Method for increasing heavy oil yield by treating biological crude oil with ultrasonic wave

A bio-crude oil and ultrasonic technology, which is applied in the preparation of liquid hydrocarbon mixtures, only multi-stage series refining process treatment, petroleum industry, etc., can solve the problems that the ultrasonic extraction effect cannot be uniformly measured, and achieve good environmental protection and high-efficiency extraction effects , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

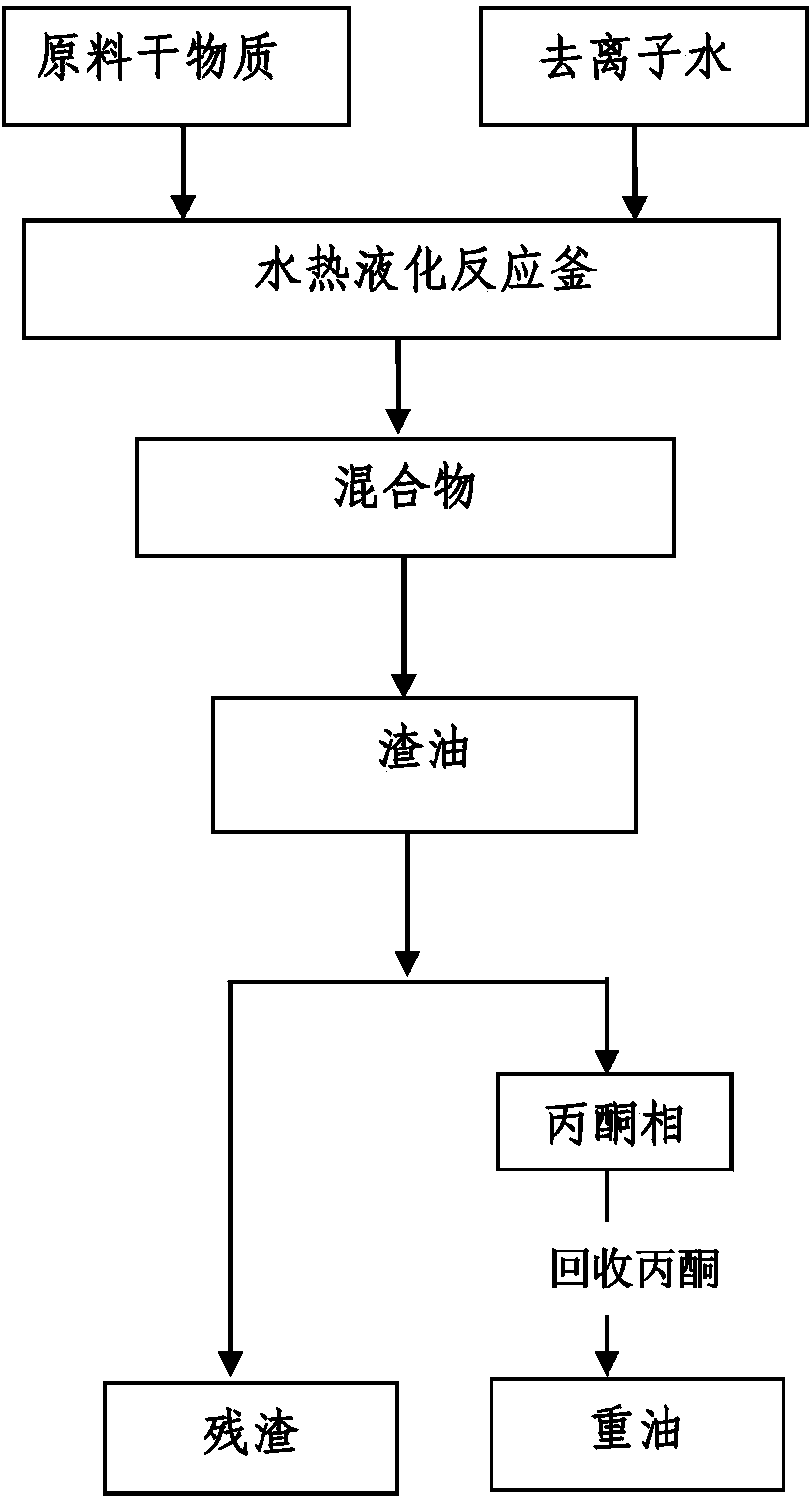

[0038] Take a certain amount of raw material dry matter and mix it with deionized water, so that in the obtained mixed solution, the mass percentage of raw material dry matter is 25%. The above mixed solution is charged into a hydrothermal liquefaction reactor.

[0039] In this embodiment, the hydrothermal liquefaction reactor adopts a batch reactor.

[0040] In this example, spirulina powder was used as raw material dry matter. The preparation method is as follows: Weigh 4°C frozen spirulina powder (screened to 200 mesh, ash content 5.7%), and thaw at 45°C.

[0041]Adjust the sealed reactor, fill it with nitrogen (volume concentration of 99.98%) to remove the air in the reactor, and make the pressure inside the reactor reach the initial pressure of 0.6MPA, start the agitator, and control the speed at 380rpm. After checking the air tightness , start the heating reaction. The temperature is controlled at 300° C., and the reaction time is 60 minutes.

[0042] After the react...

Embodiment 2

[0047] Take a certain amount of raw material dry matter and mix it with deionized water, so that in the obtained mixed solution, the mass percentage of raw material dry matter is 25%. The above mixed solution is charged into a hydrothermal liquefaction reactor.

[0048] In this embodiment, the hydrothermal liquefaction reactor adopts a batch reactor.

[0049] In this example, spirulina powder was used as raw material dry matter. The preparation method is as follows: Weigh 4°C frozen spirulina powder (screened to 200 mesh, ash content 5.7%), and thaw at 45°C.

[0050] Adjust the sealed reactor, fill it with nitrogen (volume concentration of 99.98%) to remove the air in the reactor, and make the pressure inside the reactor reach the initial pressure of 0.6MPA, start the agitator, and control the speed at 380rpm. After checking the air tightness , start the heating reaction. The temperature is controlled at 300° C., and the reaction time is 60 minutes.

[0051] After the reac...

Embodiment 3

[0056] Take a certain amount of raw material dry matter and mix it with deionized water, so that in the obtained mixed solution, the mass percentage of raw material dry matter is 25%. The above mixed solution is charged into a hydrothermal liquefaction reactor.

[0057] In this embodiment, the hydrothermal liquefaction reactor adopts a batch reactor.

[0058] In this example, spirulina powder was used as raw material dry matter. The preparation method is as follows: Weigh 4°C frozen spirulina powder (screened to 200 mesh, ash content 5.7%), and thaw at 45°C.

[0059] Adjust the sealed reactor, fill it with nitrogen (volume concentration of 99.98%) to remove the air in the reactor, and make the pressure inside the reactor reach the initial pressure of 0.6MPA, start the agitator, and control the speed at 380rpm. After checking the air tightness , start the heating reaction. The temperature is controlled at 300° C., and the reaction time is 60 minutes.

[0060] After the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com