Supercritical hydroextraction of kerogen from oil shale ores

a technology of oil shale ores and supercritical hydroextraction, which is applied in the petroleum industry, liquid hydrocarbon mixture production, etc., can solve the problems of reducing the asphaltene content of recycled and final product streams, and achieves simple leaching, high oil yield, and reduced gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

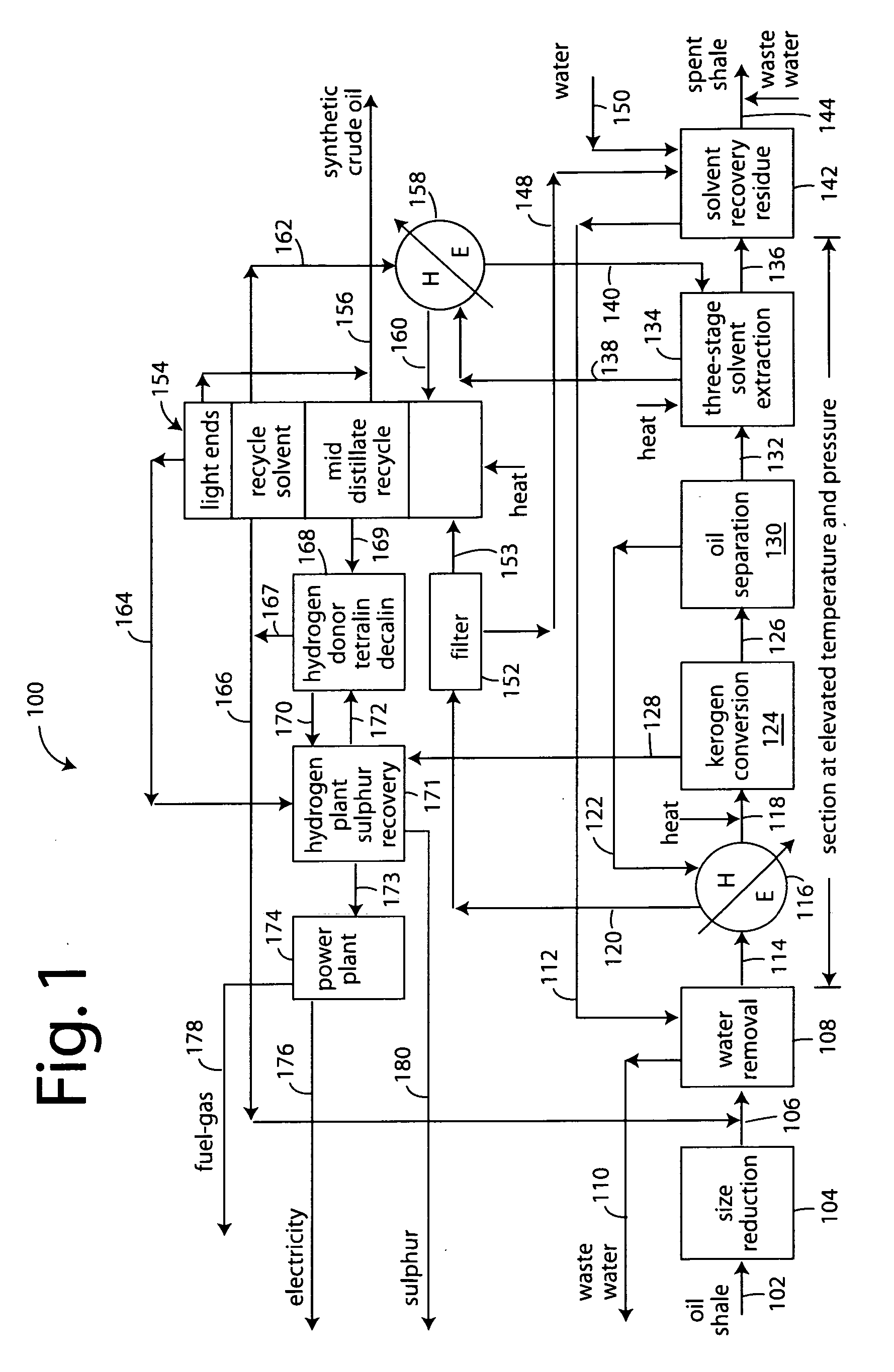

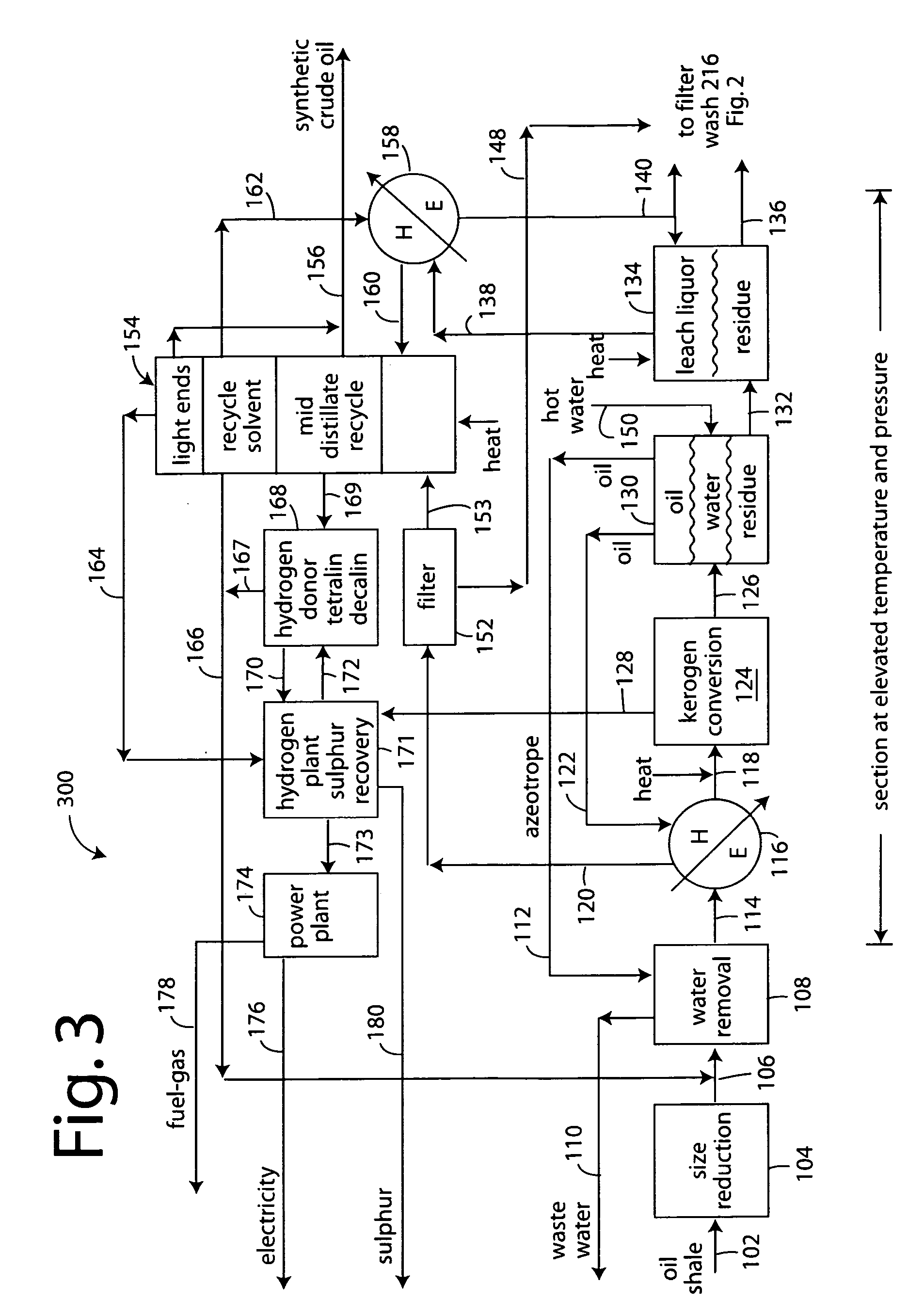

[0040] An oil shale ores processing plant embodiment of the present invention is diagrammed in FIG. 1 and is referred to herein by the general reference numeral 100. The principle product produced is synthetic crude oil that is suitable for pipeline transportation. An oil shale ores input feed 102 is crushed by a size reducer 104. Alternatively, the input feed 102 can comprise cannel coal, aka, “candle coal”, a type of coal with large amounts of hydrogen.

[0041] A crushed oil shale ores flow 106 is mixed with a recirculating solvent and input to a water remover 108. Any waste water 110 is removed from the system. A recovered solvent vapor flow 112 is added, condensed for heat recovery and a slurry flow 114 is output. A heat exchanger (H / E) 116 provides a recovered-heat flow 118 and outputs an oil product flow 120. Hot oil product flow 122 is received from further down the process and is stripped of its elevated heat for recovered-heat flow 118, and the remainder is the cooler oil pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com