Coal direct hydro-liquefaction method

A hydrogenation liquefaction, direct technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of thick reactor wall, difficult manufacturing, high cost, etc., to shorten the reaction time, improve the utilization rate, and avoid manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

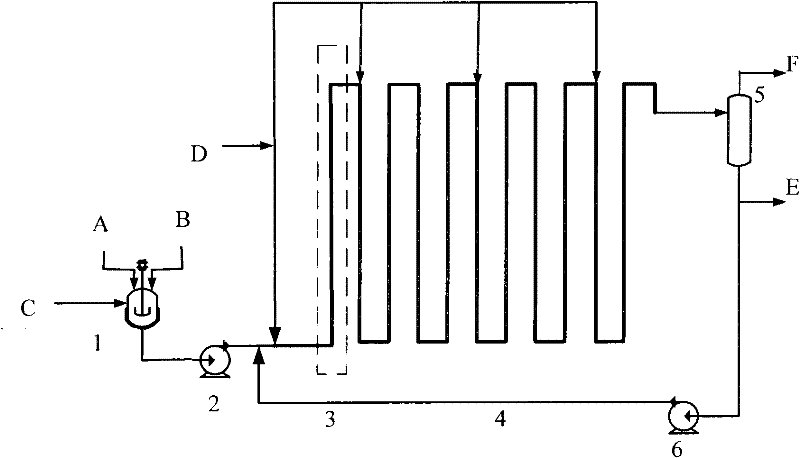

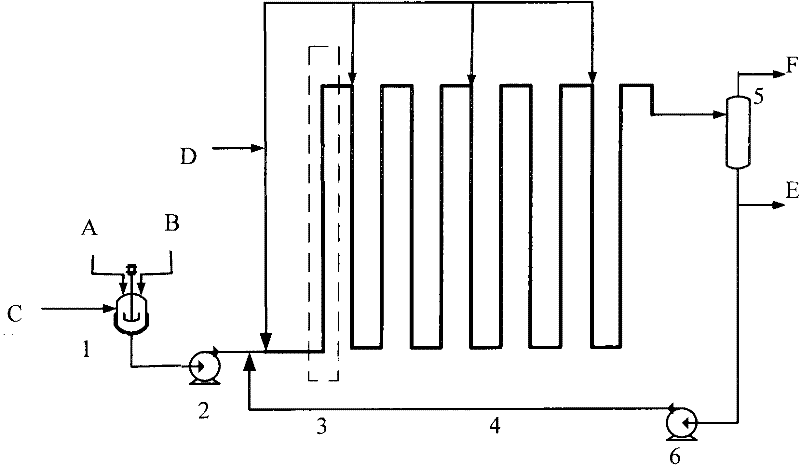

[0031] use figure 1 As shown in the process flow, the above-mentioned coal sample is dried and pulverized into coal powder of about 200 meshes, mixed with Shengli heavy oil and catalyst, the mixing ratio is coal: heavy oil: catalyst = 55:43:2 (weight ratio), at 160°C After swelling by stirring for 20 minutes, a stable and pumpable oil-coal slurry was formed. The oil-coal slurry is sent into a tubular reactor at a flow rate of 10,000kg / h using a high-pressure pump. The flow state in the tubular reactor is turbulent, with a diameter of Φ55mm, a length of 500m, and a reaction temperature of 380-460°C , the hydrogen partial pressure is 20MPa. Hydrogen is respectively from the entrance of the tubular reactor, 60m (accounting for 12% of the total length), 150m (accounting for 30% of the total length), 250m (accounting for 50% of the total length) and 350m (accounting for 70% of the total length) from the entrance of the tubular reactor Injection at five points, the amount of injec...

Embodiment 2

[0036] use figure 1 As shown in the process flow, the above-mentioned coal sample is dried and pulverized into coal powder of about 200 mesh, mixed with Shengli heavy oil and catalyst, the mixing ratio is coal: heavy oil: catalyst = 40:57:3 (weight ratio), at 160°C After swelling by stirring for 20 minutes, a stable and pumpable oil-coal slurry was formed. The oil-coal slurry is sent into a tubular reactor at a flow rate of 20,000kg / h using a high-pressure pump. The flow state in the tubular reactor is turbulent, with a diameter of Φ219mm, a length of 250m, and a reaction temperature of 380-460°C , the hydrogen partial pressure is 20MPa. Hydrogen respectively from the entrance of the tubular reactor, 40m (accounting for 16% of the total length), 90m (accounting for 36% of the total length), 150m (accounting for 60% of the total length) and 200m (accounting for 80% of the total length) from the entrance of the tubular reactor Injection at 5 points, the amount of hydrogen inje...

Embodiment 3

[0038] use figure 1 As shown in the process flow, the above-mentioned coal sample is dried and pulverized into coal powder of about 200 meshes, mixed with Shengli heavy oil and catalyst, the mixing ratio is coal: heavy oil: catalyst = 25:67:8 (weight ratio), at 160°C After swelling by stirring for 20 minutes, a stable and pumpable oil-coal slurry was formed. The oil-coal slurry is sent into a tubular reactor at a flow rate of 60,000kg / h using a high-pressure pump. The flow state in the tubular reactor is turbulent, with a diameter of Φ450mm, a length of 90m, and a reaction temperature of 380-460°C , the hydrogen partial pressure is 10MPa. Hydrogen is respectively from the tubular reactor entrance, 9m (accounting for 10% of total length) and 45m (accounting for 50% of total length) from entrance, and the amount of injected hydrogen is respectively 1% by weight, 0.7% by weight, 0.2% by weight of oil-coal slurry. % by weight, the reactor outlet material enters the high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com