High-efficiency flocculation-adsorption treatment method for waste water containing low-concentration organic arsine preparations

An adsorption treatment, organic arsine technology, applied in adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. The preparation method is simple, the water quality of the effluent is stable, and the raw materials are easily available.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

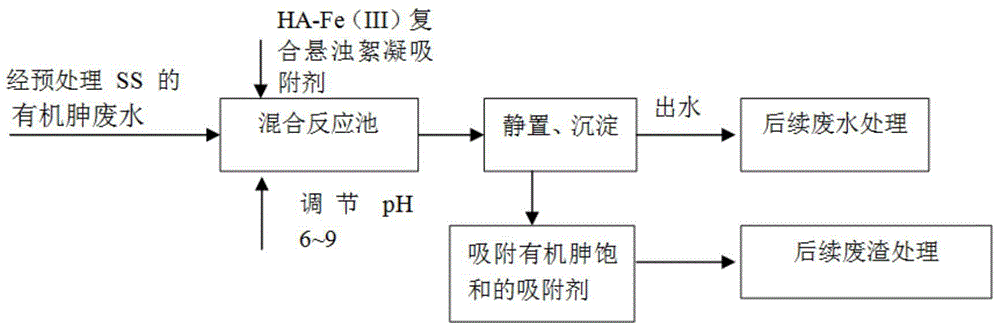

[0036] combine figure 1 , a kind of high-efficiency flocculation-adsorption method of the present embodiment containing low-concentration roxarsone waste water, its steps are:

[0037] Step 1. Preparation of humic acid-iron (Ⅲ) composite suspension flocculation-adsorbent:

[0038] In 0.2mol / L, 50mL iron (III) nitrate solution, add 50mL of 1g / L sodium humate solution (HA-Na) dropwise while stirring, the dropping speed is 10 drops per minute, and the stirring speed is 200rpm. After reacting at a temperature of 50-100° C. for 4-8 hours, let it stand for cooling to form a certain concentration of humic acid-iron (Ⅲ) composite suspension flocculation-adsorbent, and shake well before use.

[0039] Step 2: Use a common reactor with a stirring system, which is connected to a dosing system for the suspended adsorbent. The low-concentration roxarsone wastewater containing roxarsone concentration of 10mg / L is pretreated to remove most of the suspended solids in the wastewater and contr...

Embodiment 2

[0043] A kind of flocculation-adsorption treatment of the present embodiment contains the method for low-concentration arkanic acid (para-aminophenylarsine acid) waste water, and its steps are:

[0044] Step 1. Preparation of humic acid-iron (Ⅲ) composite suspension flocculation-adsorbent:

[0045] In 0.1mol / L, 50mL iron sulfate (III) solution, add dropwise 50mL of 3g / L potassium humate solution while stirring, the dropping speed is 5 drops per minute, and the stirring speed is 200rpm. After reacting at a temperature of 80-90°C for 4-8 hours, let it stand for cooling to form a certain concentration of humic acid-iron (Ⅲ) composite suspension flocculation-adsorbent, and shake well before use.

[0046] Step 2: Use a common reactor with a stirring system, which is connected to a dosing system for the suspended adsorbent. The low-concentration arsanic acid wastewater containing arsanic acid concentration of 50mg / L is pretreated to remove most of the suspended solids in the wastew...

Embodiment 3

[0050] A kind of flocculation-adsorption method of the present embodiment contains low concentration roxarsone waste water, and its steps are:

[0051] Step 1. Preparation of humic acid-iron (Ⅲ) composite suspension flocculation-adsorbent:

[0052] In 0.2mol / L, 50mL iron (III) nitrate solution, add 50mL of 5g / L humic acid solution dropwise while stirring, the dropping rate is 10 drops per minute, and the stirring speed is 200rpm. After reacting at a temperature of 50-100° C. for 4-8 hours, let it stand for cooling to form a certain concentration of humic acid-iron (Ⅲ) composite suspension flocculation-adsorbent, and shake well before use.

[0053] Step 2: Use a common reactor with a stirring system, which is connected to a dosing system for the suspended adsorbent. The low-concentration roxarsone wastewater containing 80mg / L roxarsone is pretreated to remove most of the suspended solids in the wastewater and control the suspended solids concentration to less than 50mg / L.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com