Two-section type single loop mixed refrigerant natural gas liquefaction process and device

A technology for mixing refrigerant and natural gas, which is applied in the field of two-stage single-cycle mixed refrigerant natural gas liquefaction process and equipment, can solve problems such as complex process and complex process, and achieve the effects of simple process process, simple process and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

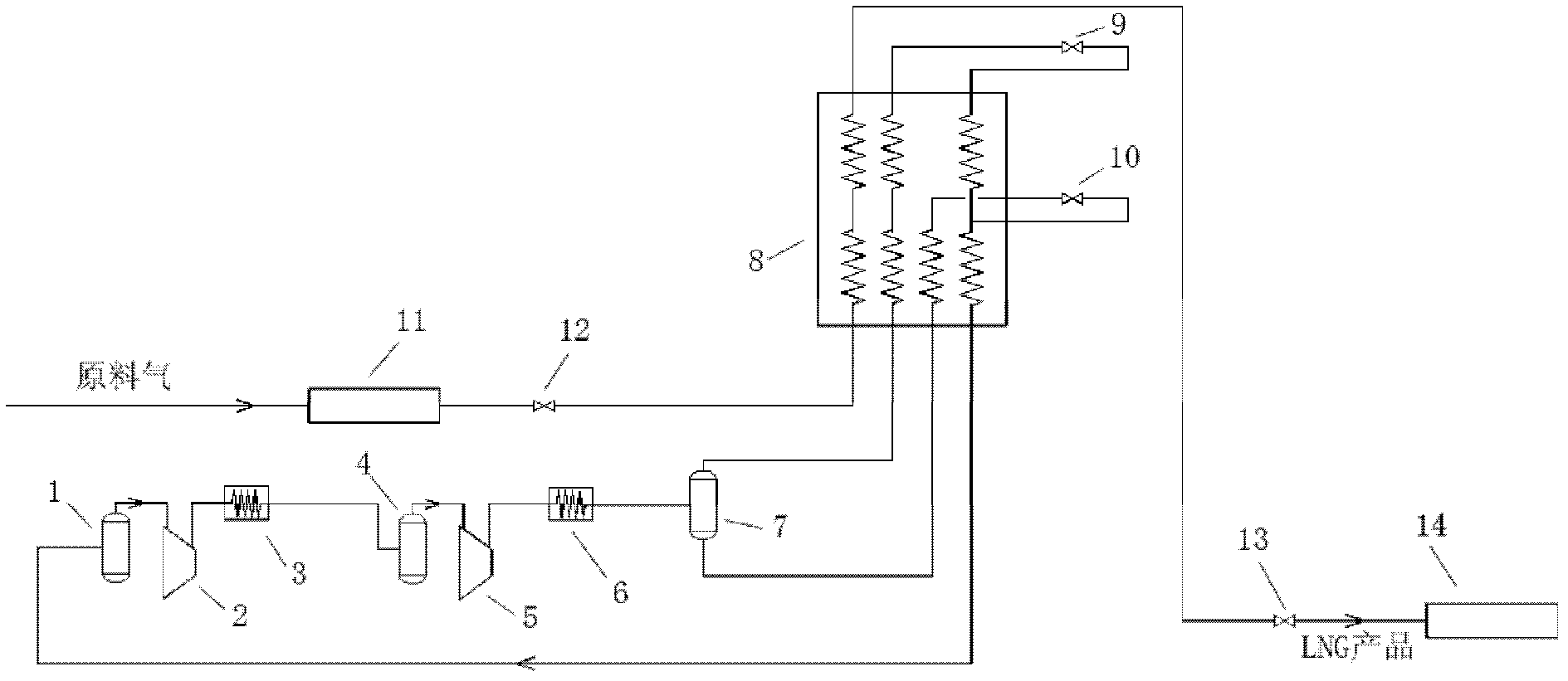

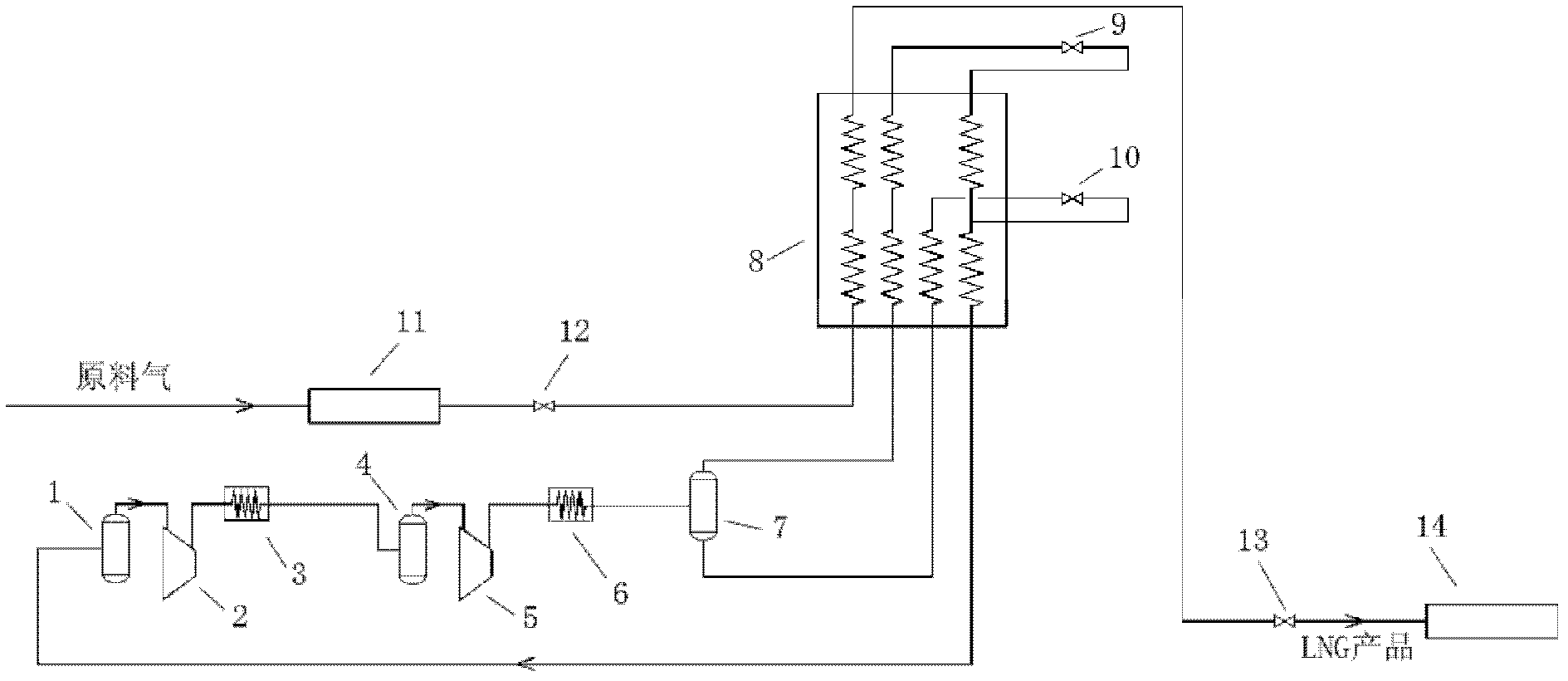

[0058] This embodiment provides a two-stage single-cycle mixed refrigerant natural gas liquefaction equipment, the structure of which is as follows figure 1 As shown, the natural gas liquefaction equipment includes: a first suction tank 1, a first compressor 2, a first cooler 3, a second suction tank 4, a second compressor 5, a second cooler 6, and a gas-liquid separation tank 7 , plate-fin cold box 8, first throttle valve 9, second throttle valve 10, wherein:

[0059] The plate-fin cold box 8 adopts an aluminum brazed plate-fin low-temperature heat exchanger, which is equipped with four flow channels, such as figure 1 As shown, the leftmost is the first flow channel (natural gas pipeline), and then from left to right are the second flow channel, the third flow channel, and the fourth flow channel;

[0060] Both the first compressor 2 and the second compressor 5 use two-stage compression centrifugal hybrid refrigerator compressors;

[0061] The first cooler 3 and the second ...

Embodiment 2

[0074] This embodiment provides a two-stage single-cycle mixed refrigerant natural gas liquefaction process, which is a natural gas liquefaction process using the equipment provided in Embodiment 1, including the following specific steps:

[0075] The mixed refrigerant with a pressure of 350kPa to 450kPa (preferably 420kPa) is compressed by the first compressor 2 to the range of 600kPa to 1000kPa (preferably 847kPa), and then cooled to 25°C to 45°C by the first cooler 3 (with ambient temperature), then inhaled by the second suction tank 4, then compressed into the second compressor 5 to 3500kPa to 4500kPa (preferably 4080kPa), and then cooled to 25°C to 45°C by the second cooler 6 (with ambient temperature related);

[0076] At this time, the mixed refrigerant is a gas-liquid two-phase, and after being input into the gas-liquid separation tank 7 for gas-liquid separation, a gas-phase refrigerant and a liquid-phase refrigerant are obtained, and the two are processed separately:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com