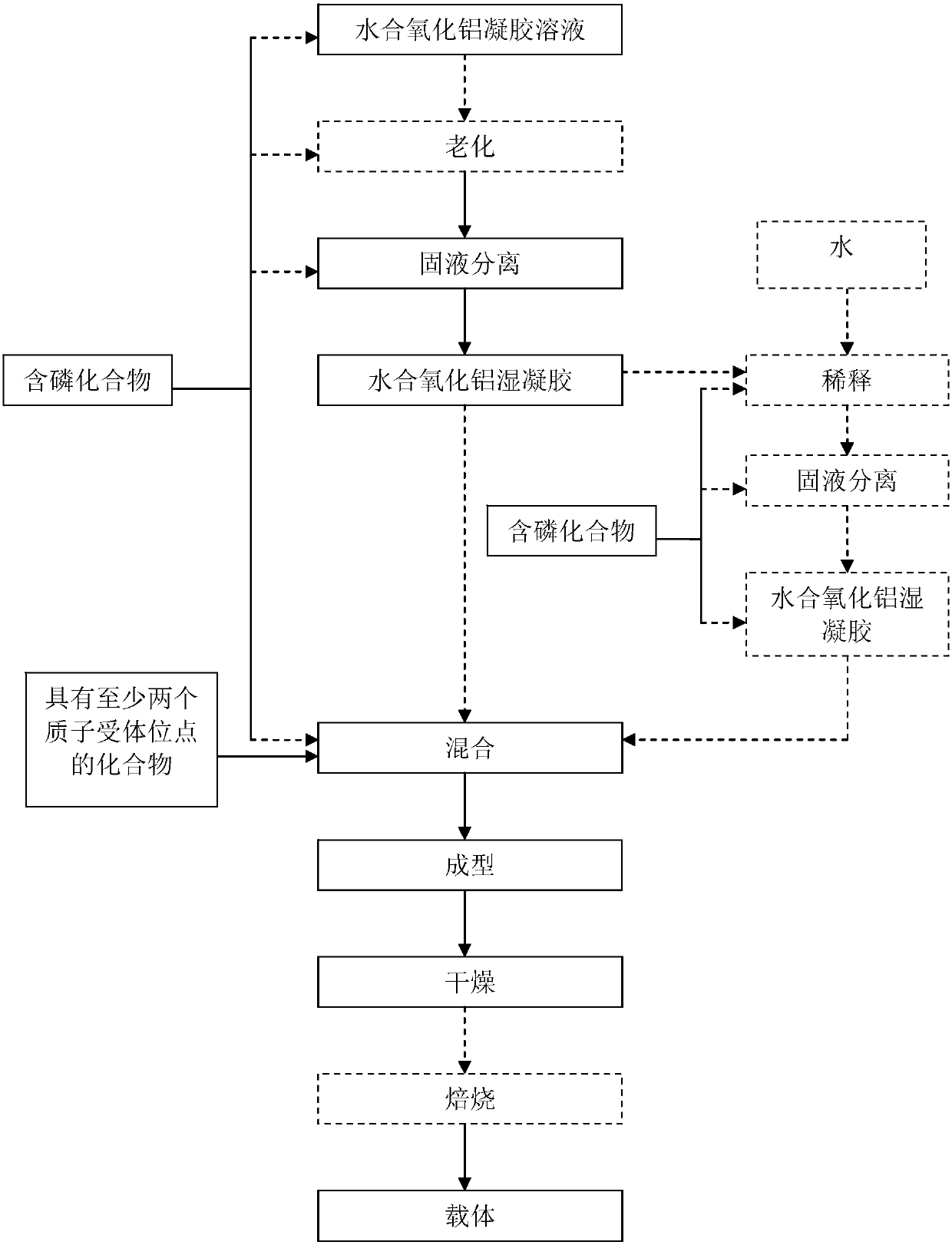

Catalyst having hydrogenation catalysis effect, preparation method and application thereof, and heavy oil hydrogenating and deasphaltenizing method

ActiveCN108014830ASimple processReduce operating energy consumptionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrated aluminaOperating energy

The invention relates to the technical field of hydrocarbon oil hydrogenation, and concretely discloses a catalyst having a hydrogenation catalysis effect, a preparation method and an application thereof, and a heavy oil hydrogenating and deasphaltenizing method. The catalyst contains a carrier and hydrogenation active components supported on the carrier, and the carrier is obtained through forming a hydrated alumina composition having a phi value being 1.8-5 and containing hydrated alumina, a compound having at least two proton acceptor sites and a phosphorus-containing compound. The invention also discloses the heavy oil hydrogenating and deasphaltenizing method using the catalyst. The carrier of the catalyst, having a high strength, is prepared from hydrated alumina wet gel, so the stepfor drying the hydrated alumina wet gel is omitted, the total process flow is simplified, the total operating energy consumption is reduced, dust pollution initiated by pseudo-boehmite dry glue powder used as a raw material to prepare the carrier is avoided, and the working environment is greatly improved. The catalyst has a high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

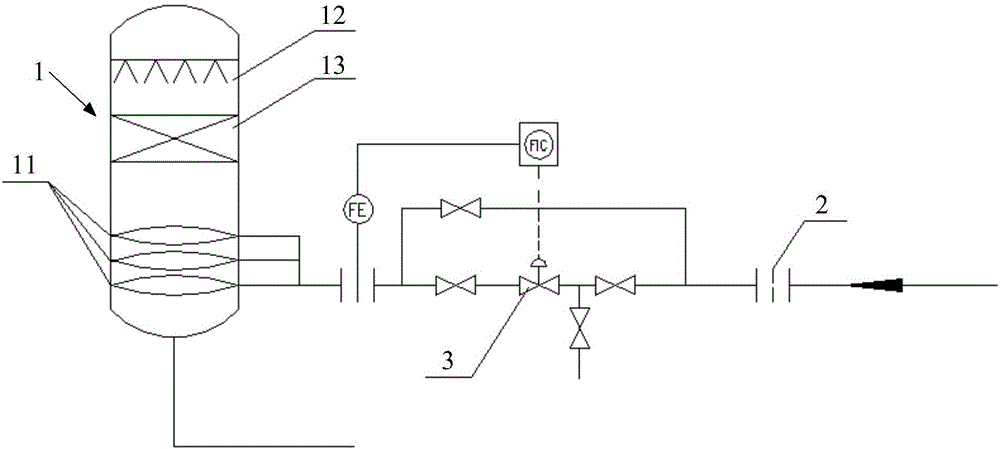

Production system and production method of aluminum foil machining liquid

ActiveCN106147858AControl Depth of RefiningImprove propertiesTreatment with hydrotreatment processesHydrocarbon oils treatment productsLiquid productDistillation

The invention discloses a production system of aluminum foil machining liquid. The production system comprises a hydrogenation isomerism and hydrogenation refining device, a fractionation device and a steam stripping tower, a flow adjusting valve and a restriction orifice are sequentially arranged on a stripping pipeline between the stripping tower and a stripping steam source, and the flow adjusting valve is arranged between the restriction orifice and the stripping tower. By the aid of the production system of the aluminum foil machining liquid, the dimension of breadth of product distillation range is accurately controlled, the light hydrocarbon recovering rate of a stripping stage is improved, product quality is improved, the temperature of a tower feeding material is reduced, the energy consumption of the devices is reduced, and tower thrusting accidents can be effectively avoided. The quality of aluminum foil machining liquid products prepared by the system is obviously improved, distillation range, viscosity, chromaticity and the like of oil products are improved, so that the performance requirements of the aluminum foil machining liquid in aluminum foil processing industries are met. The invention further discloses a production method of the aluminum foil machining liquid.

Owner:HAINAN HANDI SUNSHINE PETROCHEM

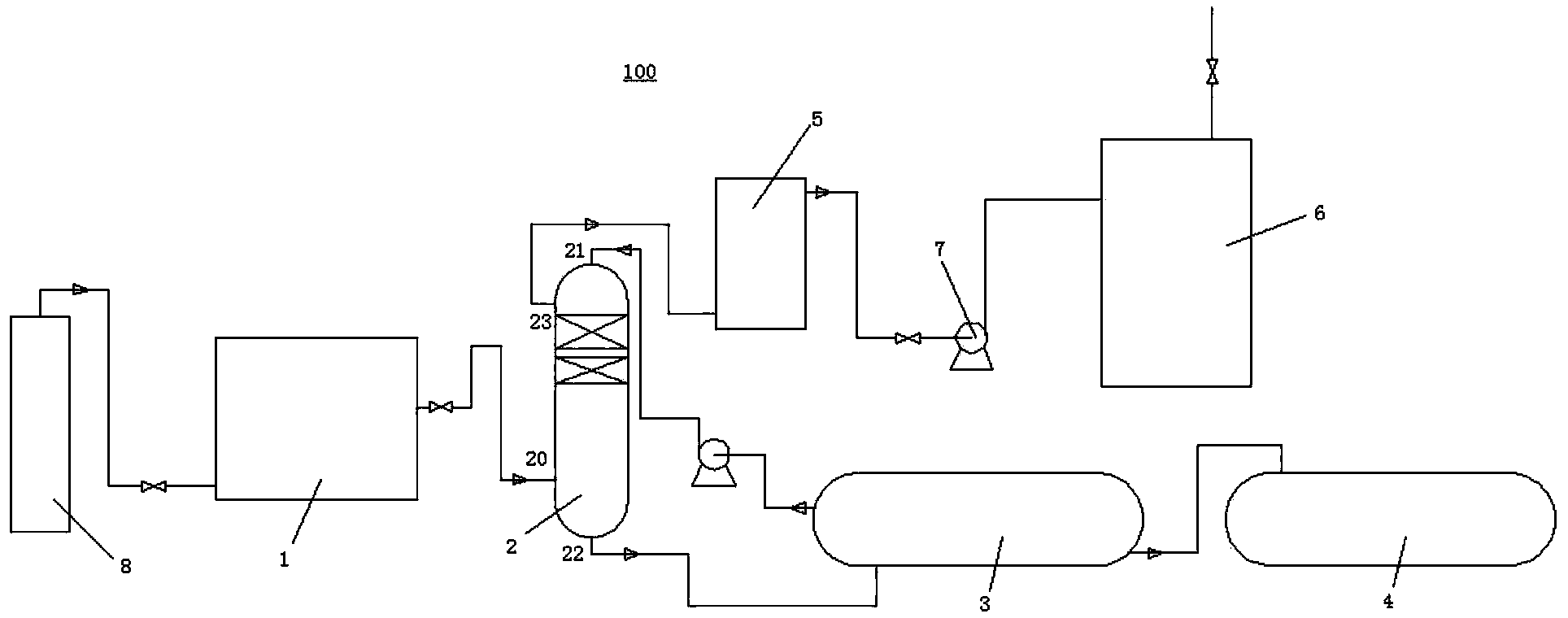

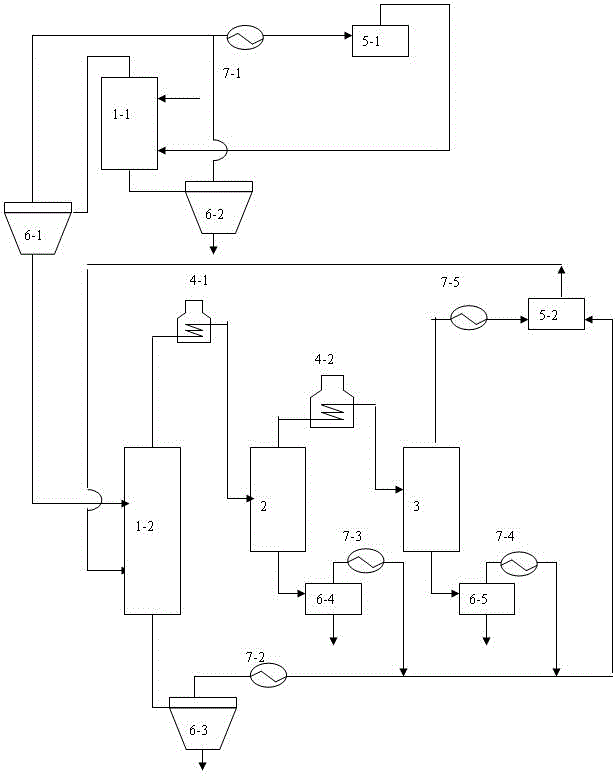

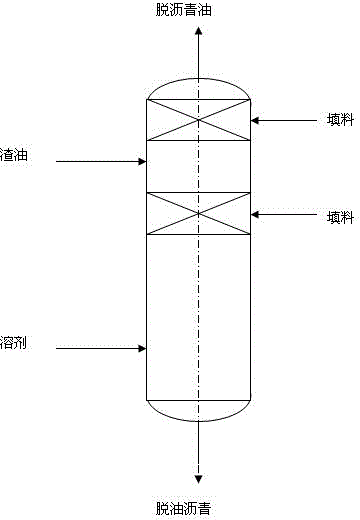

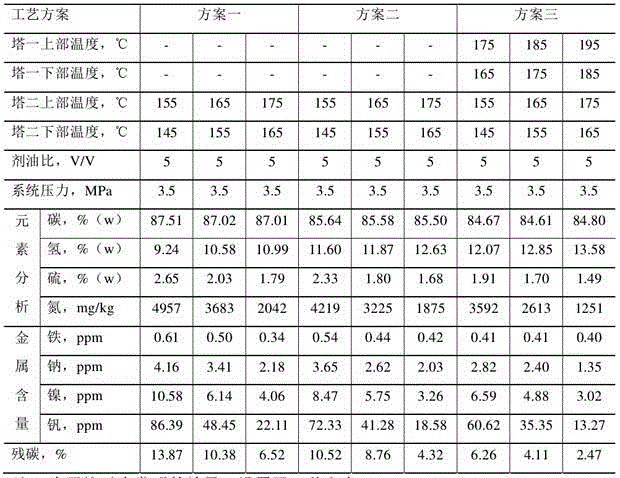

Inferior residual oil solvent extraction apparatus and processing technology thereof

ActiveCN105524649ALow asphaltene contentReduce solubilityTreatment with plural serial refining stagesFilling materialsResidual oil

The invention discloses an inferior residual oil solvent extraction apparatus and a processing technology thereof. The solvent extraction technology is characterized in that residual oil is extracted by using a solvent with several times of its volume and separated to obtain most asphaltene, secondary extraction on light components are carried out by using another solvent, asphaltene cannot be introduced into a subsequent pipeline, and deasphalted oil quality can be guaranteed. Multilayer filling materials are arranged on an extraction tower, multilayer filling materials are arranged in the extraction tower, increasing of asphaltene by following with a mixing solution can be avoided, asphaltene is retained in the extraction tower, introduction of the asphaltene into the subsequent pipeline can be avoided, and normal work of constant pressure device is influenced.

Owner:CHINA PETROLEUM & CHEM CORP +1

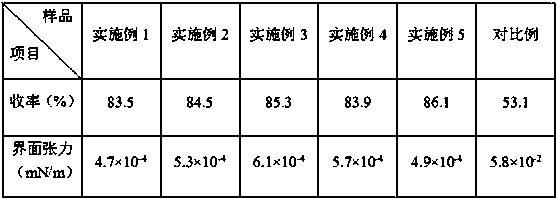

Petroleum sulfonate and preparation method thereof

InactiveCN109824552AHigh yieldLow asphaltene contentOrganic compound preparationSulfonic acids salts preparationHydrogenSulfur trioxide

The invention discloses petroleum sulfonate and a preparation method thereof. The petroleum sulfonate comprises a petroleum component, a catalyst, an alkali solution, hydrogen and sulfur trioxide. Thepreparation method of the petroleum sulfonate includes preparing a sulfonated raw material; performing primary sulfonation and extraction to obtain unsulfonated oil and an extracting agent containingpetroleum sulfonic acid; repeating sulfonation and extraction on the unsulfonated oil until no unsulfonated oil is obtained; combining and distilling the extracting agent containing the petroleum sulfonic acid to obtain the petroleum sulfonic acid; performing ageing and neutralizing to obtain a petroleum sulfonate solution, and concentrating and drying the petroleum sulfonate solution to obtain apetroleum sulfonate product. The petroleum sulfonate product has high good interfacial tension performance, a sulfonation reactor has less coking during preparation and long operating cycle, and thecost is reduced.

Owner:高路生

Hot mix plant recycling high-modulus asphalt mixture and preparation method thereof

ActiveCN112661440AIncrease profitIncreased stiffness modulusSolid waste managementHigh-density polyethyleneMeth-

The invention relates to the technical field of asphalt mixtures, in particular to a hot mix plant recycling high-modulus asphalt mixture and a preparation method thereof. The asphalt mixture comprises the following components in parts by weight: 40-50 parts of milled old materials, 1-4 parts of new asphalt, 35-50 parts of new aggregate, 1-6 parts of mineral powder and 1-4 parts of auxiliary agent, wherein the auxiliary agent comprises the following components in parts by weight: 30-40 parts of low-density polyethylene, 20-25 parts of high-density polyethylene, 13-16 parts of a methyl styrene block copolymer, 10-20 parts of polyacrylonitrile, 15-20 parts of a high modulus agent, 5-8 parts of a warm mixing agent and 10-15 parts of a regenerant. The invention aims to provide the hot mix plant recycling high-modulus asphalt mixture and the preparation method thereof. The asphalt mixture has relatively high stiffness modulus and stable performance.

Owner:重庆质能环保科技有限公司

Needle coke prepared from heavy oil and method thereof

The invention discloses needle coke prepared from heavy oil and a method thereof. The method comprises the following steps: selecting the heavy oil as a raw material; carrying out deliming treatment on the raw materials to obtain clarified oil; the clarified oil is separated by adopting a solid-liquid adsorption method, the polarity of an aluminum oxide stationary phase and the washing strength of a mobile phase are respectively adjusted according to different raw materials, a first mobile phase and a second mobile phase are subjected to gradient elution to obtain an aromatic-rich component, and the first mobile phase and the second mobile phase adopt a mixed or single solvent, preferably a mixed solvent; the aromatic-rich component is subjected to a first-stage carbonization reaction at low temperature and high pressure, and then is subjected to a second-stage carbonization reaction at high temperature and low pressure, so as to obtain a needle coke product. The preparation method provided by the invention has no harsh requirements on equipment, and the high-quality needle coke can be finally obtained.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com