A kind of method of producing injection maltose crude drug

A technology of maltose and maltotriose enzyme, which is applied in the direction of pharmaceutical formulations, chemical instruments and methods, disaccharides, etc., can solve the problems of high price, high-purity crystalline maltose production started late, and achieve good granularity, easy separation of mother liquor, The effect of increasing the amount of seed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

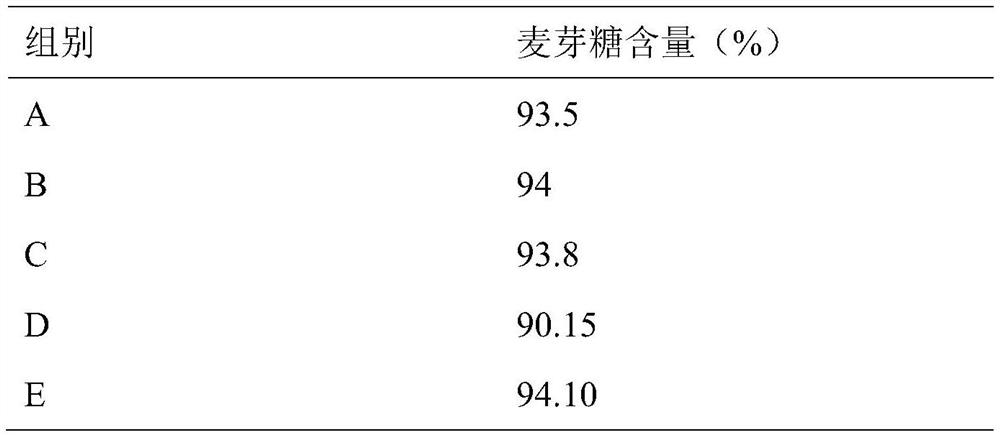

Embodiment 1

[0037]Weigh 430g of cornstarch, make it into a volume of 2000mL with tap water, adjust the pH to 5.8 with hydrochloric acid, add 120 μL of high-temperature-resistant amylase, heat and liquefy in a water bath, keep it at 98°C for 15 minutes, adjust the pH to 4.0 with hydrochloric acid to inactivate the enzyme, and then Cool down to 60°C, add 5% NaOH to adjust the pH to 5.51, and obtain maltodextrin with a DE value of 5-6. Add 600 μL of pullulanase, 400 μL of Beta amylase, and 600 μL of maltotriose. After saccharifying at 60°C for 40 hours in a water bath, add 10 μL of medium-temperature amylase and 10 μL of glucoamylase, and keep saccharifying at 60°C for 12 hours. The maltose content is 94.2% detected by liquid phase, the temperature is raised to inactivate enzymes, activated carbon is added to decolorize, and filter paper is filtered to make the sugar solution clear and transparent, free of foreign matter and impurities visible to the naked eye. After passing through the anion...

Embodiment 2

[0039] It uses commercial maltodextrin (DE value 6-8) as raw material. Weigh 400g of commercial maltodextrin, make it into a volume of 2000mL, adjust the pH to 5.6, add 600μL of maltotriose, 600μL of pullulanase, and 400μL of Beta amylase, keep warm and saccharify in a water bath for 40 hours, then add medium temperature starch Enzyme 10μL, glucoamylase 10μL, keep warm and saccharify for 12 hours, sample liquid phase to detect maltose content 93.8%, heat up to inactivate enzyme, add activated carbon to decolorize, filter paper, pass through anion and cation exchange resin, conductivity 26μs / cm, concentrated to 72.5% , Stir and crystallize in a beaker, adopt the previous semi-crystallization process, cool down and crystallize in a water bath in a beaker, use a model IS-11 experimental centrifuge to separate, produce 181g of tidal sugar, mother liquor 45% concentration 405g, and dry in an oven 168g of finished crystalline maltose was obtained by sieving, and the quality inspecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com