Non-noble metal catalyst for preparing succinic anhydride by liquid-phase continuous hydrogenation of maleic anhydride and preparation method of non-noble metal catalyst

A technology of succinic anhydride and non-precious metals, which is applied in the field of non-precious metal catalysts and their preparation, can solve the problems of unsatisfactory market demand, large solvent circulation, high catalyst cost, etc., and achieves accelerated hydrogenation reaction rate, simple preparation process, and improved The effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

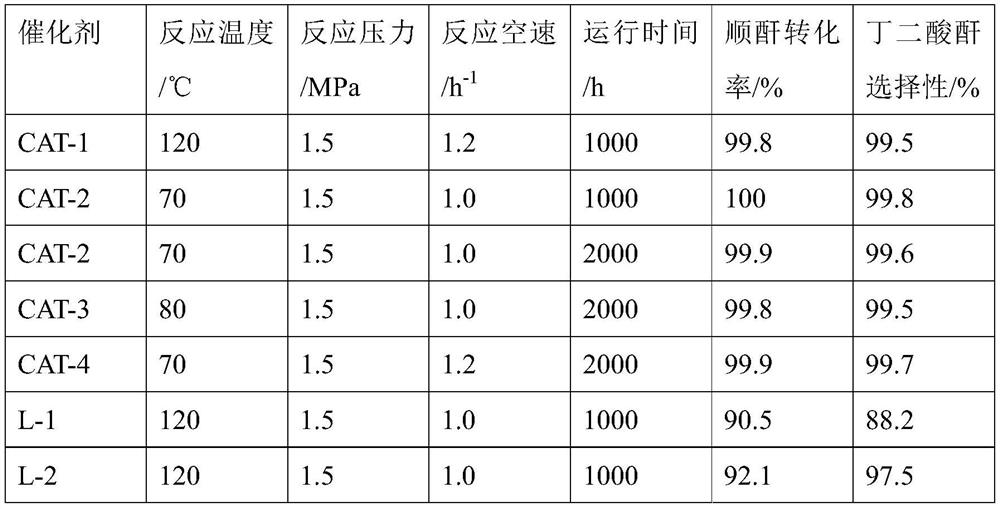

Examples

Embodiment 1

[0034] 1. Take 38.9g nickel nitrate hexahydrate, 12.1g copper nitrate trihydrate, 2.2g potassium nitrate, 4.7g citric acid and 5.5g nitric acid and add water to prepare 190ml active metal colloid solution, weigh 156g pseudo-boehmite on a dry basis Mix evenly with 6.2g of scallop powder, add active metal colloid solution, knead, extrude, and cut into pellets to obtain wet carrier; firstly cure the wet carrier for 12 hours, then dry it in an oven at 120°C for 4 hours, and finally place it in a muffle furnace Calcined at a constant temperature of 500°C for 4 hours to obtain a support containing nickel-copper active components.

[0035] 2. Take 116.8g of nickel nitrate hexahydrate and 2.7g of lanthanum nitrate hexahydrate and add water to prepare an impregnating solution, spray the impregnating solution evenly on the above-mentioned carrier by equal volume method, first dry it naturally, then dry it in an oven at 120°C for 4 hours, and finally Placed in a muffle furnace at a const...

Embodiment 2

[0038] 1. Take 54.5g of nickel nitrate hexahydrate, 24.3g of copper nitrate trihydrate, 12.7g of magnesium nitrate hexahydrate, 4.7g of citric acid and 5.5g of nitric acid and add water to prepare 172ml of active metal colloid solution, and weigh 140g of pseudo thin water on a dry basis Mix bauxite and 6.2g squat powder evenly, add active metal colloid solution, knead, extrude, and cut into pellets to get wet carrier; wet carrier is first cured for 12 hours, then dried in an oven at 120°C for 4 hours, and finally placed in a muffle Roasting at a constant temperature of 550° C. for 4 hours in a furnace to obtain a carrier containing nickel-copper active components.

[0039] 2. Take 140.1g of nickel nitrate hexahydrate and 2.5g of cerium nitrate hexahydrate and add water to prepare the impregnating solution. Spray the impregnating solution evenly on the above-mentioned carrier by equal volume method, first dry it naturally, then dry it in an oven at 120°C for 4 hours, and finally...

Embodiment 3

[0042] 1. Take 54.5g of nickel nitrate hexahydrate, 24.3g of copper nitrate trihydrate, 8.4g of calcium nitrate tetrahydrate, 4.7g of citric acid and 5.5g of nitric acid and add water to prepare 172ml of active metal colloid solution, and weigh 140g of pseudo-thin water on a dry basis Mix bauxite and 6.2g squat powder evenly, add active metal colloid solution, knead, extrude, and cut into pellets to get wet carrier; wet carrier is first cured for 12 hours, then dried in an oven at 120°C for 4 hours, and finally placed in a muffle Roasting at a constant temperature of 550° C. for 4 hours in a furnace to obtain a carrier containing nickel-copper active components.

[0043] 2. Take 140.1g of nickel nitrate hexahydrate, 1.3g of cerium nitrate hexahydrate and 1.4g of lanthanum nitrate hexahydrate and add water to prepare the impregnating solution. Spray the impregnating solution evenly on the above-mentioned carrier by equal volume method, first dry it naturally, and then put it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com