Wood liquefied substance foamed material and preparation method thereof

A technology of foaming materials and liquefied substances, which is applied in the chemical industry, can solve problems such as pollution and recycling difficulties, and achieve the effects of simple process, wide source of raw materials, and improved comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

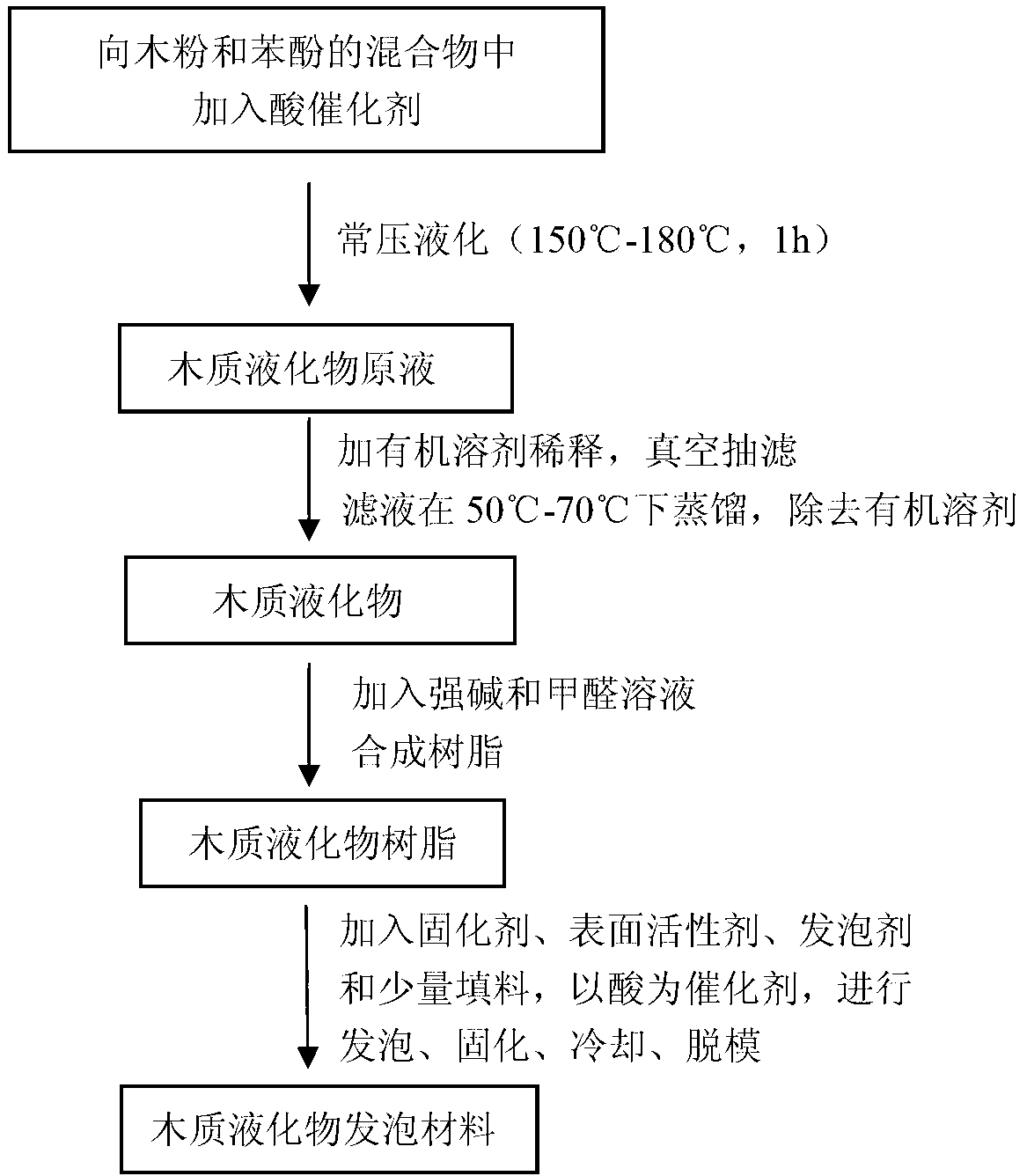

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of wood liquefied material foaming material

[0034] 1. Pulverize the woody material into a powder with a size of 40 meshes, add 3 times the weight of wood powder to the wood powder, add an acid catalyst at 3% of the weight of phenol, and start the agitator and condensing device under 98% sulfuric acid catalyzed conditions. Heating to 150°C in an oil bath, keeping the temperature for 1 hour to complete the liquefaction, and obtaining a black viscous wood liquefaction stock solution (see ZL 200710100365.1).

[0035] 2. Filtration of liquefied matter: the above stock solution was diluted by adding 40% 1,4-dioxane solution as a solvent according to the weight ratio, and then vacuum filtered with a G2 glass filter to obtain a filtrate. The filtrate was distilled at 50°C for 3 hours to remove the solvent 1,4-dioxane to obtain a woody liquefied product, which was placed in a three-necked flask.

[0036] 3. Synthesis of wood liquefaction resin: Add 40% s...

Embodiment 2

[0039] Example 2 Preparation of wood liquefied material foaming material

[0040] 1. Grind the woody material into powder with a size of 80 meshes, add phenol with 6 times the weight of wood powder to the wood powder, add acid catalyst according to 6% of the weight of phenol, and start the agitator and condensing device under the catalysis condition of 98% sulfuric acid, Heating to 180°C in an oil bath, keeping the temperature for 1.5 hours to complete the liquefaction, and obtaining a black viscous wood liquefaction stock solution (see ZL200710100365.1).

[0041] 2. Filtration of liquefied matter: the above stock solution was diluted by adding 40% dimethylformamide solution as a solvent according to the weight ratio, and then vacuum-filtered with a G2 glass filter to obtain a filtrate. The filtrate was distilled at 70°C for 3h, and the solvent dimethylformamide was removed to obtain a wood liquefaction, which was placed in a three-necked flask.

[0042] 3. Synthesis of wood li...

Embodiment 3

[0045] Example 3 Preparation of wood liquefied material foaming material

[0046] 1. Grinding the woody material into powder with a size of 50 meshes, adding 4 times the weight of wood powder to the wood powder, adding an acid catalyst at 4% of the weight of phenol, and starting the agitator and condensing device under 98% sulfuric acid catalysis conditions, Heating to 160°C in an oil bath, keeping the temperature for 1 hour to complete the liquefaction, and obtaining a black viscous wood liquefaction stock solution (see ZL 200710100365.1).

[0047] 2. Filtration of liquefied matter: the above stock solution was diluted by adding 40% dimethyl acetyl solution as a solvent according to the weight ratio, and then vacuum filtered with a G2 glass filter to obtain a filtrate. The filtrate was distilled at 60°C for 2 hours to remove the solvent dimethylacetyl to obtain a wood liquefaction, which was placed in a three-necked flask.

[0048] 3. Synthesis of wood liquefaction resin: Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com