Natural gas liquefaction system based on propane and iso-butane mixed pre-cooling

A technology of isobutane and natural gas, applied in the field of natural gas liquefaction system, can solve the problems of cumbersome process, high cost of liquefaction process, high energy consumption, etc., and achieve the effect of improving cooling efficiency, increasing energy exchange rate and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

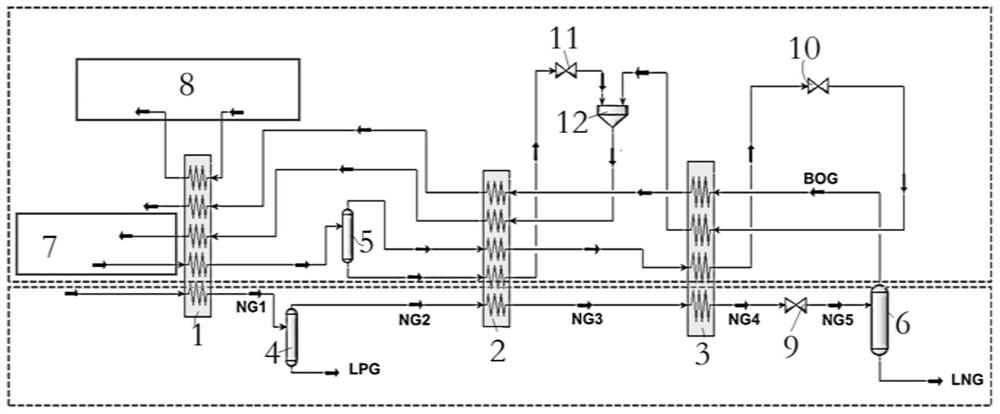

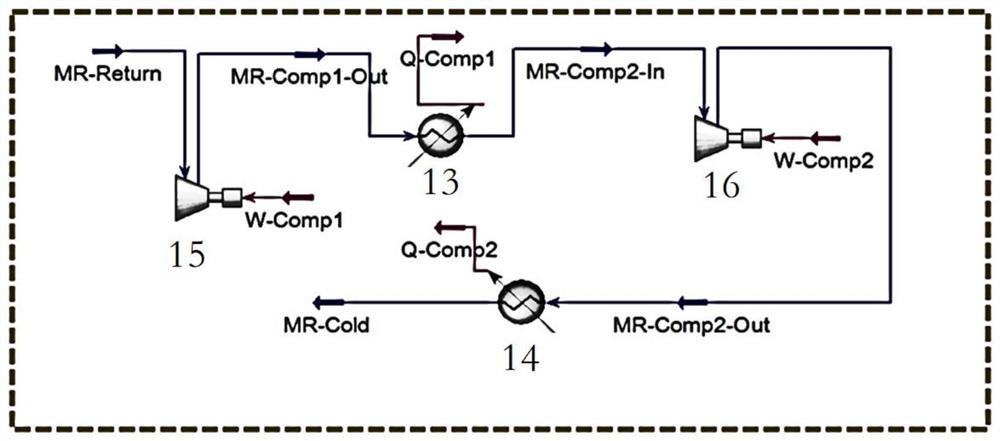

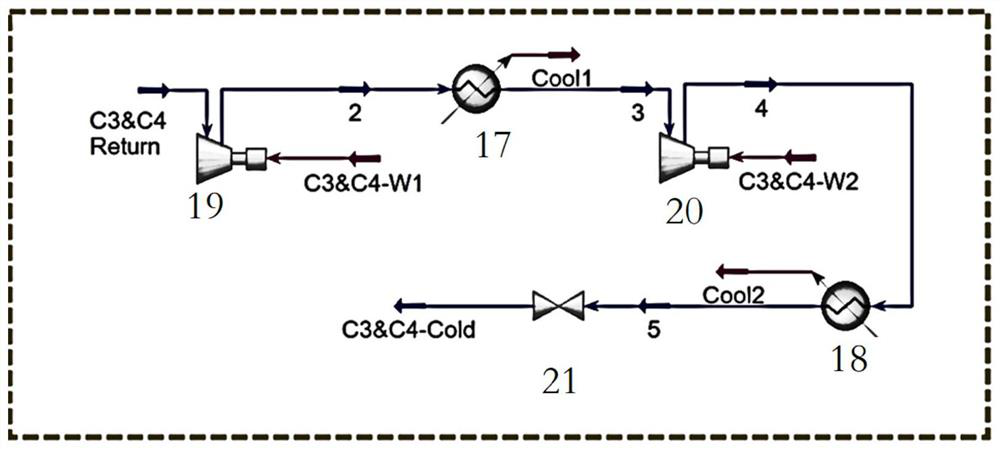

[0044] Such as Figure 1 to Figure 3 As shown, the mixed refrigerant liquefaction process using propane and isobutane mixed precooling,

[0045] The mixed precoolant output from the mixed precoolant compression skid enters the first heat exchanger 1, and the liquefied natural gas flows into the first heat exchanger 1 for precooling. The temperature after precooling is -35℃~-60℃, and the liquid The heavy hydrocarbon components are separated as LPG products, while the gaseous NG2 enters the second heat exchanger 2 and the third heat exchanger 3 for liquefaction and cooling, and the gas phase stream enters the second heat exchanger 2 to cool down to -100℃~-130℃ , the pressure of the stream NG5 flowing out of the first throttle valve is 200kPa, and the temperature is 113K. After being separated by the third gas-liquid separator 6, the liquid phase is LNG product, and the separated low-temperature gas phase BOG flows through the third heat exchanger 3. The second heat exchanger 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com