Plant-mixed hot asphalt mixture and preparation method thereof

A technology for mixture and hot asphalt, applied in the field of factory-mixed hot asphalt mixture and its preparation, can solve the problems of large acid-base difference, reduced service life and easy occurrence of cracks in crushed natural sand and gravel aggregates, and is suitable for large-scale Chemical production, long service life, and the effect of improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

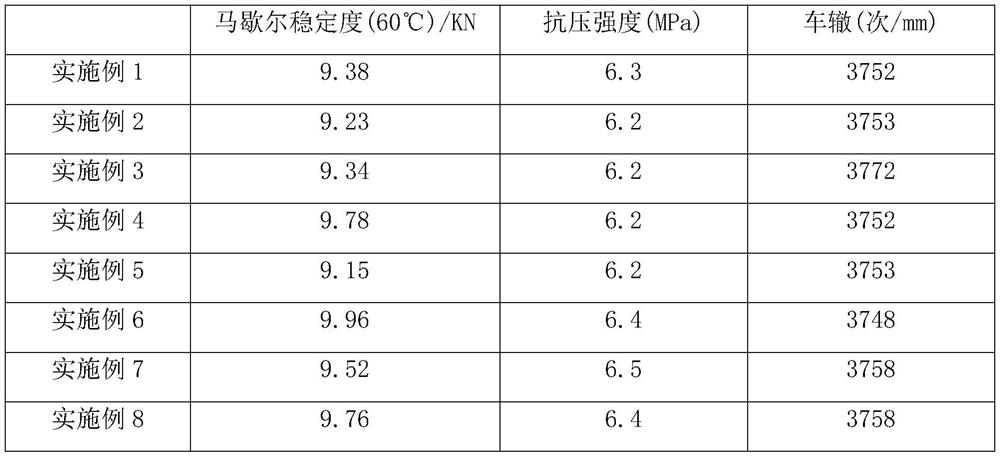

Examples

Embodiment 1

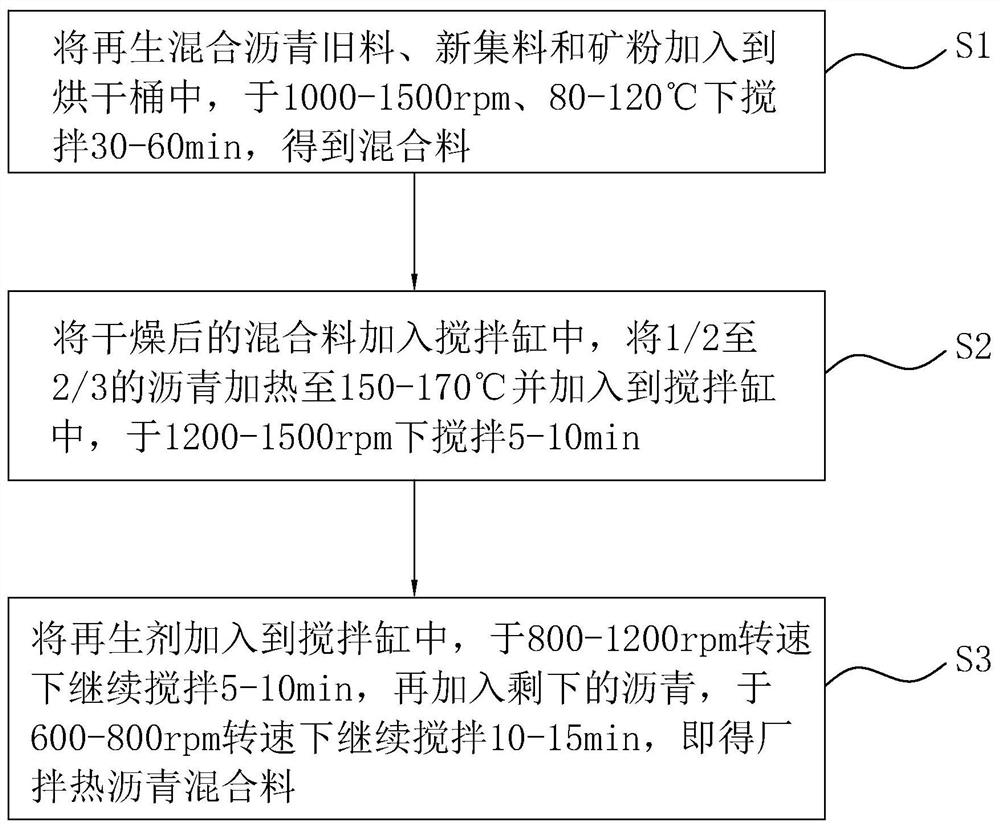

[0047] Embodiment 1: A kind of factory-mixed hot asphalt mixture, each component and its corresponding parts by weight are as shown in Table 1, such as figure 1 , and prepared by the following steps:

[0048] S1, add the recycled mixed asphalt old material, new aggregate and mineral powder into the drying barrel, and stir at 1000rpm and 80°C for 60min to obtain the mixture;

[0049] S2, add the dried mixture into the mixing tank, heat 1 / 2 of the asphalt to 150°C and add it into the mixing tank, and stir at 1200rpm for 10min;

[0050] S3, add the regenerant into the mixing tank, continue stirring at 800rpm for 10 minutes, then add the remaining asphalt, and continue stirring at 600rpm for 15 minutes to obtain the plant-mixed hot asphalt mixture.

[0051] The regenerated mixed asphalt old material in this embodiment is composed of old asphalt pavement materials with particle sizes ranging from 0 to 10 mm and 10 to 31.5 mm in a weight ratio of 0.8:1; the filler is silicon carbid...

Embodiment 2-6

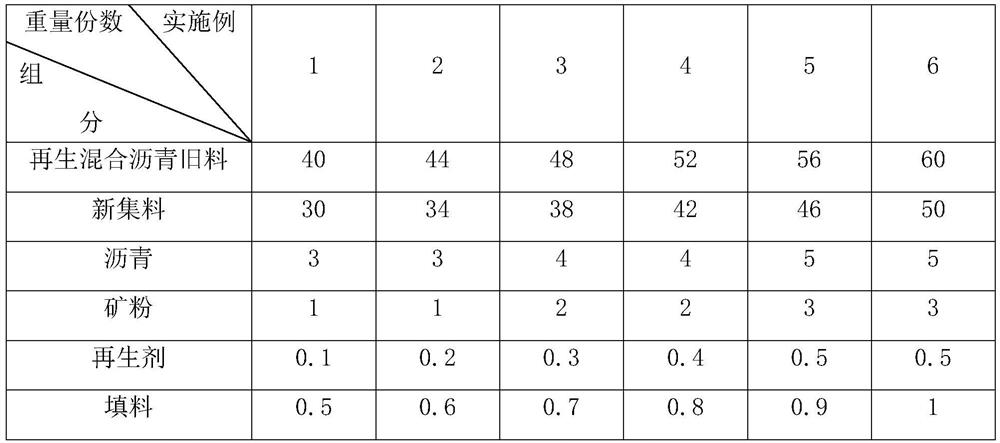

[0053] Example 2-6: A plant-mixed hot asphalt mixture, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0054] Each component and parts by weight thereof in table 1 embodiment 1-6

[0055]

Embodiment 7

[0056] Embodiment 7: A factory-mixed hot asphalt mixture, which is different from Embodiment 1 in that it is prepared through the following steps:

[0057] S1, add the recycled mixed asphalt old material, new aggregate and mineral powder into the drying barrel, and stir at 1350rpm and 100°C for 45min to obtain the mixture;

[0058] S2, add the dried mixture into the mixing tank, heat 2 / 3 of the asphalt to 160°C and add it into the mixing tank, and stir at 1350rpm for 7.5min;

[0059] S3, add the regenerant into the mixing tank, continue to stir at 1000rpm for 7.5min, then add the remaining asphalt, continue to stir at 700rpm for 12.5min, and get the plant-mixed hot asphalt mixture.

[0060] The regenerated mixed asphalt old material in this example is composed of old asphalt pavement materials with a particle size range of 0-10mm and 10-31.5mm in a weight ratio of 1:1; the filler is silicon carbide and glass in a weight ratio of 1:1 Mixture of microbeads.

[0061] The regene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com