Refrigerant recovery device

A refrigerant recovery and refrigerant gas technology, which is applied to refrigerants, refrigerators, refrigeration components, etc., can solve the problems of increased cost of Freon gas recovery and high operating costs, and achieves low recovery cost, shortened recovery time, and continuous refrigeration. The effect of agent recovery operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

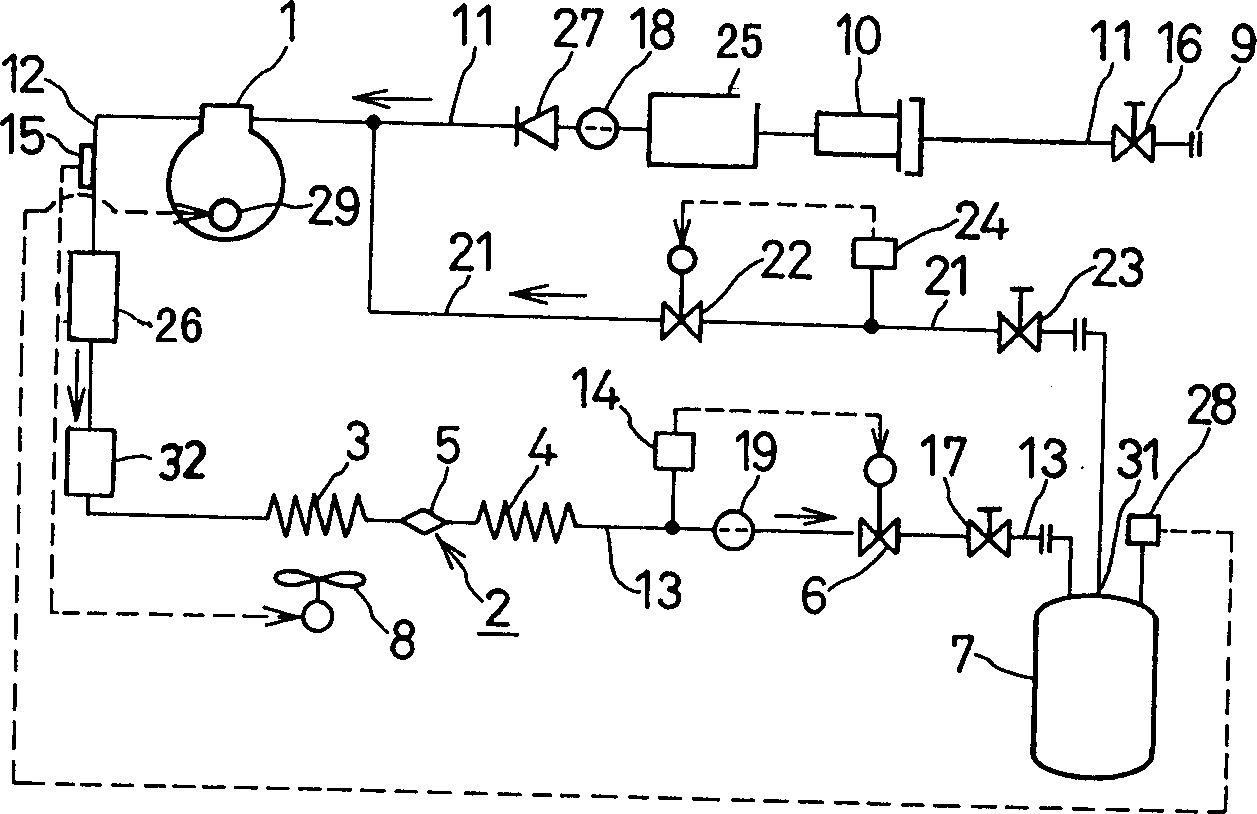

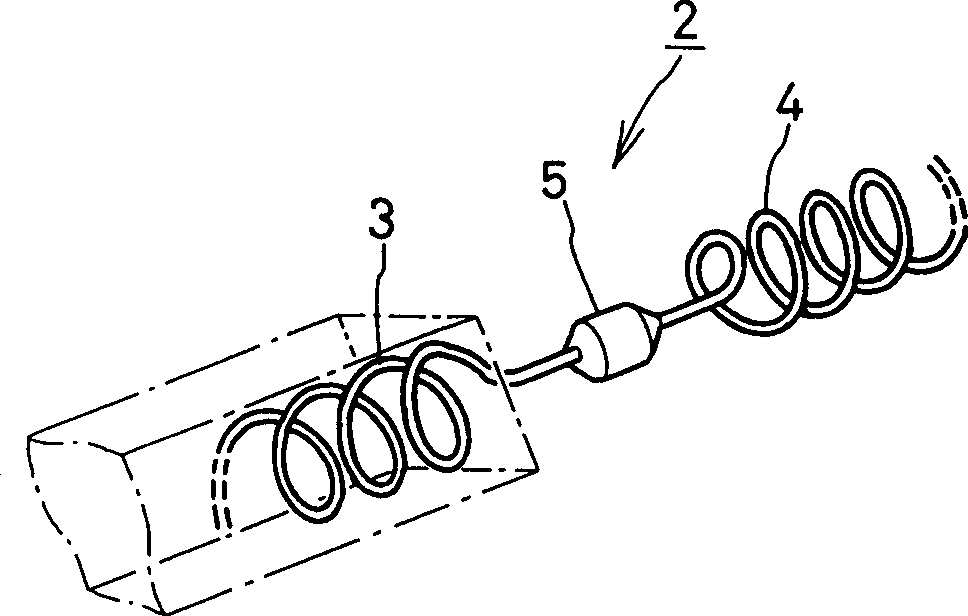

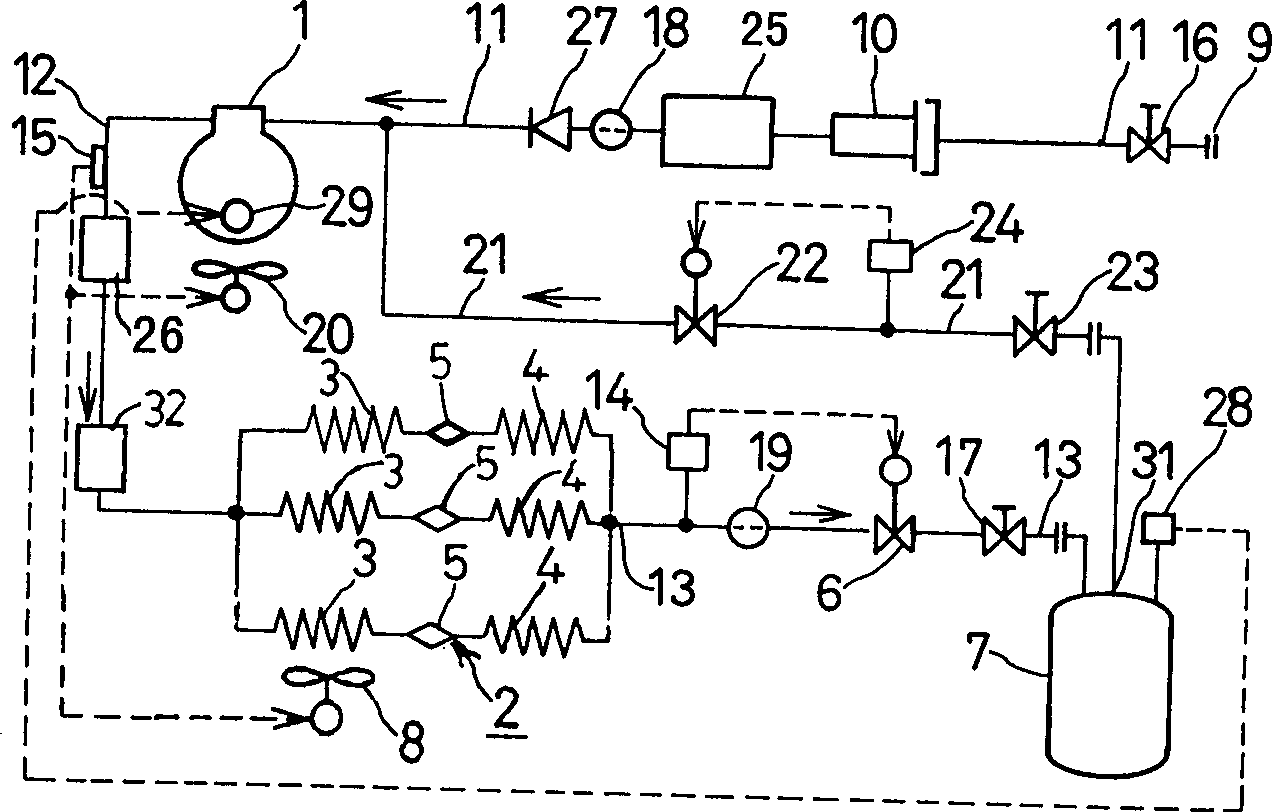

[0020] Hereinafter, preferred examples of embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic circuit diagram of the refrigerant recovery device according to the first embodiment of the present invention. in addition, figure 2 yes figure 1 It is a perspective view of the heat exchange device 2 in the refrigerant recovery device shown.

[0021] figure 1 The shown refrigerant recovery device has a compressor 1, a heat exchange device 2, a solenoid valve 6 and a refrigerant recovery tank 7 as main equipment, and these devices are connected by refrigerant pipelines of a suction pipe 11, a discharge pipe 12 and a liquid pipe 13. Connected to form a series circuit, thereby forming a device for effectively recovering the refrigerant - Freon gas.

[0022] Moreover, the above-mentioned refrigerant recovery device is equipped with a gas pipe 21 inserted with a solenoid valve 22, and becomes a bypass with respect to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com