Natural gas liquefying method for gas peak regulation and light hydrocarbon recovery

A light hydrocarbon recovery and natural gas technology, which is applied in the field of natural gas liquefaction, can solve the problems of low cold energy utilization rate, complex process, and lower process liquefaction rate, and achieve the effects of improving utilization efficiency, optimizing heat exchange network, and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

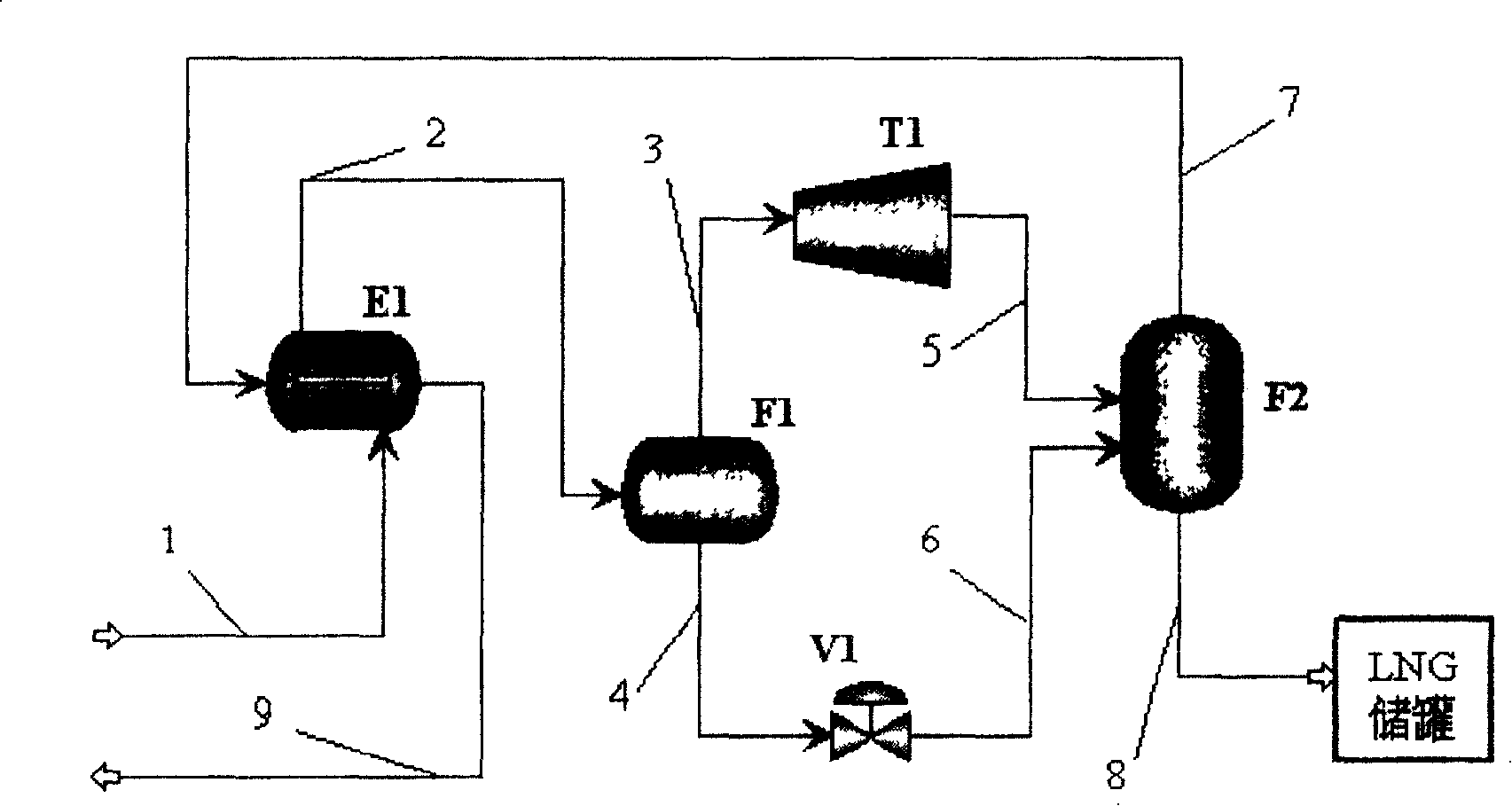

Embodiment 1

[0045] figure 2 Shows a specific process of the present invention, by figure 2 It can be seen that the specific natural gas liquefaction method is: the pressure is 4.0MPa, the temperature is 25℃, and the flow rate is 68258Nm. 3 / h (about 50t / h) of natural gas (raw gas) is sent to the heat exchanger E1 through the pipeline 1. The source of natural gas is the gasification of imported LNG dry gas, and its composition is as follows:

[0046] Composition content mol%

[0047] Methane 96.60

[0048] Ethane 1.97

[0049] Propane 0.40

[0050] Isobutane 0.07

[0051] N-butane 0.07

[0052] C 5 + Nil

[0053] Nitrogen 0.89

[0054] The raw material gas is pre-cooled in the heat exchanger E1 and is cooled to about -77.0°C. Some natural gas liquid is precipitated to form a gas-liquid mixture, and the gas phase fraction in the fluid is about 98%. Then, the gas-liquid mixture is sent to the gas-liquid separator F1 through the pipeline 2 for separation. Perform isostatic adiabatic separ...

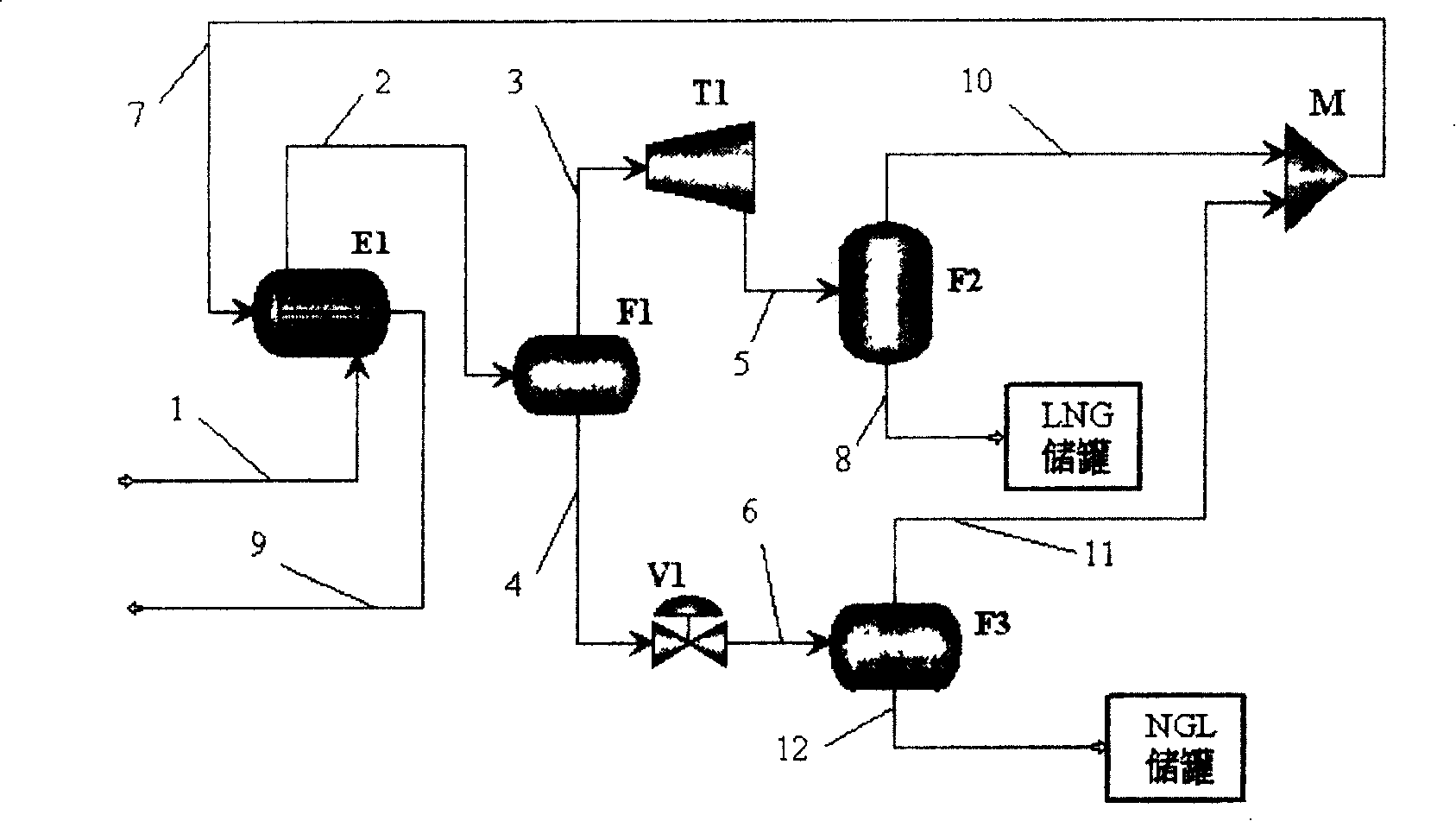

Embodiment 2

[0071] image 3 Shows another specific process of the present invention, by image 3 It can be seen that the natural gas liquefaction method is specifically as follows: pressure is 2.5MPa, temperature is 25℃, and flow rate is 68258Nm 3 / h (about 50t / h) of natural gas (raw gas) is sent to the heat exchanger E1 through the pipeline 1. The source of natural gas is the gasification of imported LNG dry gas, and its composition is the same as in Example 1.

[0072] The raw material gas is pre-cooled in the heat exchanger E1 and cooled to -92.0°C. Some natural gas liquid is precipitated to form a gas-liquid mixture, and the gas phase fraction in the fluid is 96%. Then, the gas-liquid mixture is sent to the gas-liquid separator F1 through the pipeline 2 for iso-pressure adiabatic separation. The natural gas of 2.5MPa and -92.0°C is separated from the top of the F1 tower and sent to the turboexpander T1 through pipeline 3 for expansion and pressure reduction. The high-pressure natural gas...

Embodiment 3

[0088] Figure 4 Another specific process of the present invention is shown: a certain place uses natural gas from the "West-East Gas Pipeline" and adopts two-stage pressure regulation. In the first stage of pressure regulation, the ultra-high pressure natural gas has been reduced to 1.9MPa, and then sent to the downstream area by pipeline. The downstream secondary pressure regulating station needs to reduce the pressure of the 1.9MPa high-pressure natural gas to 0.3MPa, and then send the natural gas to the user. The composition of "Western Gas" is shown in the following table. Due to the high content of acid gas, it is used in its secondary pressure regulating station. Figure 4 The liquefaction process shown has a processing capacity of 64731Nm 3 / h (about 50t / h).

[0089] Composition content mol%

[0090] Methane 94.10

[0091] Ethane 1.77

[0092] Propane 0.30

[0093] Isobutane 0.06

[0094] N-butane 0.02

[0095] Isopentane 0.02

[0096] N-pentane 0.02

[0097] C 6 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com