Solid-liquid separation device for oil slurry and solid-liquid separation system for oil slurry

A technology of solid-liquid separation and oil slurry, which is applied in the direction of filtration separation, separation method, and treatment of hydrocarbon oil, etc. It can solve the problem that the filtration separation process is difficult to meet the long-term stable work, there is no major technical improvement in swirling and filtration, and the process flow unequal problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

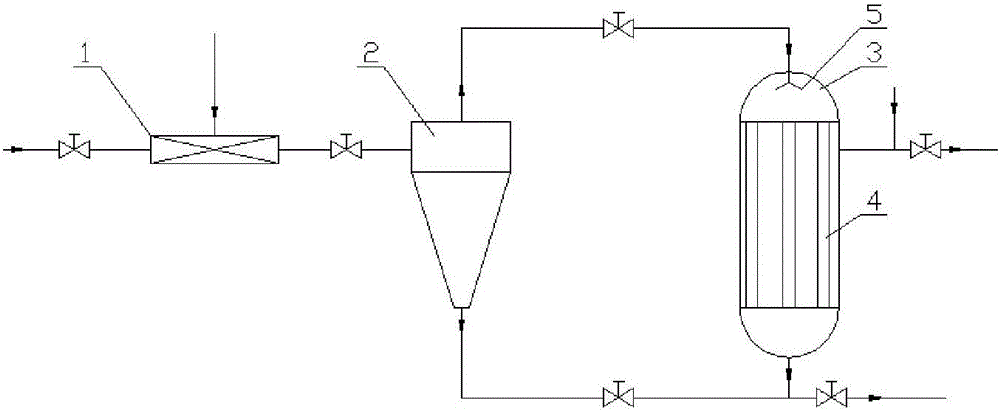

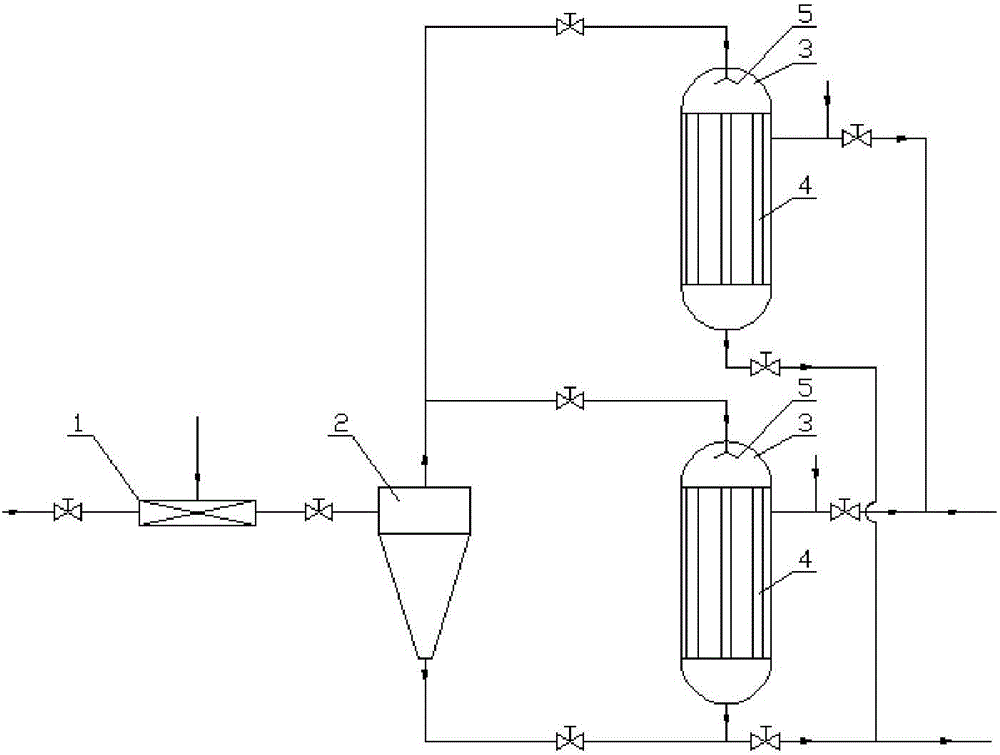

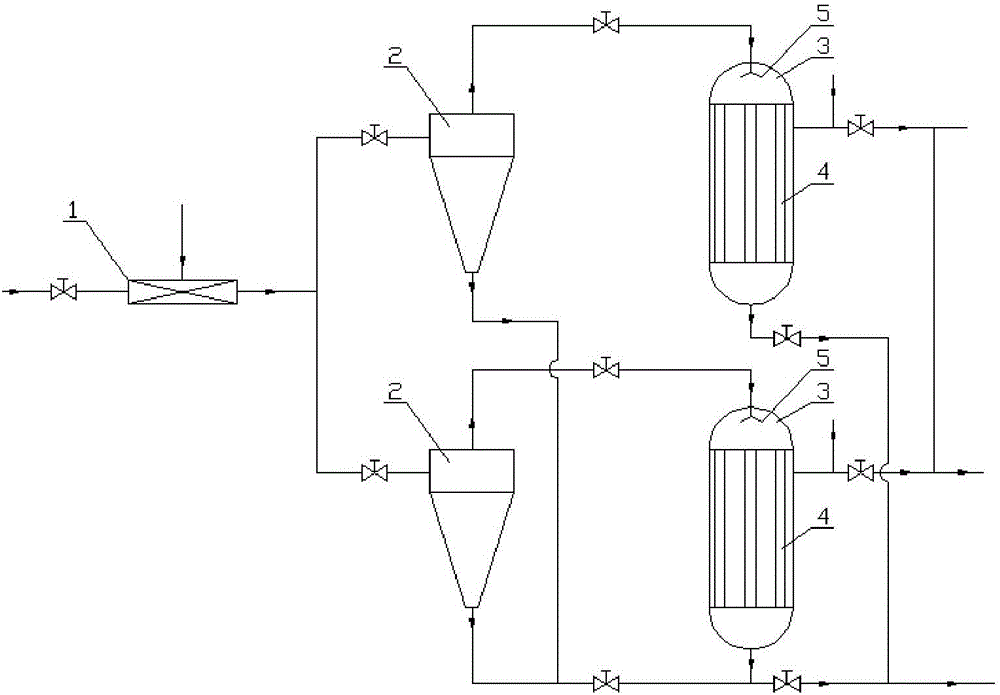

[0036] Such as figure 1 -3, the slurry solid-liquid separation device provided in this embodiment includes at least one mixer 1, at least one primary separator 2 connected to each mixer 1, and connected to each primary separator 2 Pass through at least one secondary filter 3 .

[0037] It should be pointed out here that the purpose of the mixer 1 and the primary separator is to ensure that the filter will not be contaminated with colloid-rich oil slurry and that the filter tube will not be blocked. At the same time, with the help of cross-flow filtration technology, the entire system can basically Realize continuous work without backwashing.

[0038] Specifically, each specific structure of the slurry solid-liquid separation device in this embodiment will be described in detail below:

[0039] For mixer 1, it is an auxiliary mixer.

[0040] It should be pointed out that the auxiliary agent mixer can be a conventional static mixer, or a Venturi ejector, preferably a Venturi ej...

Embodiment approach

[0048] Such as figure 1 As shown, in the first alternative of this embodiment, a mixer 1, a primary separator 2 and a secondary filter 3 are included; the mixer 1 communicates with the primary separator 2, and the The primary separator 2 communicates with the secondary filter 3;

[0049] Such as figure 2 As shown, in the second alternative of this embodiment, a mixer 1, a primary separator 2 and two secondary filters 3 are included; the mixer 1 communicates with the primary separator 2, The primary separator 2 is in communication with the two secondary filters 3;

[0050] Such as image 3 As shown, in the third alternative of this embodiment, a mixer 1, two primary separators 2 and two secondary filters 3 are included; the mixer 1 and the two primary separators 2 The two primary separators 2 communicate with the two secondary filters 3 respectively.

[0051] It should be pointed out that in this embodiment, the number and combinations of the mixer 1, the primary separato...

Embodiment 2

[0055] On the basis of Embodiment 1, this embodiment also provides an oil slurry solid-liquid separation system, including the above-mentioned oil slurry solid-liquid separation device.

[0056] In this implementation, the oil slurry solid-liquid separation system also includes an automatic control system (not shown) on the basis of all mentioned oil slurry solid-liquid separation devices in the first embodiment. The automatic control system is electrically connected with the solenoid valve, which can Automatically adjust the opening and closing of the solenoid valve to improve the working efficiency of the system and save labor.

[0057] The oil slurry solid-liquid separation system provided in this embodiment includes the above-mentioned oil slurry solid-liquid separation device, so it has all the advantages of the oil slurry solid-liquid separation device, and will not be described in detail here.

[0058] To sum up, the purpose of auxiliary aid and first-stage separation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com