Preparation of immobilized enzyme and method for hydrolyzing diosgenin

A technology of diosgenin and immobilized enzymes, applied in the field of biomedicine, can solve problems such as environmental pollution, achieve the effects of reducing production costs, increasing conversion rates, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

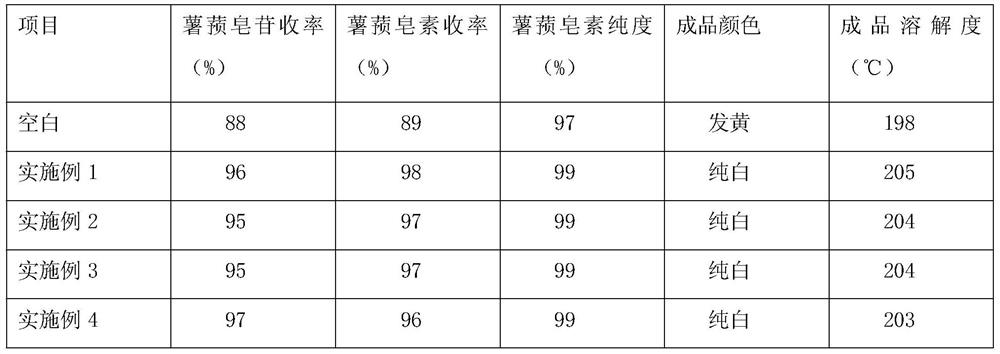

Examples

Embodiment 1

[0036] (1) 100kg of dry turmeric raw materials are pulverized, passed through a 20-mesh sieve, added to 300kg, and 20000IU of raw material amylase, 1000IU of pullulanase, and 100000IU of fungal α-amylase are added to the above-mentioned solution for enzymolysis;

[0037] (2) enzymatically hydrolyzing the turmeric aqueous solution in step (1) for 24h at natural temperature;

[0038] (3) Step (2) is subjected to solid-liquid separation, and the solid is extracted with 100 L of ethanol with a volume fraction of 75% to extract dioscin, extracting 3 times, each time for 30 minutes, and the liquid can be used to make alcohol;

[0039] (4) Preparation of immobilized enzyme preparation composition:

[0040] Add water to chitosan to prepare a solution with a concentration of 2g / L, stir it at a temperature of 10°C to dissolve it; then add β-glucosidase 12000IU and cascara with a mass ratio of 1:30 to chitosan Glycosidase 2000IU, stir evenly, place on a constant temperature shaker at 10...

Embodiment 2

[0044] (1) 100kg of dried turmeric raw materials are crushed, passed through a 20-mesh sieve, added to 300kg, 10000IU of raw material amylase, 5000IU of pullulanase, and 50000IU of fungal α-amylase are added to the above-mentioned solution for enzymolysis;

[0045] (2) enzymatically hydrolyzing the turmeric aqueous solution in step (1) for 24h at natural temperature;

[0046] (3) Step (2) is subjected to solid-liquid separation, and the solid is extracted with 100 L of ethanol with a volume fraction of 75% to extract dioscin, extracting 3 times, each time for 30 minutes, and the liquid can be used to make alcohol;

[0047] (4) Preparation of immobilized enzyme preparation composition:

[0048]Mix chitosan and non-polar macroporous resin at 1:1, add water to prepare a solution with a concentration of 2g / L, stir at a temperature of 10°C to dissolve it; then add chitosan with a mass ratio of 1:40 β-glucosidase 8000IU and rhamnosidase 5000IU, stir evenly, place on a constant temp...

Embodiment 3

[0052] (1) 100kg of dried turmeric raw materials are pulverized, passed through a 20-mesh sieve, added to 300kg, and 16000IU of raw material amylase, 2000IU of pullulanase, and 90000IU of fungal α-amylase are added to the above-mentioned solution for enzymolysis;

[0053] (2) enzymatically hydrolyzing the turmeric aqueous solution in step (1) for 24h at natural temperature;

[0054] (3) Step (2) is subjected to solid-liquid separation, and the solid is extracted with 100 L of ethanol with a volume fraction of 75% to extract dioscin, extracting 3 times, each time for 30 minutes, and the liquid can be used to make alcohol;

[0055] (4) Preparation of immobilized enzyme preparation composition:

[0056] Mix chitosan and non-polar macroporous resin polyacrylamide at a ratio of 1:1:1, add water to prepare a solution with a concentration of 2g / L, stir at a temperature of 10°C to dissolve it; then add shell β-glucosidase 10000IU and rhamnosidase 3000IU with a glycan mass ratio of 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com