Processing method for starchiness materials and application of processing method in citric acid preparing industry

A technology for starchy raw materials and processing methods, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems that restrict the application of citric acid wastewater reflux process, unfavorable fermentation and citric acid purification, and cannot meet high temperature amylase. and other problems, to achieve the effect of shortening the liquefaction residence time, shortening the seed cultivation cycle, and shortening the raw material processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

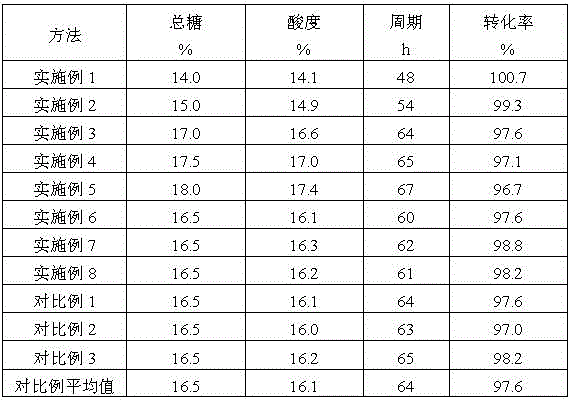

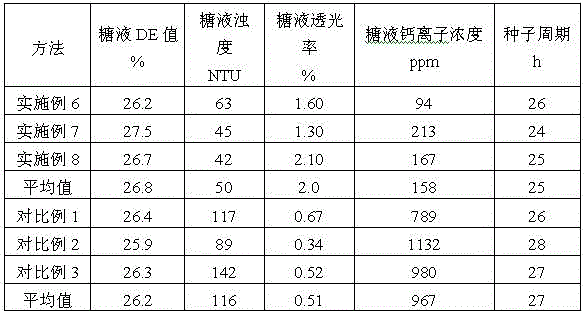

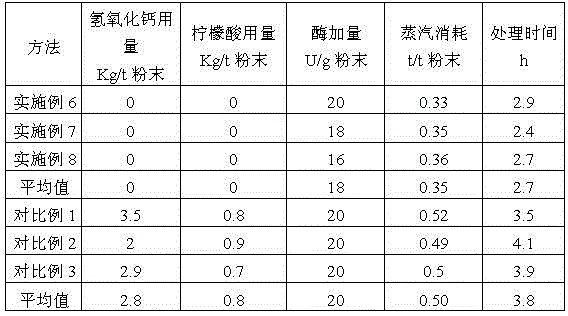

Examples

Embodiment 1

[0035] After crushing the corn, pass through a 80-mesh sieve; the obtained corn flour is evenly mixed with the neutralized waste sugar water and condensed water, so that the concentration of the slurry reaches 20%. A large amount of acid-resistant α-high temperature amylase was added; the obtained powder slurry was first sprayed at 105°C, then cooled to 97°C by flash evaporation, and kept for 3 hours. After the iodine test turned light brown, a qualified liquefied liquid was obtained; 70% of the liquefied liquid was passed through a plate Box filter to remove filter residue to obtain sugar solution.

[0036] Seed medium preparation: mix the liquefied liquid with tap water, dilute the total sugar concentration to 8%, add corn steep liquor to make the total nitrogen 0.15%, and prepare the seed medium; heat to 121°C, keep warm for 15min, cool down to 39°C, Inoculate Aspergillus niger spores for seed culture.

[0037] Seed culture conditions: temperature 37°C, control the oxygen ...

Embodiment 2

[0041] After crushing the corn, pass it through an 80-mesh sieve; mix the obtained corn flour with tap water, neutralized waste sugar water and chromatographic residue evenly, so that the concentration of the slurry reaches 28%. Add acid-resistant α-high temperature amylase to the amount of powder added; the obtained powder slurry is first sprayed at 108°C, then flashed and cooled to 99°C, and kept for 2 hours. After the iodine test is light brown, a qualified liquefied liquid is obtained; 75% of the liquefied The liquid is filtered through a plate frame to remove the filter residue to obtain the sugar liquid.

[0042]Seed medium preparation: mix the liquefied liquid with tap water, dilute the total sugar concentration to 8.5%, without adding other, and the total nitrogen is 0.18%, and prepare the seed medium. Heat to 121°C, keep warm for 15 minutes, cool down to 39°C, insert Aspergillus niger spores for seed culture.

[0043] Seed culture conditions: temperature 37°C, contro...

Embodiment 3

[0047] After crushing the corn, pass it through a 100-mesh sieve; mix the obtained corn flour with neutralized waste sugar water and chromatographic residual liquid evenly to make the slurry concentration reach 25%, and add 30U / g corn flour under the condition of pH 4.5-4.8 Acid-resistant α-high temperature amylase was added in a large amount; the obtained slurry was sprayed at 102°C, then flashed and cooled to 97°C, and kept for 2 hours, and the qualified liquefied liquid was obtained after the iodine test turned light brown; 80% of the liquefied liquid was passed through the plate frame Remove the filter residue by filtration to obtain sugar solution.

[0048] Seed medium preparation: mix the liquefied liquid with tap water, dilute the total sugar concentration of the mixture to 10%, add ammonium nitrate to make the total nitrogen 0.3%, and prepare the seed medium; heat to 121°C, keep warm for 15min, and cool down to 39°C ℃, inoculate Aspergillus niger spores for seed cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com