Method for preparing biological oil from algae biomass through direct catalytic liquefaction method

A technology for catalytic liquefaction and biomass, which is used in the preparation of liquid hydrocarbon mixtures and the petroleum industry. Relative effect of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

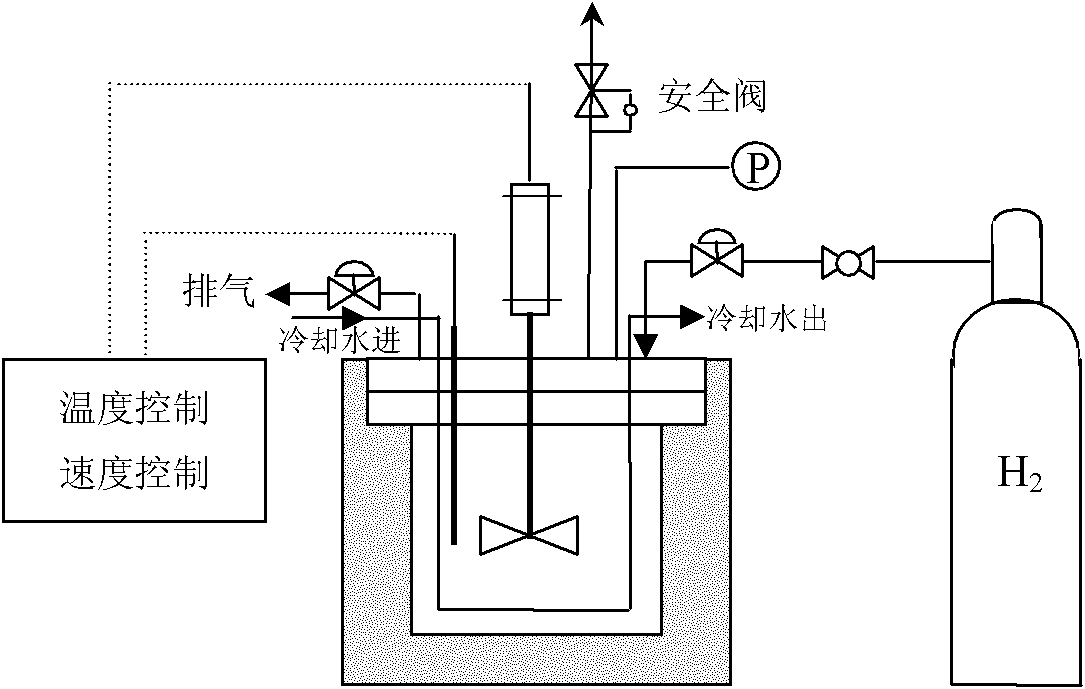

Image

Examples

Embodiment Construction

[0026] Non-limiting examples are described as follows:

[0027] (1) Raw material preparation

[0028] Collect Chaohu cyanobacteria or marine algae Enteromorpha biomass, fish out, drain and dry in the sun. Place it in an oven at 105±5°C and bake for 2.5 hours, take it out and place it in a fast shearing machine to cut and pulverize it, and collect the raw material powder through a 100-mesh sieve for future use.

[0029] (2) Catalyst preparation

[0030] Throw 10g of natural mordenite with a particle size of 0.1-5mm and a porosity of 36% into 100mL of 0.2mol / L Fe(NO 3 ) 2 solution or 100mL 0.2mol / LNi(NO 3 ) 3 After soaking in the solution for 30 minutes, send the soaked natural mordenite to a muffle furnace for calcination at 650° C. for 2 hours. Obtain catalyst FeM, NiM, standby.

[0031] (3) Bio-oil preparation

[0032] 1. Take 10g of algae raw material powder, add it to 100mL 0.1mol / L NaOH solution and soak for 24h; then put it into the autoclave together with 0.3g Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com