Preparation method for chitosan modified algae removal flocculant

A chitosan modification and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, polluted waterway/lake/pond/river treatment, etc., can solve the problem of low chitosan charge density. , limited widespread use, poor bridging ability, etc., to achieve the effect of improving cation strength, improving solubility, and improving flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

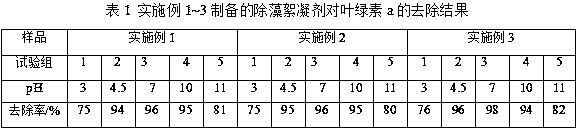

Examples

Embodiment 1

[0034] The preparation method of the present embodiment chitosan modified algae-removing flocculant comprises the steps:

[0035] In the first step, 7.64 g (0.047 mol) of chitosan powder was added to 10 mL of acetic acid solution with a mass concentration of 1%, and placed on a magnetic stirrer to stir until dissolved, and then slowly added 10 mL of maleic anhydride aqueous solution, of which Toric anhydride is 4.589g (0.047mol), stirred with a magnetic stirrer until the solution is uniform and transparent, and a slightly yellow solution. The obtained homogeneous and transparent solution was placed in a water-bath shaker, shaken at 30° C. for 7 hours, and dried at 40° C., and the obtained product was maleylated chitosan.

[0036] In the second step, add 2g of maleylated chitosan, 30ml of deionized water, 6g of acrylamide (AM), and 2g of dimethyldiallyl ammonium chloride (DMDAAC) to the quartz reactor, and stir well To completely dissolve to form a homogeneous aqueous solution...

Embodiment 2

[0040] The preparation method of the present embodiment chitosan modified algae-removing flocculant comprises the steps:

[0041] In the first step, add 9.821g (0.061mo) of chitosan powder to 15mL of acetic acid solution with a mass concentration of 4%, and place it on a magnetic stirrer to stir until dissolved, then slowly add 20mL of maleic anhydride aqueous solution, of which The amount of toic anhydride is 5.892g (0.059mol). Stir with a magnetic stirrer until the solution is uniform and transparent, and a slightly yellow solution. The obtained homogeneous and transparent solution was placed in a water-bath shaker, shaken at 40° C. for 5 hours, and dried at 40° C., and the obtained product was maleylated chitosan.

[0042]In the second step, 3 g of maleylated chitosan monomer, 25 ml of deionized water, 5 g of acrylamide (AM), and 2 g of dimethyl diallyl ammonium chloride (DMDAAC) were sequentially added to the quartz reactor. Stir evenly to completely dissolve and form a h...

Embodiment 3

[0046] The preparation method of the present embodiment chitosan modified algae-removing flocculant comprises the steps:

[0047] The first step is to add 7.64g of chitosan powder to 25mL of acetic acid solution with a mass concentration of 2%, and place on a magnetic stirrer to stir until dissolved, then slowly add 40mL of maleic anhydride aqueous solution, wherein maleic anhydride is 4.589 g, stir with a magnetic stirrer until the solution is uniform and transparent, and a slightly yellow solution. The obtained homogeneous and transparent solution was placed in a water-bath shaker, shaken at 30° C. for 7 hours, and dried at 40° C., and the obtained product was maleylated chitosan.

[0048] In the second step, add 2 g of maleylated chitosan monomer, 25 ml of deionized water, 6 g of acrylamide (AM), and 2 g of dimethyl diallyl ammonium chloride (DMDAAC) to the quartz reactor. Stir evenly to completely dissolve and form a homogeneous aqueous solution, wherein deionized water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com