Method and device for pretreating hydrogenation raw material by utilizing electric separation technology

A technology of electric separation and raw materials, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, and electric/magnetic refining, etc., which can solve the problems of hydrogenation raw material pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

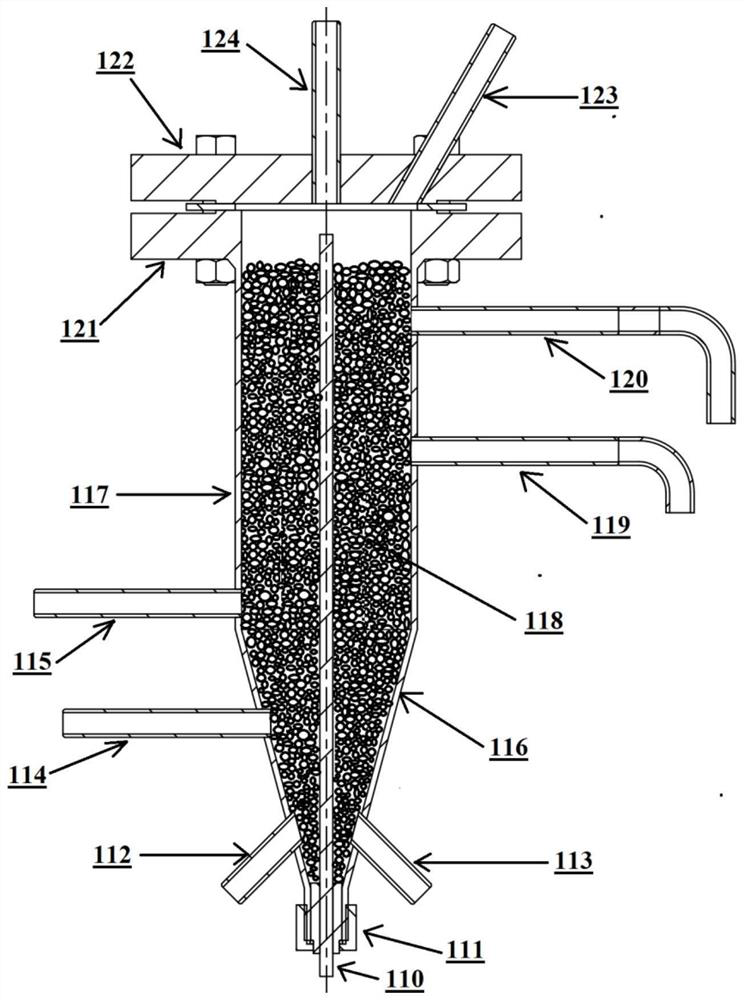

[0081] like figure 1 As shown, it is the electrical separation system in the device of the present invention, which includes a central high-voltage electrode 110, a high-voltage electrode insulation set 111, a residual oil outlet 112, a residual oil outlet 113, and a feed inlet 114. Feed inlet 2 115, conical feeder 116, separator container 117, packing bead bed 118, refined oil outlet 1 119, refined oil outlet 2 120, upper flange 121, upper flange cover 122, cleaning oil outlet 123 , the feed inlet three 124, wherein the upper flange 121, the separator container 117, and the conical feeder 116 form a pressure vessel, and the central high-voltage electrode 110 is arranged at the very center of the high-voltage electrode insulating set 111, and runs through the entire packing bead The bed 118, the height of the packed bead bed 118 is the same as the height of the central high voltage electrode 110. The central high-voltage electrode 110 is connected to an external high-voltage ...

Embodiment 2

[0087] The device shown in Example 1 was used to process the hydrogenation raw material A, wherein the properties of the hydrogenation raw material A are shown in Table 1.

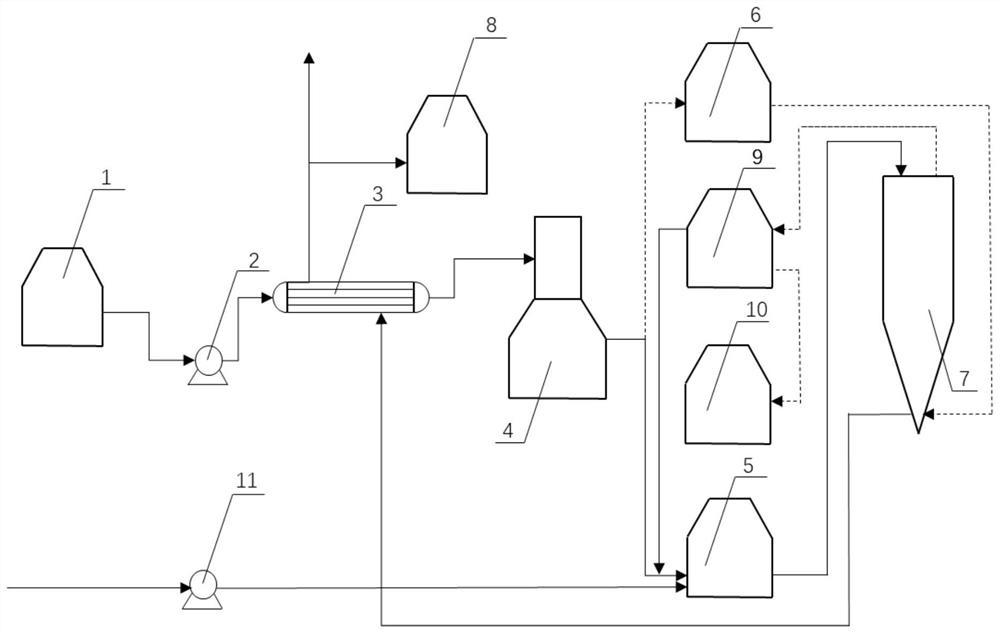

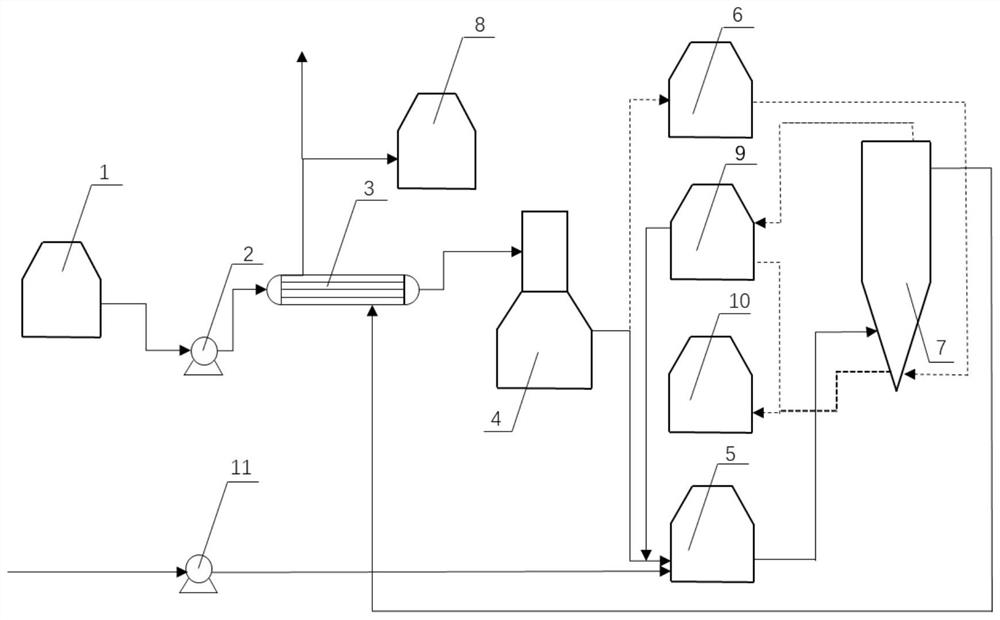

[0088] The electrical separation process is as follows: store the hydrogenation raw material A in the hydrogenation raw material storage tank 1, keep the temperature at 120°C, transport it to the refined oil heat exchanger 3 through the feed pump 2 for heat exchange to 210°C, and then enter the preheater 4, further heated to 280°C. Part of the preheated hydrogenation raw material A is sent to the backwash oil buffer tank 6, and the temperature is maintained at 270°C; the other part is sent to the hydrogenation raw material buffer tank 5, and the temperature is maintained at 270°C. The hydrogenation raw material A in the hydrogenation raw material buffer tank 5 enters the electric separation system 7, and the flow rate of the hydrogenation raw material A entering the electric separation system 7 is 35m 3 / ...

Embodiment 3

[0102] The device shown in Example 1 was used to process the hydrogenation raw material, and the hydrogenation raw material A in Example 2 was used, and the electrical separation process was the same as in Example 2.

[0103] The packing ratio, feeding method and backwashing method in the separator are as follows:

[0104]In the present embodiment condition (1), the filler used in the filler bead bed 122 is glass microspheres produced by a certain glass bead product factory in China, 80% of which are in the diameter range of 0.8-1.5mm, and 20% are in the diameter range of 1.5-1.5 mm. Within 2.5 mm, the hydrogenation raw material A feed enters the separator 117 from the feed inlet 114, and the refined oil after electrical separation flows out of the separator 117 from the refined oil outlet 120, while the residue oil with a relatively high content of asphaltene is discharged from the residue The oil outlet one 112 flows out of the separator 117 and is sent to the residue storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com