Internal combustion heating moving-bed type biomass pyrolysis liquefying apparatus

A biomass pyrolysis and liquefaction device technology, applied in the field of pyrolysis liquefaction devices, can solve the problems of limited heat, unavoidable shortcomings of reactors and methods, etc., and achieve the goal of improving utilization rate, reducing residence time, and increasing the calorific value of bio-oil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

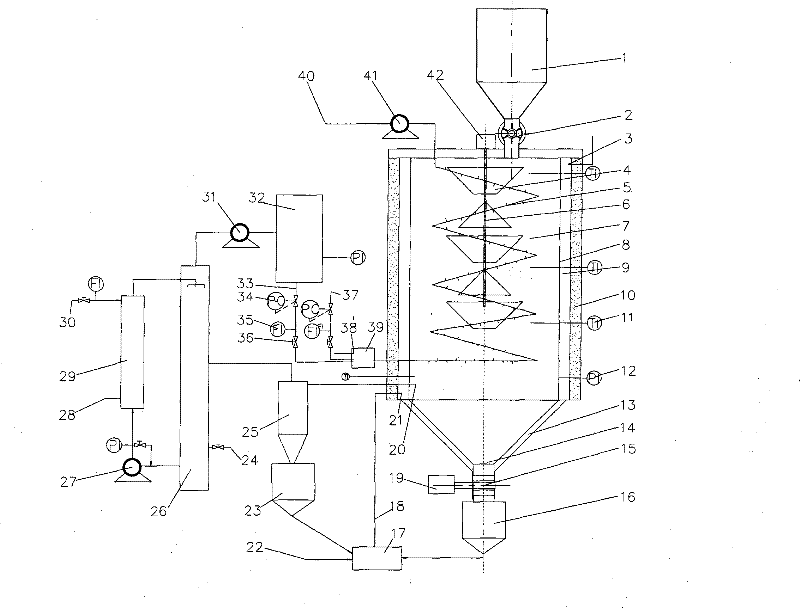

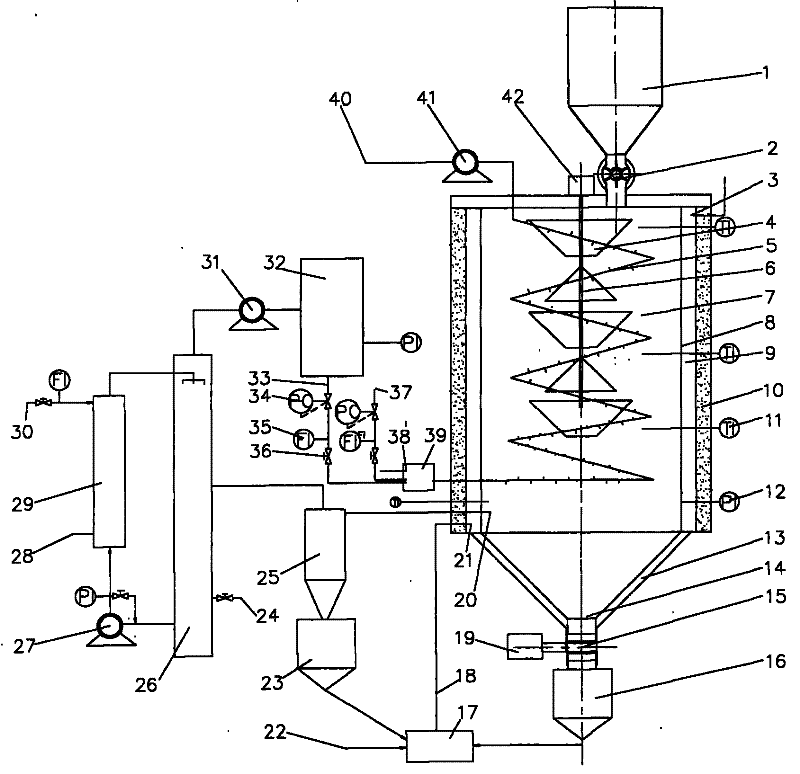

[0032] see figure 1 , the present embodiment adopts the cylindrical reactor 7, and in the inside of the cylindrical reactor 7, a serpentine internal combustion pipeline 5 is arranged, and the entrance of the serpentine internal combustion pipeline 5 is positioned at the bottom of the cylindrical reactor 7, and its outlet is from the cylinder. The top of the tubular reactor 7 extends to the outside of the reactor;

[0033] On the top of the cylindrical reactor 7, a blanking control valve 2 is set, and the feeding port is located at the top eccentric position of the cylindrical reactor 7, and on the central axis of the cylindrical reactor 7, a cone with a cone is set. The rotating shaft 6 of the funnel 4, and there is a conical distributing umbrella between the conical funnels 4, so that the biomass flowing out from the previous conical funnel 4 flows to the next conical funnel after being dispersed by the conical distributing umbrella 4, the residence time of biomass in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com