Preparation of novel acrylamide high-polymer chelating agent and application thereof to stabilization treatment of hazardous waste

A technology of polymer chelating agent and hazardous waste, applied in the field of new polymer chelating agent, to achieve the effect of low price and strong water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

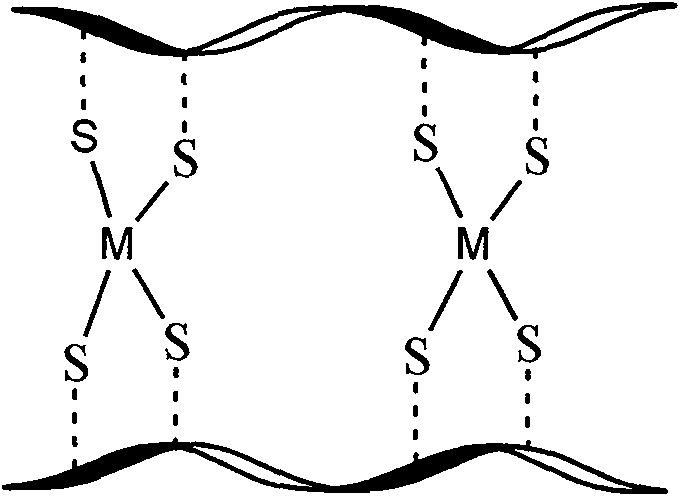

AI Technical Summary

Problems solved by technology

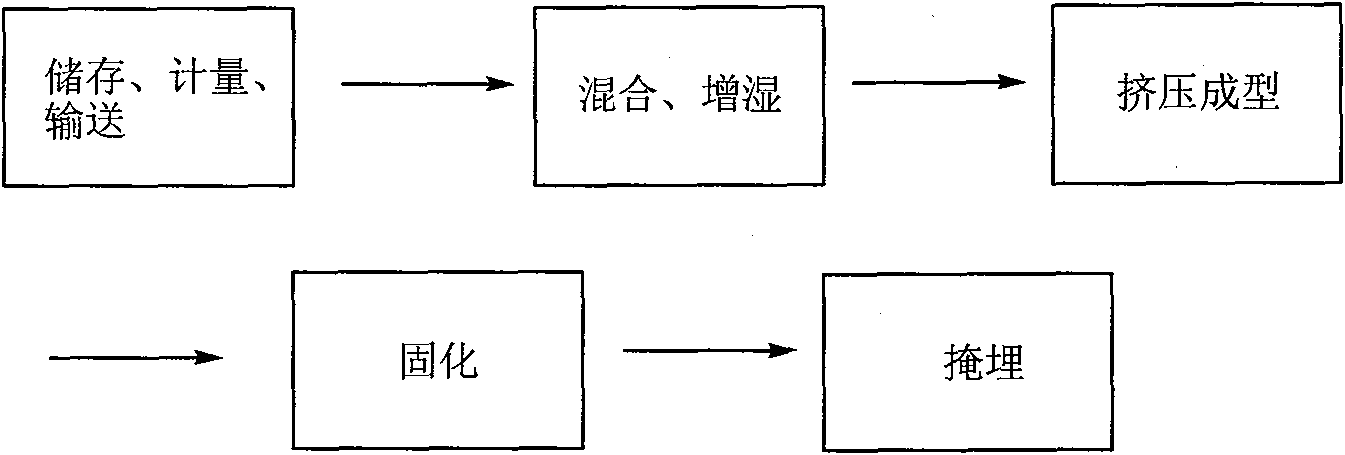

Method used

Image

Examples

Embodiment 1

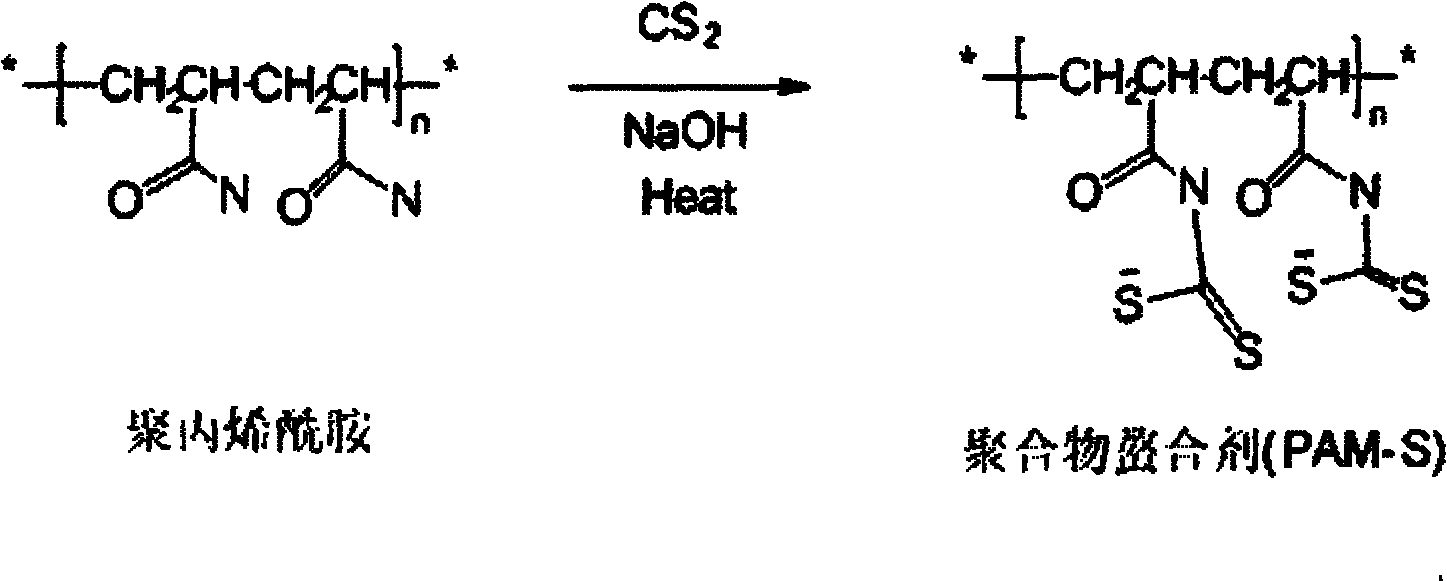

[0010] (1) Preparation of polymer chelating agent:

[0011] Commercially available polyacrylamides can be anionic polyacrylamide (APAM), cationic polyacrylamide (CPAM), nonionic polyacrylamide (NPAM), zwitterionic polyacrylamide (ACPAM). The molecular weight is between 2 million and 10 million.

[0012] Add 70g of polyacrylamide, 40g of NaOH, and 500mL of water into the reactor. Stir to mix well and heat to 80°C for 1 hour. Cool to 40°C, add 70 g of carbon disulfide dropwise, and continue stirring for 10 hours after the dropwise addition to obtain a brown transparent solution. Cool to room temperature to obtain an aqueous solution of polymer chelating agent.

[0013] (2) Utilize above-mentioned chelating agent to the processing experiment of incineration fly ash:

[0014] Literature at home and abroad show that the leaching concentration of incineration fly ash exceeds the standard is mainly lead. In a certain city incineration fly ash solidification enterprise, the conten...

Embodiment 2

[0019] (1) Preparation of polymer chelating agent:

[0020] Commercially available polyacrylamides can be anionic polyacrylamide (APAM), cationic polyacrylamide (CPAM), nonionic polyacrylamide (NPAM), zwitterionic polyacrylamide (ACPAM). The molecular weight is between 2 million and 10 million.

[0021] Add 70g of polyacrylamide, 80g of NaOH, and 1L of water into the reactor. Stir to mix well and heat to 80°C for 1 hour. Cool to 40°C, add 140 g of carbon disulfide dropwise, and continue stirring for 10 hours after the dropwise addition to obtain a brown transparent solution. Cool to room temperature to obtain an aqueous solution of polymer chelating agent.

[0022] (2) Utilize above-mentioned chelating agent to the processing experiment of incineration fly ash:

[0023] Also adopt the incineration fly ash of a city incineration fly ash solidification enterprise in the implementation 1, use the above-mentioned chelating agent to carry out the incineration fly ash solidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com