Preparation method and application of acrylamide modified grafted corn cob

A technology of acrylamide and graft modification, which is applied in the chemical field to achieve good development and application prospects, benefit environmental protection, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

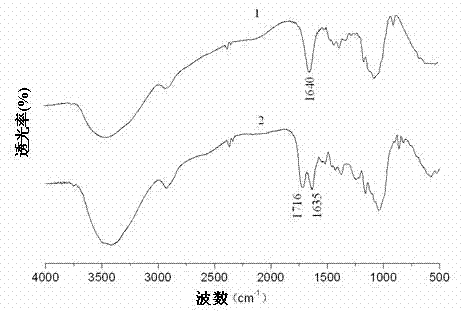

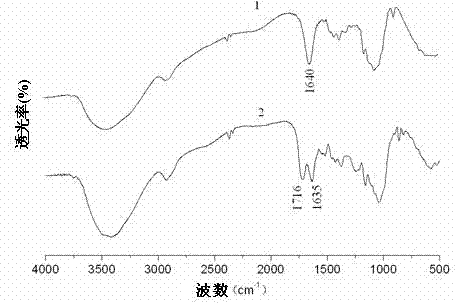

Image

Examples

Embodiment 1~10

[0024] Examples 1-10, preparation of acrylamide graft modified corncob (optimized condition of maleic acid modified corncob) and investigation of flocculation performance

[0025] General method of preparation: Add 4.0 g of corn cob powder and 500 mL of sodium hydroxide solution with a mass fraction of 20% in a pressure cooker, cook for 4 hours at a temperature of 120 °C and a pressure of 0.11 MPa, filter with suction, and vacuum-dry the filter cake at a temperature of 60 °C to constant weight , to obtain alkalized corncob; add alkalized corncob 1.0g and toluene in a 250mL three-necked flask X 1 mL, set temperature X 2 ℃ Soak in water bath X 3 hours, then add maleic anhydride X 4 g of acetone solution 5mL, at temperature X 5 ℃ reaction X 6 minutes, cooled to room temperature, washed 3 times with acetone, and dried to obtain maleic anhydride modified corncobs; add 0.5g of maleic anhydride modified corncobs and 70mL of water into a 250mL four-neck flask, and heat ...

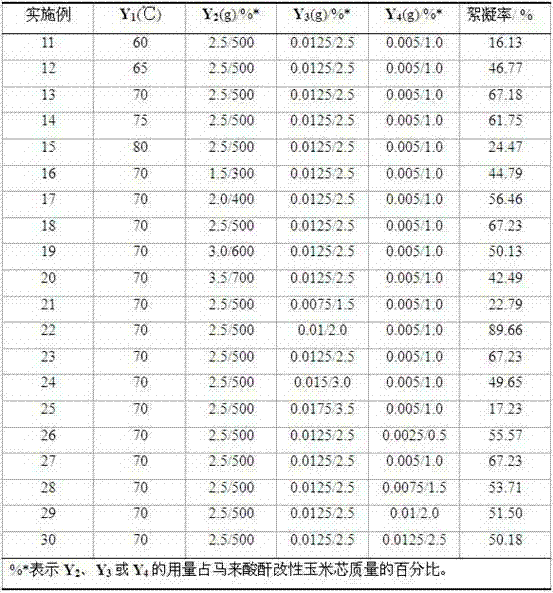

Embodiment 11~30

[0031] Examples 11~30, preparation of acrylamide graft modified corn cob (optimization of graft copolymerization conditions of acrylamide and maleic anhydride modified corn cob) and investigation of flocculation performance

[0032] General method of preparation: Add 4.0 g of corn cob powder and 500 mL of sodium hydroxide solution with a mass fraction of 20% in a pressure cooker, cook for 4 hours at a temperature of 120 °C and a pressure of 0.11 MPa, filter with suction, and vacuum-dry the filter cake at a temperature of 60 °C to constant weight , to obtain alkalized corncobs; add 1g of alkalized corncobs and 20mL of toluene into a 250mL three-necked flask, soak in a water bath at a temperature of 40°C for 5 hours, then add 10mL of acetone solution of 0.4g of maleic anhydride, and react at a temperature of 80°C After 90 minutes, cool to room temperature, wash 3 times with acetone, and dry to obtain maleic anhydride modified corncobs; add maleic anhydride modified corncobs 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com