A flue gas treatment system and treatment method in a pvc glove production workshop

A flue gas treatment system and technology for production workshops, which are applied in chemical instruments and methods, cleaning methods and utensils, and smoke and dust removal, etc., can solve problems such as physical injury to workers and pollute the environment, achieve no secondary pollution, and reduce flue gas emissions. , Guarantee the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

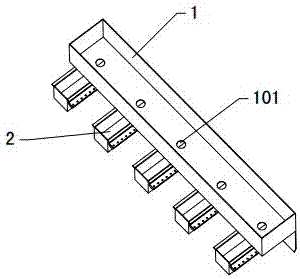

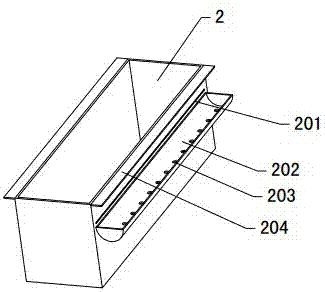

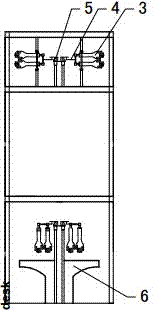

[0036] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0037] refer to Figure 1~2 , the flue gas treatment system of the PVC glove production workshop includes a glove mold line, a drying box and a trough. A spraying device is installed above the mold line of the baked gloves, and the spraying device is connected with a circulating water supply device. By spraying the gloves on the baked hand mold 3, the temperature of the gloves is reduced, and the temperature is controlled within 120°C. The volatilization temperature of the relevant components of PVC gloves cannot be reached, thereby reducing smoke emissions.

[0038] The circulating water supply device in this embodiment includes a circulating water pool and a circulating water pump, and the circulating water pool is connected to the circulating water pump and the spraying device through a circulating pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com