Liquid-phase hydrogenation reactor and hydrogenation process

A technology of liquid-phase hydrogenation and hydrogenation reaction, which is applied in the fields of hydrogenation treatment process, sustainable manufacturing/processing, petroleum industry, etc., and can solve problems such as difficult process control, reduced reaction conversion rate, and large temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

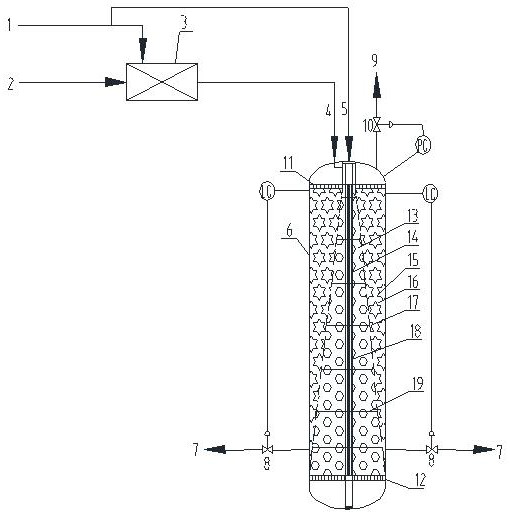

[0049] Attached figure 1 In the method described, the catalyst used in the conical inner cylinder of the liquid-phase hydrogenation reactor is FHDO-18 of the Fushun Petrochemical Research Institute, and the catalyst used in the annular cavity is FHDO-10; the feed of the liquid-phase hydrogenation reactor contains The hydrogen in the liquid-phase hydrogenation reactor is 0.015% of the mass of the raw material oil, and the amount of hydrogen supplemented by the hydrogen diffusion component of the liquid-phase hydrogenation reactor is 0.112% of the mass of the feedstock oil; the reaction conditions of the conical inner cylinder of the liquid-phase hydrogenation reactor are as follows: The temperature is 121.2~124.7℃, the reaction pressure is 1.8MPaG, and the liquid hourly volume space velocity is 15.0h -1 ;The reaction conditions of the annular cavity are as follows: the reaction temperature is 124.7~128.1°C, the reaction pressure is 1.75MPaG, and the liquid hourly volume space v...

Embodiment 2

[0053] Attached figure 1 In the method described, the catalyst used in the conical inner cylinder of the liquid-phase hydrogenation reactor is FHDO-10 of the Fushun Petrochemical Research Institute, and the catalyst used in the annular cavity is FHDO-6; the liquid-phase hydrogenation reactor feed contains The hydrogen is 0.012% of the mass of the feedstock oil, and the amount of hydrogen supplemented by the hydrogen diffusion component of the liquid-phase hydrogenation reactor is 0.117% of the mass of the feedstock oil. The reaction conditions of the conical inner cylinder of the liquid phase hydrogenation reactor are as follows: the reaction temperature is 122.4-125.8°C, the reaction pressure is 1.8MPaG, and the liquid hourly volume space velocity is 12.0h -1 ;The reaction conditions of the annular cavity are as follows: the reaction temperature is 125.8-129.2°C, the reaction pressure is 1.75MPaG, and the liquid hourly volume space velocity is 8.8h -1 . The ratio of the top...

Embodiment 3

[0057] Attached figure 1 In the method described, the catalyst used in the conical inner cylinder of the liquid-phase hydrogenation reactor is FHDO-18 of the Fushun Petrochemical Research Institute, and the catalyst used in the annular cavity is FHDO-6; the liquid-phase hydrogenation reactor feed contains The hydrogen is 0.025% of the quality of the raw material oil, and the hydrogen replenishment amount of the hydrogen diffusion component of the liquid phase hydrogenation reactor is 0.104% of the quality of the raw material oil. The reaction conditions of the conical inner cylinder of the liquid phase hydrogenation reactor are as follows: the reaction temperature is 120.7-124.2°C, the reaction pressure is 1.8MPaG, and the liquid hourly volume space velocity is 12.0h -1 ;The reaction conditions of the annular cavity are as follows: the reaction temperature is 124.2-127.5°C, the reaction pressure is 1.75MPaG, and the liquid hourly volume space velocity is 6.0h -1 . The ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com