Hot mix plant recycling high-modulus asphalt mixture and preparation method thereof

An asphalt mixture and thermal regeneration technology, applied in the field of asphalt mixture, can solve the problems of insufficient fusion of new and old asphalt, low stiffness modulus, etc., and achieve the effects of easy implementation, improved solubility, and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

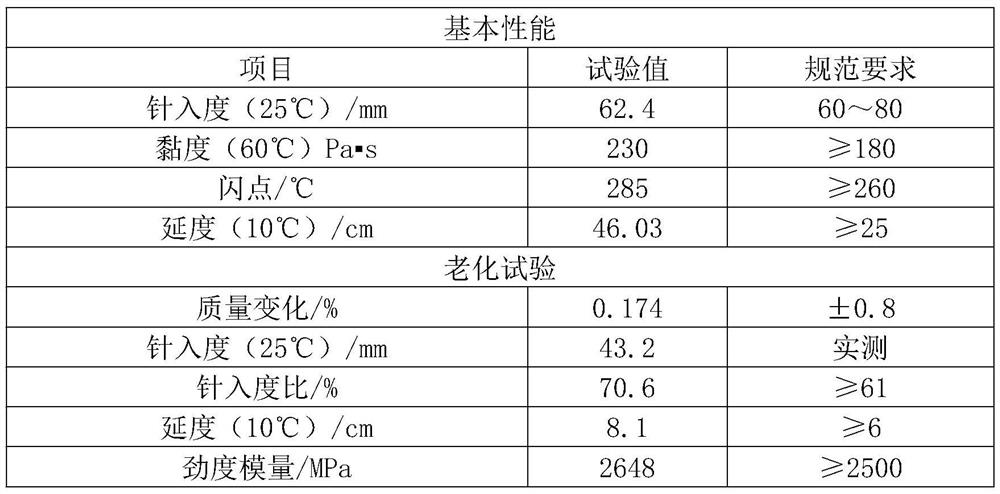

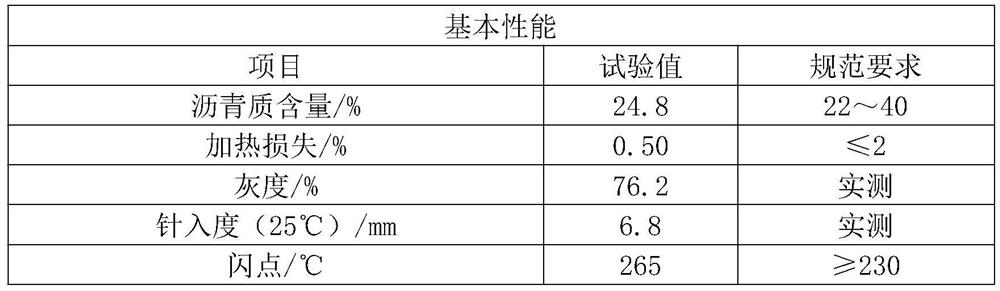

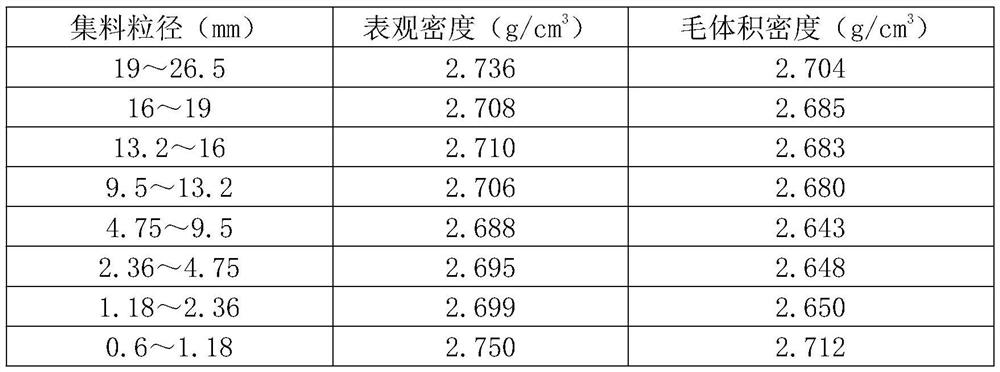

[0030] The old milling material in this embodiment is recovered by layered milling of the original asphalt pavement, crushed and processed into a suitable particle size, and then subjected to plant mixing and thermal regeneration.

[0031] Wherein, the factory-mixed hot-recycled high-modulus asphalt mixture of this embodiment includes the following components: in parts by weight, 40 parts of old milling material, 1 part of new asphalt, 35 parts of new aggregate, and 1 part of mineral powder and 1 part of auxiliary agent; said auxiliary agent includes the following components in parts by weight: 30 parts of low density polyethylene, 20 parts of high density polyethylene, 13 parts of methyl styrene block copolymer, 10 parts of polyacrylonitrile , 15 parts of high modulus agent, 5 parts of warm mixing agent and 10 parts of regeneration agent.

[0032] Specifically, the high modulus agent is formed by mixing epoxy resin, calcium sulfate whiskers and carboxymethyl cellulose calcium...

Embodiment 2

[0058] The preparation method of the asphalt mixture in this embodiment is the same as in Embodiment 1, and will not be repeated here.

[0059] In this embodiment, the asphalt mixture includes the following components: 50 parts of milling old material, 4 parts of new asphalt, 50 parts of new aggregate, 6 parts of mineral powder and 4 parts of auxiliary agent; wherein, the auxiliary agent includes the following Components in parts by weight: 40 parts of low density polyethylene, 25 parts of high density polyethylene, 16 parts of methyl styrene block copolymer, 20 parts of polyacrylonitrile, 20 parts of high modulus agent, 8 parts of warm mixing agent parts and 15 parts of regeneration agent.

Embodiment 3

[0061] The preparation method of the asphalt mixture in this embodiment is the same as in Embodiment 1, and will not be repeated here.

[0062] In this embodiment, the asphalt mixture includes the following components: 45 parts of milling old material, 3 parts of new asphalt, 40 parts of new aggregate, 5 parts of mineral powder and 3 parts of auxiliary agent; wherein, the auxiliary agent includes the following Components in parts by weight: 35 parts of low density polyethylene, 23 parts of high density polyethylene, 15 parts of methyl styrene block copolymer, 15 parts of polyacrylonitrile, 18 parts of high modulus agent, 7 parts of warm mixing agent 12 parts and regeneration agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com