Method for preparing foamed shoe material by blending cork powder with EVA (Ethylene Vinyl Acetate)

A technology of cork powder and blending, which is applied in the field of shoe material preparation, can solve the problems that are difficult to apply in the shoe industry, such as hard materials and lack of elasticity, and achieve the effect of unique appearance, excellent cushioning and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

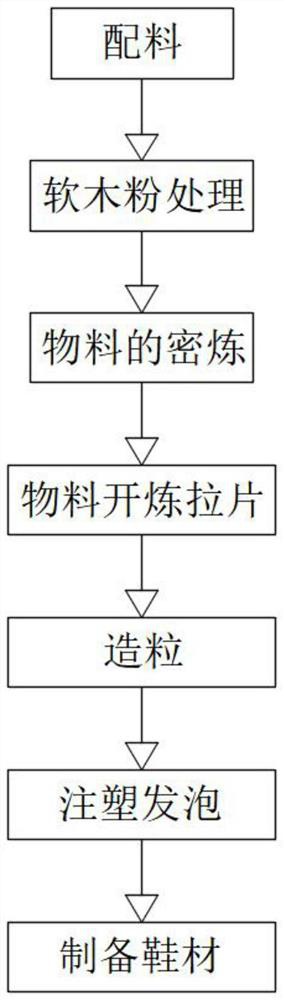

Method used

Image

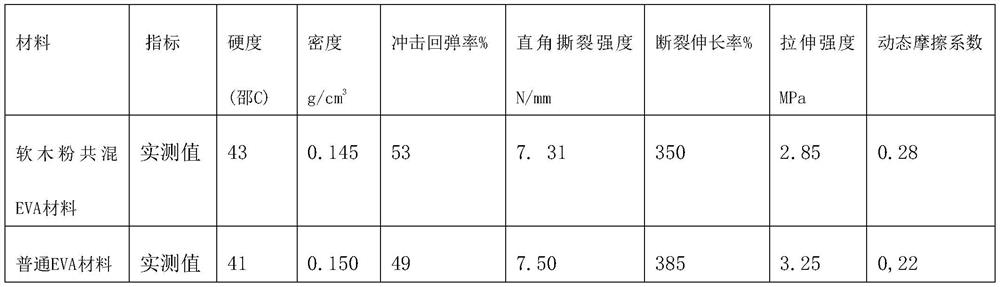

Examples

Embodiment 1

[0048] The first step of cork powder treatment: put 20-mesh cork powder in an oven, dry at 105°C for 6 hours to obtain cork powder with a moisture content of less than 5%, and weigh it.

[0049] The second step is the plasticization of cork powder: put 80 g of dried cork powder in a high-speed mixer, add 6502 g of plasticizer silane coupling agent and stir at high speed for 8 minutes.

[0050]In the third step, add EVA180g, POE10g and EPDM40g to the internal mixer, banbury for 4min at 115°C, add compatibilizer maleic anhydride modified EVA3g and banbury for 3min, then add 50g of plasticized cork powder in the second step, banbury for 5min After observing that the refining is basically uniform, add 3g of neutralizing additive sodium bicarbonate, 4g of additive zinc oxide, 4g of zinc stearate, 10g of foaming agent azodicarbonamide (AC), continue banburying for 4min, and add inorganic 20g of filler talcum powder continued banburying for 3min, then added 1.7g of cross-linking agen...

Embodiment 2

[0056] The first step of cork powder treatment: put 80-mesh cork powder in an oven, dry at 105° C. for 6 hours, obtain cork powder with a moisture content of less than 5%, and weigh it.

[0057] The second step is the plasticization of the cork powder: put 90 g of the dried cork powder in a high-speed mixer, add 6502 g of plasticizer silane coupling agent and stir at high speed for 8 minutes.

[0058] In the third step, add 180g of EVA, 10g of POE and 40g of EPDM to the internal mixer, banbury for 4min at 115°C, add compatibilizer maleic anhydride modified EVA2g for banburying for 3min, then add 60g of plasticized cork powder in the second step, banbury for 5min After observing that the refining is basically uniform, add 3g of neutralizing additive sodium bicarbonate, 4g of additive zinc oxide, 4g of zinc stearate, 8g of foaming agent azodicarbonamide (AC), continue banburying for 4min, and add inorganic 20g of filler talcum powder continued banburying for 3min, then added 1.8...

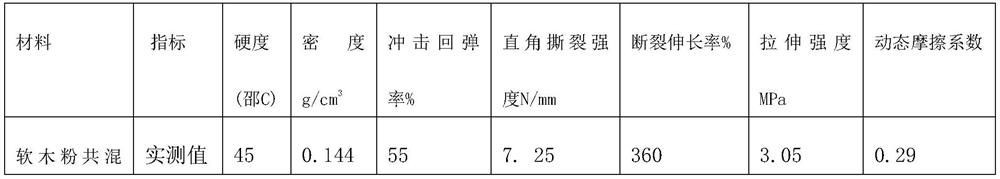

Embodiment 3

[0065] The first step of cork powder treatment: put 200-mesh cork powder in an oven, dry at 105° C. for 6 hours to obtain cork powder with a moisture content of less than 5%, and weigh it.

[0066] The second step is the plasticization of cork powder: put 100 g of dried cork powder in a high-speed mixer, add 6502 g of plasticizer silane coupling agent and stir at high speed for 8 minutes.

[0067] In the third step, add 180g of EVA, 10g of POE and 40g of EPDM to the internal mixer, banbury for 4min at 115°C, add compatibilizer maleic anhydride modified EVA1g and banbury for 3min, then add 90g of plasticized cork powder in the second step, banbury for 5min After observing that the refining is basically uniform, add 3g of neutralizing additive sodium bicarbonate, 4g of additive zinc oxide, 4g of zinc stearate, 9g of foaming agent azodicarbonamide (AC), continue banburying for 4min, and add inorganic 30g of filler talcum powder continued banburying for 3min, then added 1.9g of cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com